Customized bone-like trabecular structure knee joint prosthesis and manufacturing method

A knee joint prosthesis, trabecular structure technology, applied in knee joint, prosthesis, elbow joint, etc., can solve the problems of increasing patient burden, increasing production cost, increasing product weight, etc., to avoid bone resorption and prosthesis loosening , The effect of reducing the production cost and reducing the weight of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

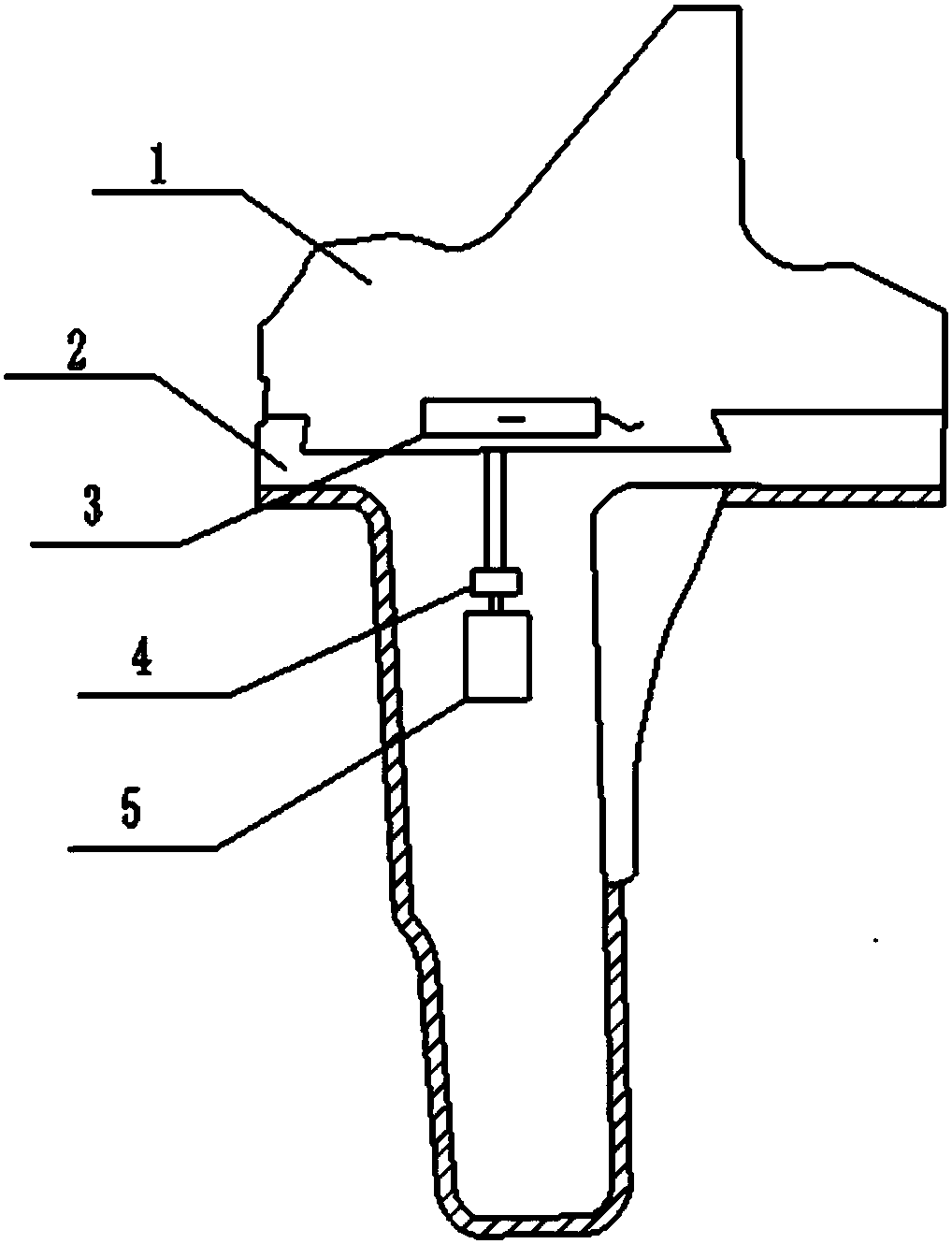

Embodiment 1

[0034] As shown in the figure, this embodiment provides a knee joint prosthesis with a personalized bone-like trabecular structure and adaptive to the patient's living habits; Physiological curvature, while reducing stress shielding, avoiding bone resorption and prosthetic loosening, and also facilitating bone ingrowth in the later stage; in order to achieve the purpose of adapting to the patient's living habits, an induction sensor is specially installed on the tibial pad component. The device is used to sense the pressure between the femoral condyle and the tibial tray. The adjustment mechanism is installed on the tibial tray component to adjust the position of the femoral condyle and the tibial tray. The control mechanism, the sensing mechanism and the adjustment mechanism are all connected with the control mechanism. connected, the control mechanism receives the signal transmitted by the sensing mechanism to adjust the positions of the femoral condyle and the tibial tray. ...

Embodiment 2

[0042] The 3D printed personalized bone-like trabecular structure knee joint prosthesis provided in this embodiment is all 3D printed with PEEK material; the part of the prosthesis in contact with the tibial medullary cavity is a bone trabecular grid structure.

[0043] The manufacturing method of the customized personalized 3D printing 3D printing personalized bone-like trabecular structure knee prosthesis provided in this embodiment specifically includes the following steps:

[0044] S01, obtain medical image data: the patient undergoes knee joint CT examination, obtains all bone data in the operation area, and saves it in a format recognizable by medical images;

[0045] S02, Obtain the medical imaging parameters of the knee joint: Import all the bone models of the surgical area into the medical software Mimis18.0, reversely establish the three-dimensional model of the knee joint in the surgical area, and measure the impact parameters of the surgical area to obtain the anter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com