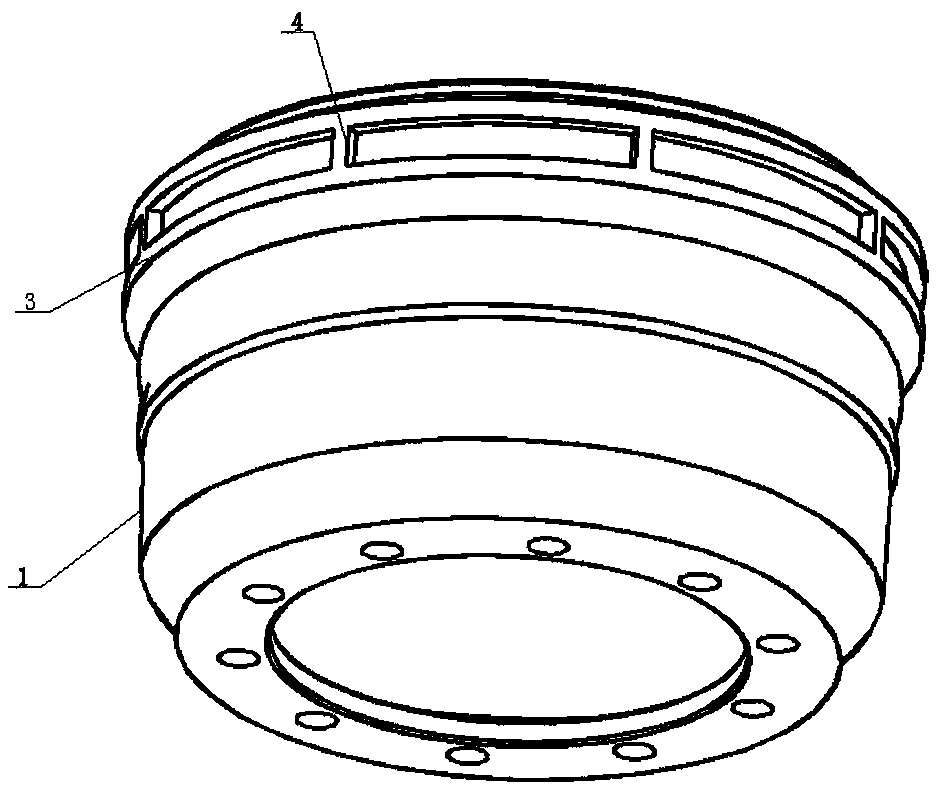

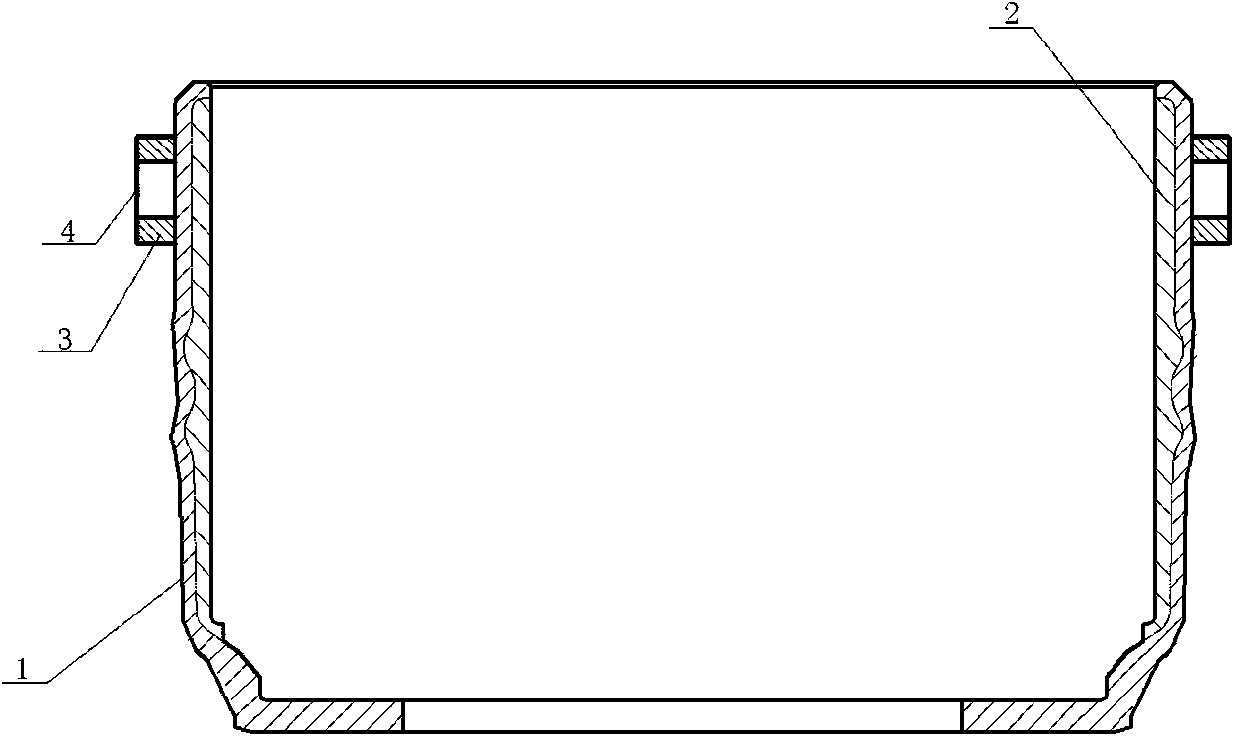

Impeller flange type steel brazing brake drum and preparing method thereof

A technology of brake drum and impeller method, which is applied in the direction of brake drum and slack adjuster, etc., which can solve the problems of brake drum cracking, insufficient strength, and influence on use, and achieve the goal of increasing heat dissipation surface area, improving heat dissipation performance, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method of manufacturing an impeller flange type steel brazing brake drum, comprising the following steps:

[0024] 1) Spin the low-carbon steel plate into the brake drum jacket in separate lanes;

[0025] 2) Assemble the brake drum jacket on the rotating device at a speed of 200r / min, spray the solder on the inner surface of the brake drum jacket, and pour molten iron (liquid metal) into the inner surface of the brake drum jacket The feeder is inserted into the outer casing of the brake drum, and the molten iron can be laid and injected). The material and molten iron form alloy cast iron on the inner surface of the brake drum jacket, and then cooled to room temperature; the brazing material is made by mixing anhydrous sodium borate, copper powder, and ferrosilicon powder in an amount ratio of 2:2:1;

[0026] 3) Set the double-layer flanges on the outer circumference of the brake drum casing and weld them; there are reinforcing ribs between the double-layer flanges. ...

Embodiment 2

[0029] A method of manufacturing an impeller flange type steel brazing brake drum, comprising the following steps:

[0030] 1) Spin the low-carbon steel plate into the brake drum jacket in separate lanes;

[0031] 2) Assemble the brake drum jacket on the rotating device at a speed of 300r / min, spray the solder on the inner surface of the brake drum jacket, and pour molten iron (liquid metal) into the inner surface of the brake drum jacket The feeder is inserted into the outer casing of the brake drum, and the molten iron can be laid and injected), the temperature of the molten iron is 1360°C, and the inner surface area of the outer casing of the brake drum is 0.3㎡, the amount of brazing filler metal and molten iron is 70g and 25kg respectively. The molten iron forms an alloy cast iron on the inner surface of the brake drum jacket, and then cools to room temperature; the brazing filler metal is made by mixing anhydrous sodium borate, copper powder, and ferrosilicon powder in ...

Embodiment 3

[0035] A method of manufacturing an impeller flange type steel brazing brake drum, comprising the following steps:

[0036] 1) Spin the low-carbon steel plate into the brake drum jacket in separate lanes;

[0037] 2) Assemble the brake drum jacket on the rotating device at a speed of 250r / min, spray the solder on the inner surface of the brake drum jacket, and pour molten iron (liquid metal) into the inner surface of the brake drum jacket The feeder is inserted into the outer casing of the brake drum, and the molten iron can be laid and injected), the temperature of the molten iron is 1350°C, and the inner surface area of the outer casing of the brake drum is 0.4㎡, the amount of brazing filler metal and molten iron is 60g and 30kg respectively, and the brazing filler metal and The molten iron forms an alloy cast iron on the inner surface of the brake drum jacket, and then cools to room temperature; the brazing filler metal is made by mixing anhydrous sodium borate, copper po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com