Nanometer zinc oxide material and preparation method thereof

A nano-zinc oxide and zinc source technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of poor economic practicability, long synthesis process time, etc., to achieve easy expansion of industrial production and strengthen solvent effect , The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

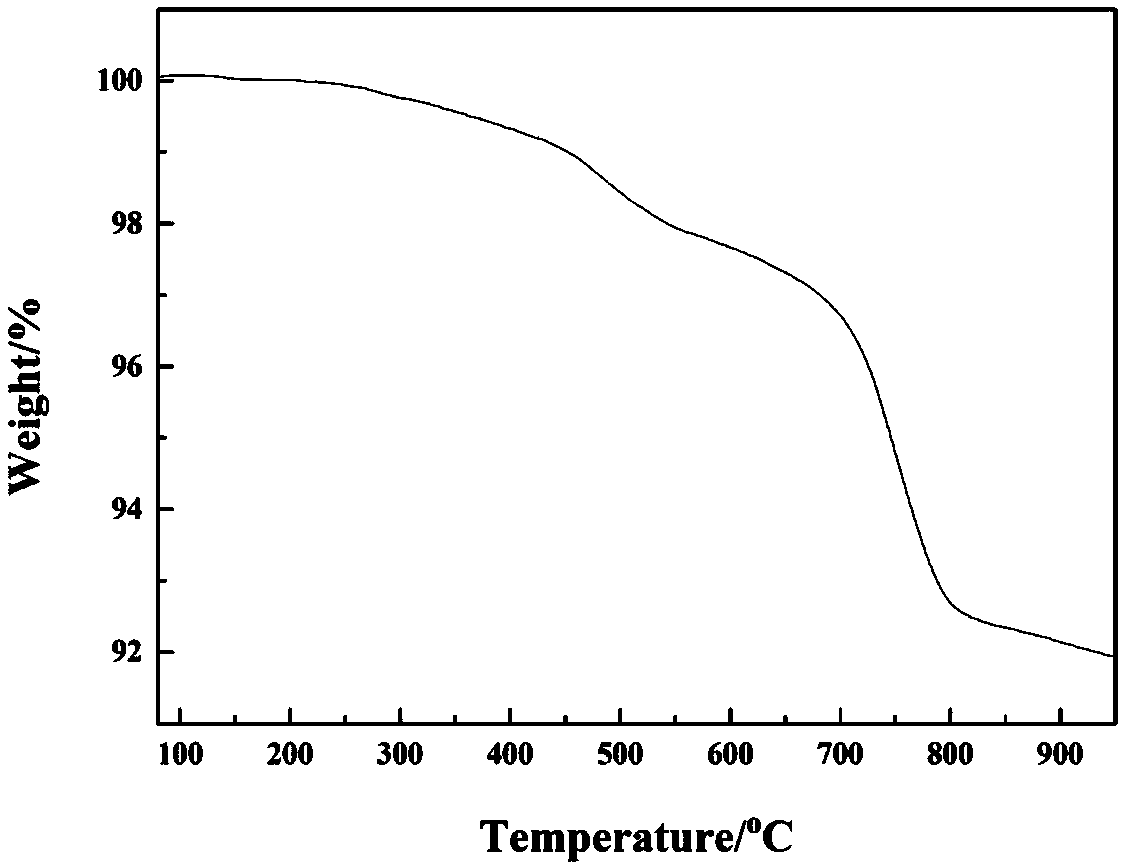

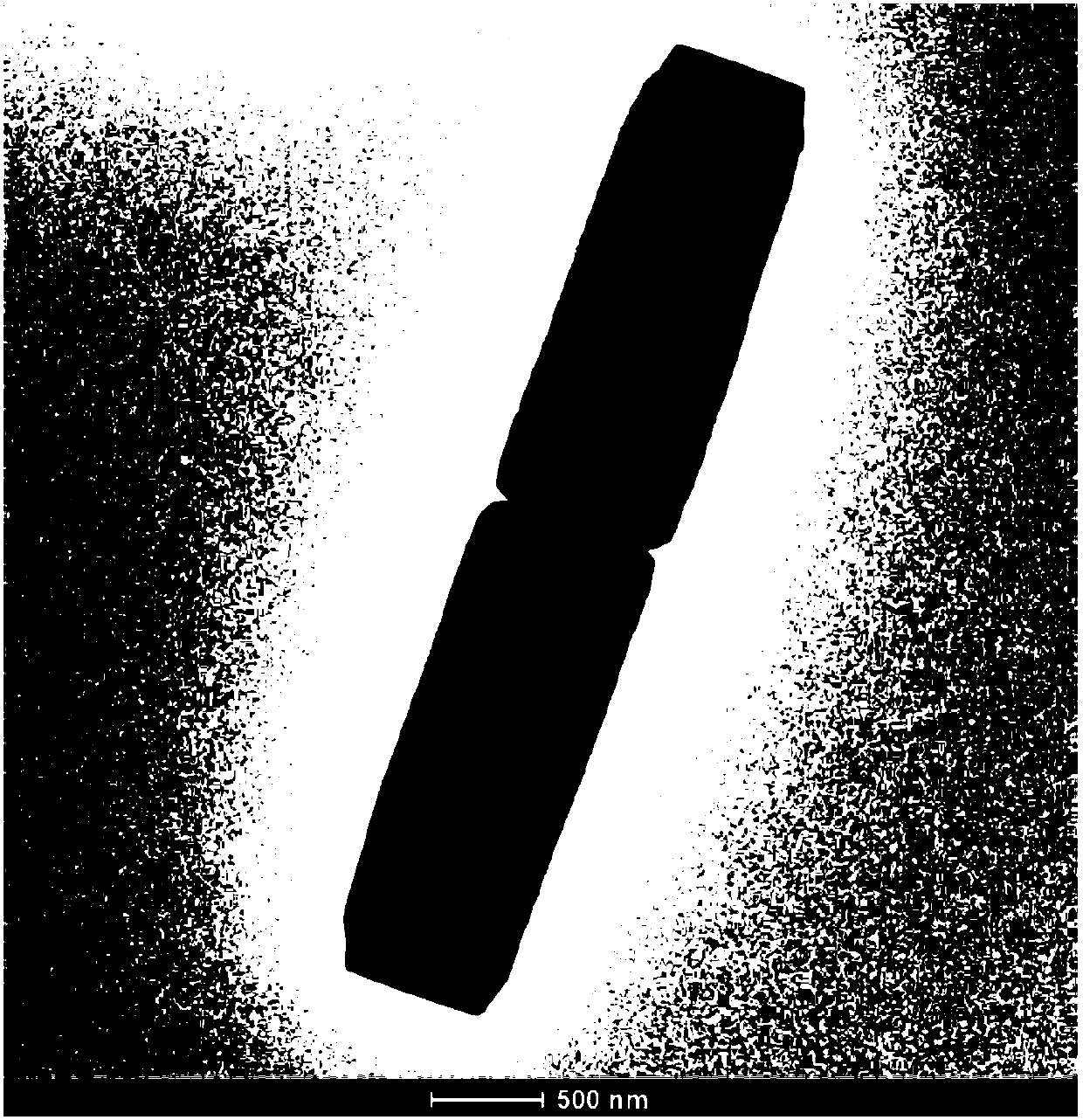

[0034] Weigh 4mmol of zinc nitrate and 8mmol of 2-methylimidazole and dissolve them in 40ml of water, add 0.6g of surfactant polyvinylpyrrolidone, perform ultrasonic vibration and dissolve for 30min, then add them to a 60ml reaction kettle, and put them in the oven In the reaction at 120°C for 12 hours, a white powder was obtained. The powder was washed three times with alcohol and ultrapure water, and then dried at 80°C for one day to obtain a dumbbell-shaped white zinc oxide powder. At the same time, the solvent after the reaction was evaporated in an oven at 60°C to obtain a viscous light yellow ionic liquid.

Embodiment 2

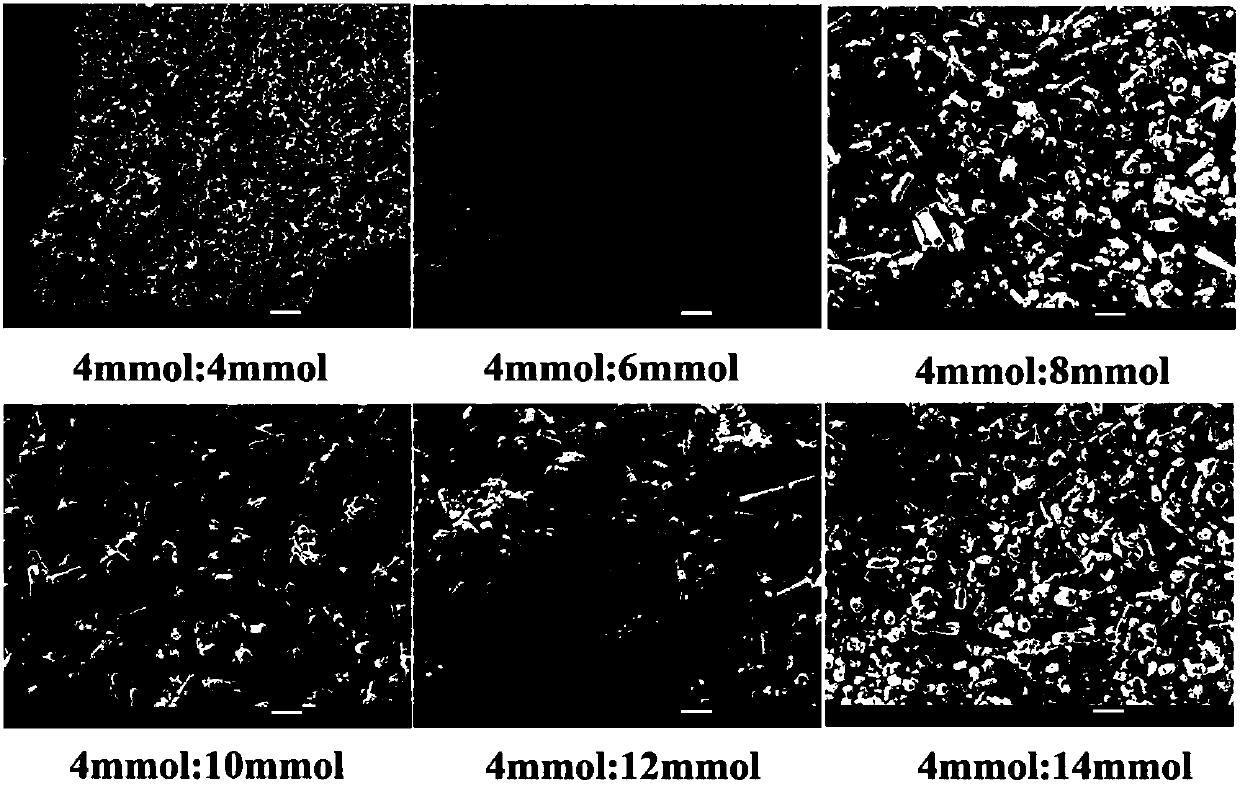

[0036] According to the method of Example 1, the 2-methylimidazole added therein was changed to 4mmol, 6mmol, 8mmol, 10mmol, 12mmol, and 14mmol respectively to obtain a dumbbell-shaped white zinc oxide powder.

Embodiment 3

[0038]According to the method of Example 1, the 0.6g surfactant added therein is changed to tetradecyltrimethylammonium bromide, hexadecyltrimethylammonium bromide, sodium dodecylsulfonate to obtain white oxide zinc powder. Among them, hexadecyltrimethylammonium bromide is zinc oxide with dumbbell shape like polyvinylpyrrolidone, while tetradecyltrimethylammonium bromide is zinc oxide with fluffy dumbbell shape. Sodium sulfonate is a zinc oxide material with a spherical shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com