Aquilariae lignum resinatum grease extraction and separation method and equipment

A kind of technology of agarwood and separation method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of long consumption time, low quality, high energy consumption, etc., and achieve the effect of long consumption time, high quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Remove the white wood part of the agarwood trunk that does not have agarwood, and only use the woody part of the agarwood that contains brown-black oil. Dried and pulverized as a raw material.

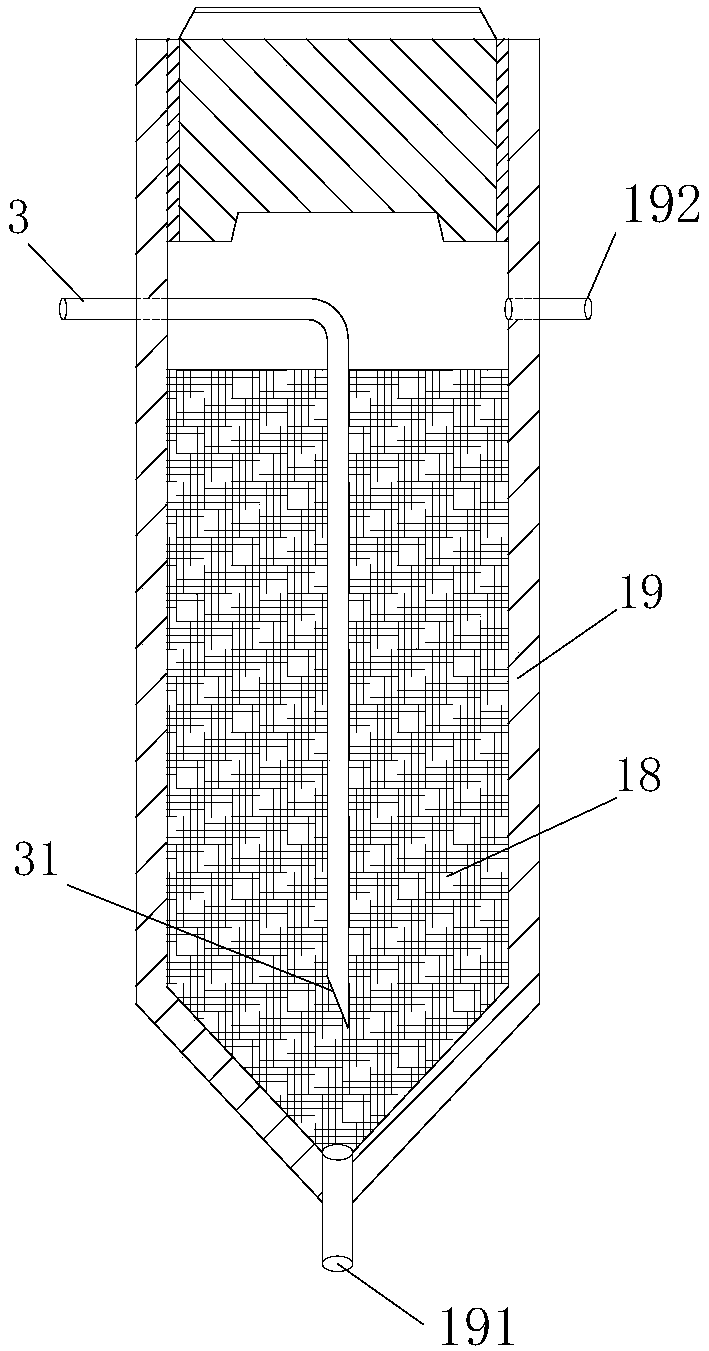

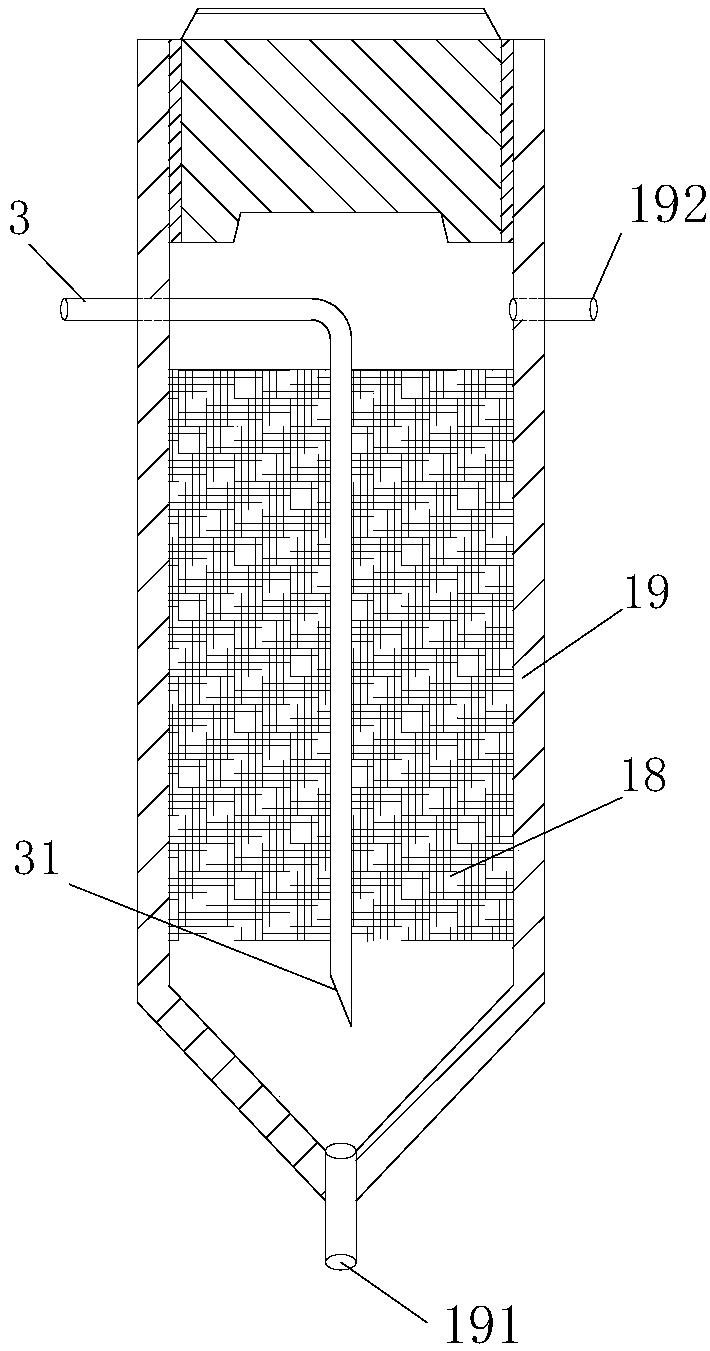

[0039] use figure 1 , figure 2 In the equipment shown, 20kg of Agarwood japonica is put into the extraction kettle 12, the extraction pressure is 28MPa; the extraction temperature is 65°C; the extraction time is 3h; the flow rate of supercritical carbon dioxide is 800L / h. Then enter the separation kettle 13, 14. The first-stage decompression separation pressure is 6MPa, and the first-stage separation temperature is 45°C; Paste, enters mixed extract storage tank 21.

[0040] The mixed extract is heated to 60° C. and subjected to three-stage molecular distillation towers 22, 23, and 24.

[0041] The pressure of the primary molecular distillation is 200 Pa, and the temperature of the primary molecular distillation is 80° C. to obtain the primary light component and the primary ...

Embodiment 2

[0047] Remove the white wood part of the agarwood trunk that does not have agarwood, and only use the woody part of the agarwood that contains brown-black oil. Dried and pulverized as a raw material.

[0048] Put 10kg of Agarwood japonica into the extraction kettle, the extraction pressure is 26MPa; the extraction temperature is 60°C; the extraction time is 2.5h; the supercritical carbon dioxide flow rate is 400L / h. The pressure of the first-stage decompression separation is 5MPa, the temperature of the first-stage separation is 40°C; the pressure of the second-stage decompression separation is 4MPa, and the temperature of the second-stage separation is 35°C, and a mixed extract containing agarwood and jiexiang is obtained.

[0049] The mixed extract is heated to 60°C, and molecular distillation is carried out. The pressure of the primary molecular distillation is 100 Pa, and the temperature of the primary molecular distillation is 100°C to obtain the primary light component a...

Embodiment 3

[0054] Remove the white wood part of the agarwood trunk that does not have agarwood, and only use the woody part of the agarwood that contains brown-black oil. After drying, it is not pulverized as a raw material.

[0055] Put 5kg of Agarwood japonica into the extraction kettle, the extraction pressure is 27MPa; the extraction temperature is 65°C; the extraction time is 2h; the supercritical carbon dioxide flow rate is 200L / h. The pressure of the first-stage decompression separation is 6MPa, the temperature of the first-stage separation is 40°C; the pressure of the second-stage decompression separation is 4MPa, and the temperature of the second-stage separation is 35°C, and a mixed extract containing agarwood and jiexiang is obtained.

[0056] The mixed extract is heated to 60°C, and molecular distillation is carried out. The pressure of the primary molecular distillation is 300Pa, and the temperature of the primary molecular distillation is 70°C to obtain the primary light co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com