Laser high-speed scanning and welding system based on galvanometer for battery box, and working method

A high-speed scanning and welding system technology, applied in the field of production and manufacturing, can solve the problems that the one-time pass rate of workpiece welding in processing efficiency is difficult to meet high-quality and efficient production requirements, and takes a long time to improve accuracy and welding quality. The effect of high speed and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

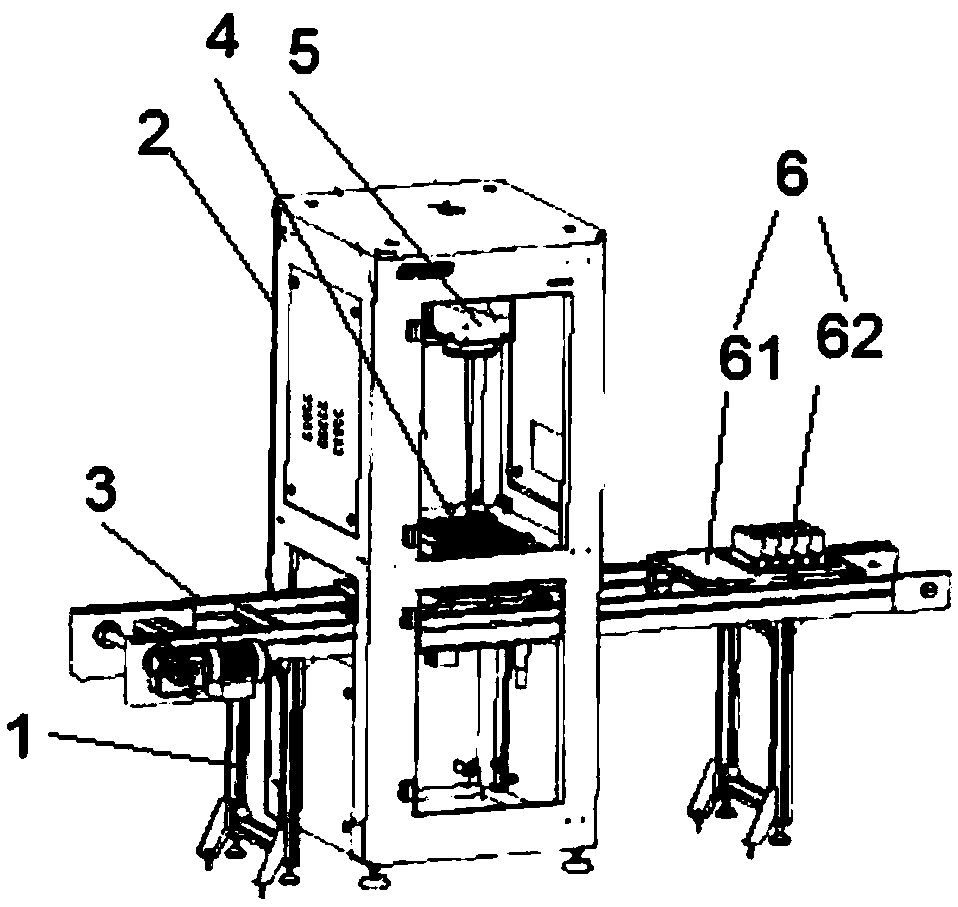

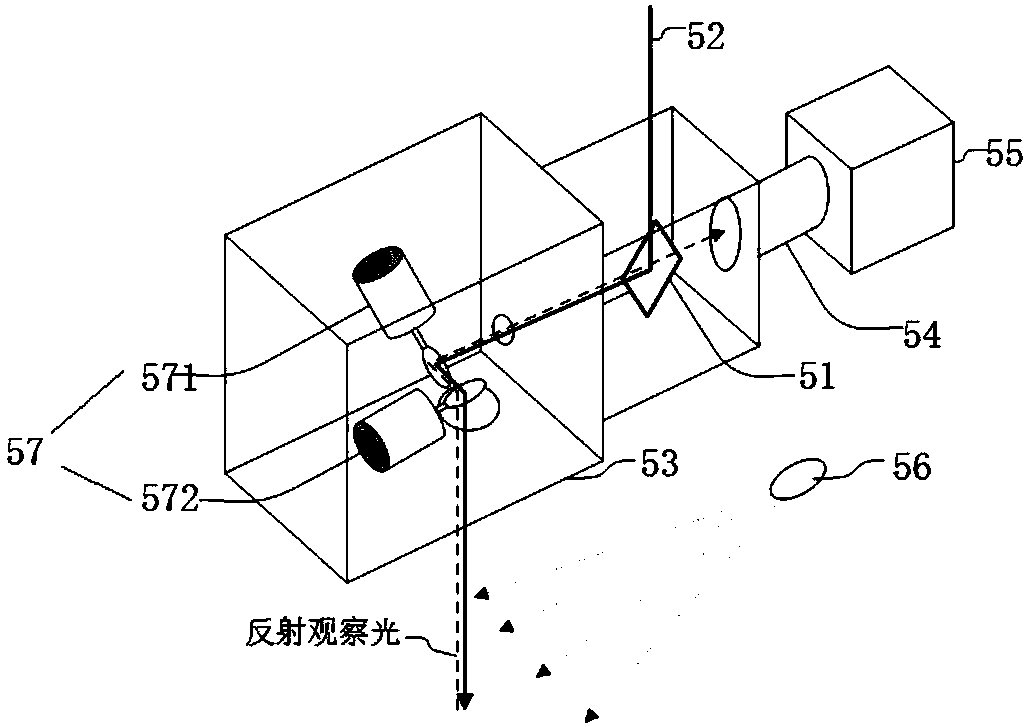

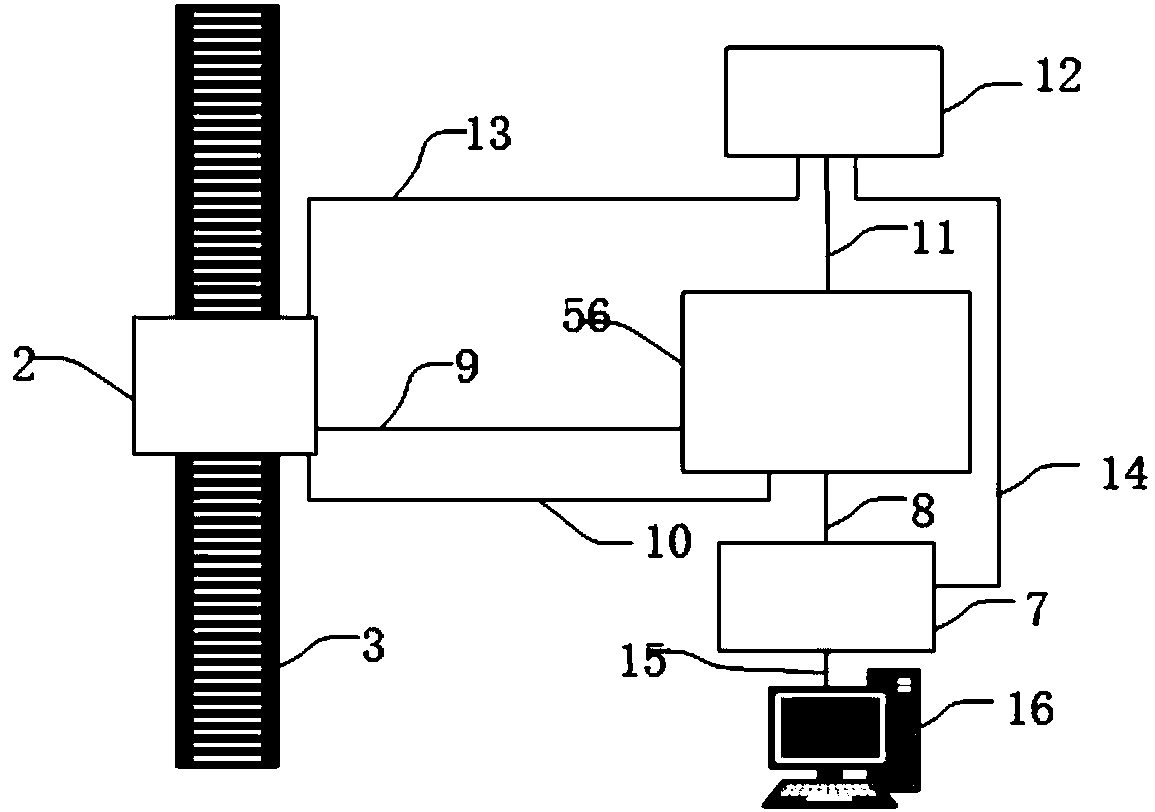

[0041] As shown in the figure, a galvanometer-based battery box laser high-speed scanning welding system includes: a frame 1 and a laser welding protection cabin 2, and the frame 1 is provided with a transportation line 3 for workpiece transportation, and the laser The welding protection cabin 2 is arranged on the transportation line 3, and the laser welding protection cabin 2 is provided with a group of fixtures 4 and a long-distance laser welding plane 5 based on a vibrating mirror. The transportation line 3 is provided with a conveyor for transporting workpieces Mechanism 6, the group fixture 4 is set on the conveying mechanism 6, the long-distance laser welding plane 5 is set on the top of the laser welding protective cabin 2, and the transportation line 3, the group fixture 4, the long-distance laser Welding plane 5, pallet and accompanying fixture 6 are all connected with control center.

[0042] The group clamps 4 described in this embodiment exist in groups, which are ...

Embodiment 2

[0049] As shown in the figure, a galvanometer-based battery box laser high-speed scanning welding system includes: a frame 1 and a laser welding protection cabin 2, and the frame 1 is provided with a transportation line 3 for workpiece transportation, and the laser The welding protection cabin 2 is arranged on the transportation line 3, and the laser welding protection cabin 2 is provided with a group of fixtures 4 and a long-distance laser welding plane 5 based on a vibrating mirror. The transportation line 3 is provided with a conveyor for transporting workpieces Mechanism 6, the group fixture 4 is set on the conveying mechanism 6, the long-distance laser welding plane 5 is set on the top of the laser welding protective cabin 2, and the transportation line 3, the group fixture 4, the long-distance laser Welding plane 5, pallet and accompanying fixture 6 are all connected with control center.

[0050] The group clamps 4 described in this embodiment exist in groups, which are ...

Embodiment 3

[0068] As shown in the figure, a galvanometer-based battery box laser high-speed scanning welding system includes: a frame 1 and a laser welding protection cabin 2, and the frame 1 is provided with a transportation line 3 for workpiece transportation, and the laser The welding protection cabin 2 is arranged on the transportation line 3, and the laser welding protection cabin 2 is provided with a group of fixtures 4 and a long-distance laser welding plane 5 based on a vibrating mirror. The transportation line 3 is provided with a conveyor for transporting workpieces Mechanism 6, the group fixture 4 is set on the conveying mechanism 6, the long-distance laser welding plane 5 is set on the top of the laser welding protective cabin 2, and the transportation line 3, the group fixture 4, the long-distance laser Welding plane 5, pallet and accompanying fixture 6 are all connected with control center.

[0069] The group clamps 4 described in this embodiment exist in groups, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com