Bridge ductility anti-earthquake structure easy to replace after earthquake and construction method

A technology of anti-seismic structure and construction method, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of plate rubber bearing damage, damage, and difficulty in repairing after earthquakes, and achieve good lateral displacement, convenient replacement, and small damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

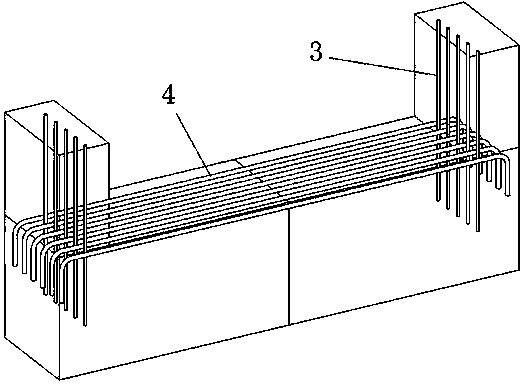

[0032] A ductile anti-seismic structure of a bridge that is easy to replace after an earthquake. The innovation is that the ductile anti-seismic structure of the bridge is composed of a base 1 and two anti-seismic blocks 2; the base 1 and the anti-seismic blocks 2 are both reinforced concrete structures, and the base 1 and the anti-seismic block 2 are relatively independent; the upper side of the base 1 is parallel to the horizontal plane, and the anti-seismic block 2 is arranged on the upper side of the base 1: the lower end surface of the anti-seismic block 2 is in contact with the upper side of the base 1, two The anti-seismic stoppers 2 are respectively located at both lateral ends of the base body 1; the anti-seismic stoppers 2 and the base body 1 are connected by a plurality of vertical shear bars 3: the axial direction of the vertical shear bars 3 is perpendicular to the upper side of the base body 1, and the vertical shear bars The upper part of the cut steel bar 3 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com