Tie rod ball joint assembly for lightweight automobile and preparation method thereof

A lightweight, tie rod technology, used in steering tie rods, vehicle parts, transportation and packaging, etc., can solve the problems of poor strength and heavy steel pipe quality, and achieve the goal of reducing friction, reducing mass, and enhancing tensile strength and yield strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

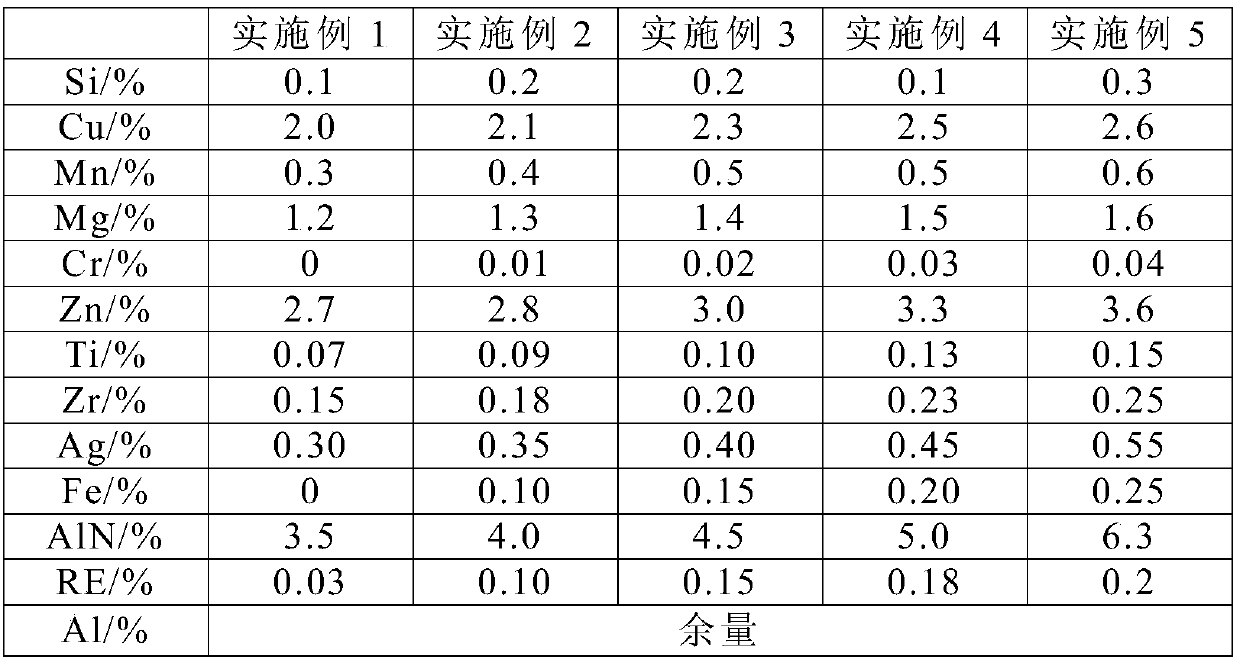

[0034] The tie rod ball joint assembly for lightweight automobiles in Examples 1 to 5, the tie rod ball joint assembly includes a tie rod connecting pipe and ball joint assemblies arranged at both ends of the tie rod connecting pipe and are symmetrical to each other, and the tie rod connecting pipe consists of Made of foamed aluminum alloy, the foamed aluminum alloy is made of aluminum alloy and foaming agent through melting and casting, and the aluminum alloy includes the following components in mass percentage: 0.1-0.3% Si, 2.0-2.6% Cu, 0.3-0.6% Mn, 1.2-1.6% Mg, 0-0.04% Cr, 2.7-3.6% Zn, 0.07-0.15% Ti, 0.15-0.25Zr, 0.3-0.55% Ag, 0-0.25Fe, 3.5-6.3% AlN, 0.03-0.2% RE, the balance is Al.

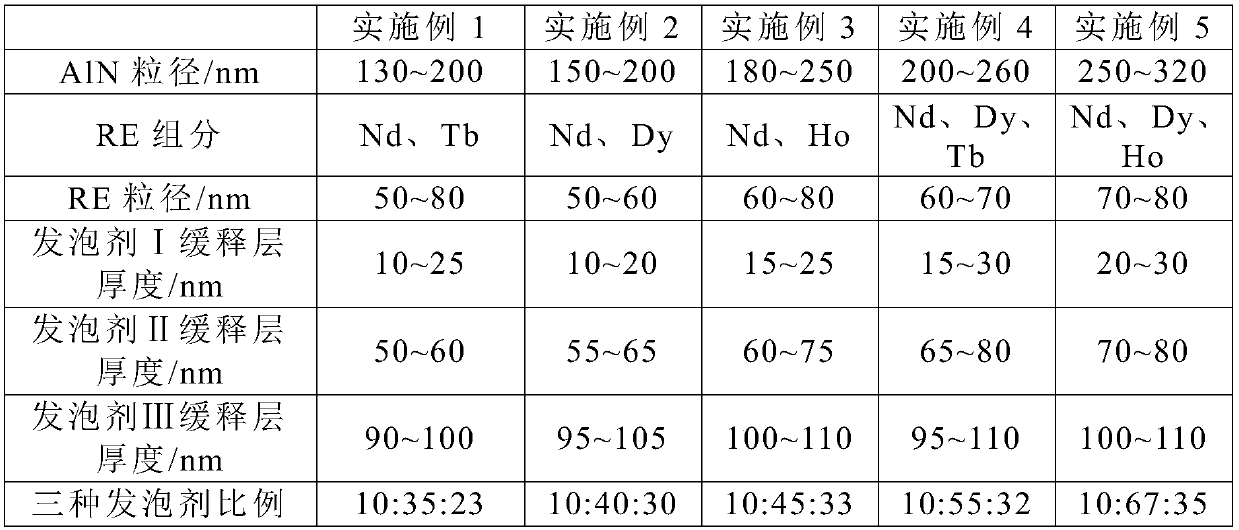

[0035] The particle diameter of AlN is 130-320 nm.

[0036] RE is a nano-powder with a particle size of 50-80 nm mixed with one or more of Nd, Tb, Dy, and Ho.

[0037] The foaming agent is TiH coated with a slow-release layer on the surface 2 , the composition of the sustained release layer...

Embodiment 6

[0044] The preparation method of the tie rod ball joint assembly for lightweight automobiles in this embodiment includes the following steps,

[0045] (1), prepare raw material according to the raw material in embodiment 3 and proportioning, adopt the method for magnetron sputtering in TiH 2 The surface of the particles is coated with a slow-release layer;

[0046] (2) Heat the aluminum alloy to 730°C to melt it into a molten metal, then cool it down to 660°C, add a foaming agent with a mass of 1.5% of the molten metal, stir at 500rmp for 5.5min, pour it, and cool it to obtain a tie rod Connecting pipe prefabricated;

[0047] (3) Heat, heat, heat, and foam the tie rod connecting pipe preform, first raise the temperature to 430°C, hold it for 8 minutes, then raise the temperature to 520°C, hold it for 12 minutes, then raise the temperature to 630°C, hold it for 3 minutes, and heat it during the foaming process Apply a gradually decreasing pressure of 0 to 250MPa to the tie ro...

Embodiment 7

[0049] The preparation method of the tie rod ball joint assembly for lightweight automobiles in this embodiment includes the following steps,

[0050] (1), prepare raw material according to the raw material in embodiment 3 and proportioning, adopt the method for magnetron sputtering in TiH 2 The surface of the particles is coated with a slow-release layer;

[0051] (2) Heat the aluminum alloy to 735°C to smelt it into a molten metal, then cool it down to 670°C, add a foaming agent with a mass of 2.0% of the molten metal, stir at 550rmp for 4 minutes, pour, and cool to obtain a tie rod connection Tube preforms;

[0052] (3) Heat, heat, heat, and foam the tie rod connecting pipe preform, first raise the temperature to 440°C, hold it for 7 minutes, then raise the temperature to 540°C, hold it for 10 minutes, then raise the temperature to 640°C, hold it for 4 minutes, and heat, heat, heat, and foam Apply a gradually decreasing pressure of 0 to 250MPa to the tie rod connecting pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com