Flexible device and its preparation method

A technology of flexible devices and positive active materials, applied in the field of flexible devices, can solve the problems of easy fatigue, decreased bonding strength, and great difficulty, and achieve the effect of increasing the contact area, increasing the bonding strength, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

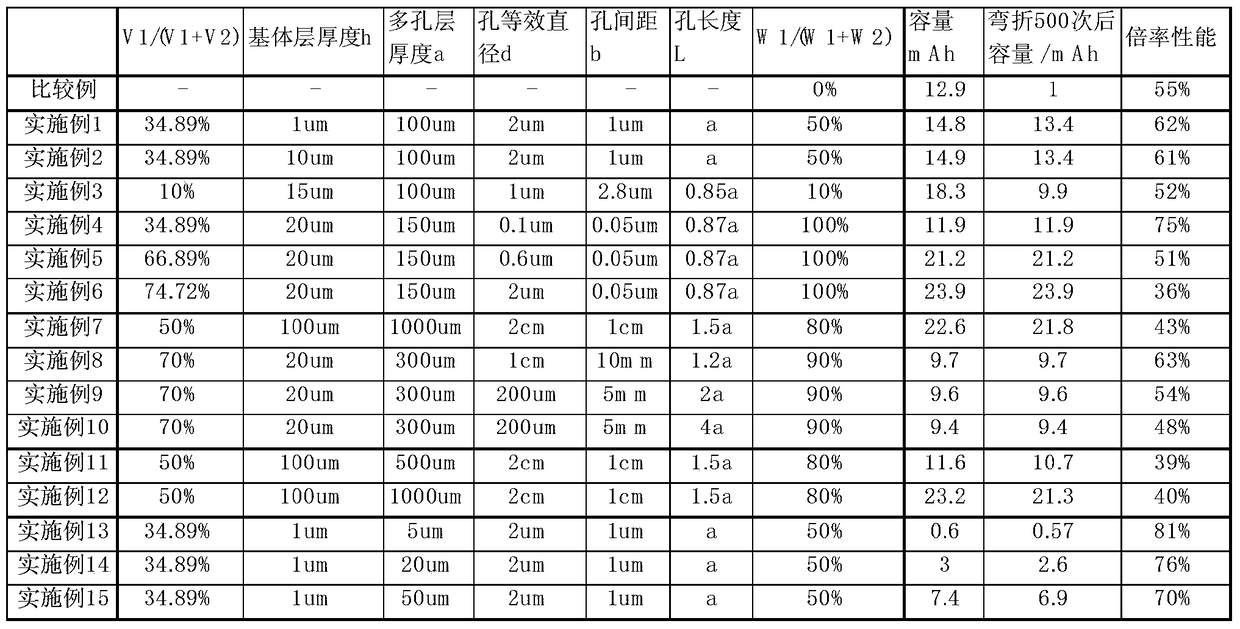

Examples

Embodiment 1

[0037] Preparation of porous current collector: choose an aluminum foil with a thickness of 1 μm as the base layer; select an aluminum foil with a thickness of 100 μm, and then use laser drilling to punch holes in the aluminum foil to obtain a circular hole shape and a hole diameter of 2 μm. The hole spacing (the distance between the closest edges of the two holes) is 1 μm, and the hole depth is 100 μm, so as to obtain the porous structure layer of the porous current collector; the above porous structure layer and the collective layer are cut, and then the conductive glue is used The porous structure layer is bonded on the substrate layer to obtain a porous current collector for use;

[0038] Positive electrode sheet preparation: Sulfur-porous carbon is used as the positive electrode active material (the loading capacity of sulfur is 70%), PVDF is used as the binder, Supper-P is used as the conductive agent (the mass ratio of the three is 94:3:3), and NMP is Solvent configurat...

Embodiment 2

[0041] The difference from Example 1 is that it includes the following steps:

[0042] Preparation of porous current collector: choose an aluminum foil with a thickness of 10 μm as the base layer.

[0043] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0045] The difference from Example 1 is that it includes the following steps:

[0046] Preparation of porous current collector: choose an aluminum foil with a thickness of 15 μm as the base layer; select an aluminum foil with a thickness of 100 μm, and then use laser drilling to punch holes in the aluminum foil to obtain a circular hole shape and a hole diameter of 1 μm. The hole spacing (the distance between the closest edges of the two holes) is 2.8 μm, and the hole depth is 100 μm, so as to obtain the porous structure layer of the porous current collector; the above porous structure layer and the collective layer are cut, and then the conductive glue is used The slurry porous structure layer is bonded to the substrate layer to obtain a porous current collector for use;

[0047] Positive electrode sheet preparation: Sulfur-porous carbon is used as the positive electrode active material (the loading capacity of sulfur is 70%), PVDF is used as the binder, Supper-P is used as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com