Socket connector of double-row needle structure and protecting structure thereof

A technology of socket connector and double-row pins, which is applied in the direction of connection, parts of the connection device, and a device to prevent wrong connection, etc., to achieve the effects of strong practicability, improved stability, and increased times of plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

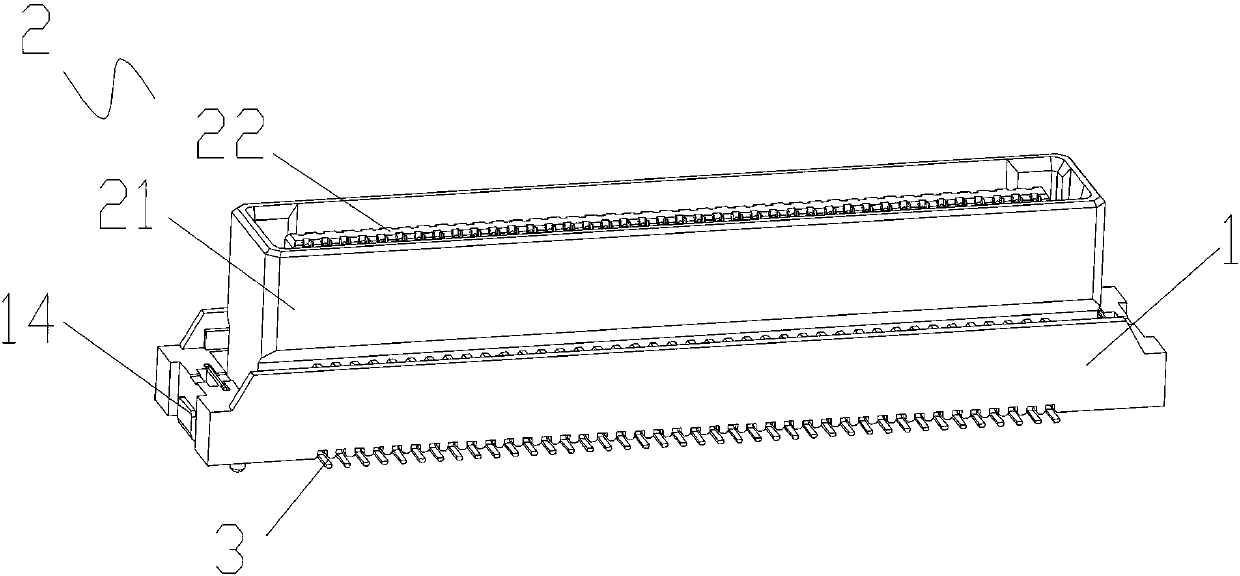

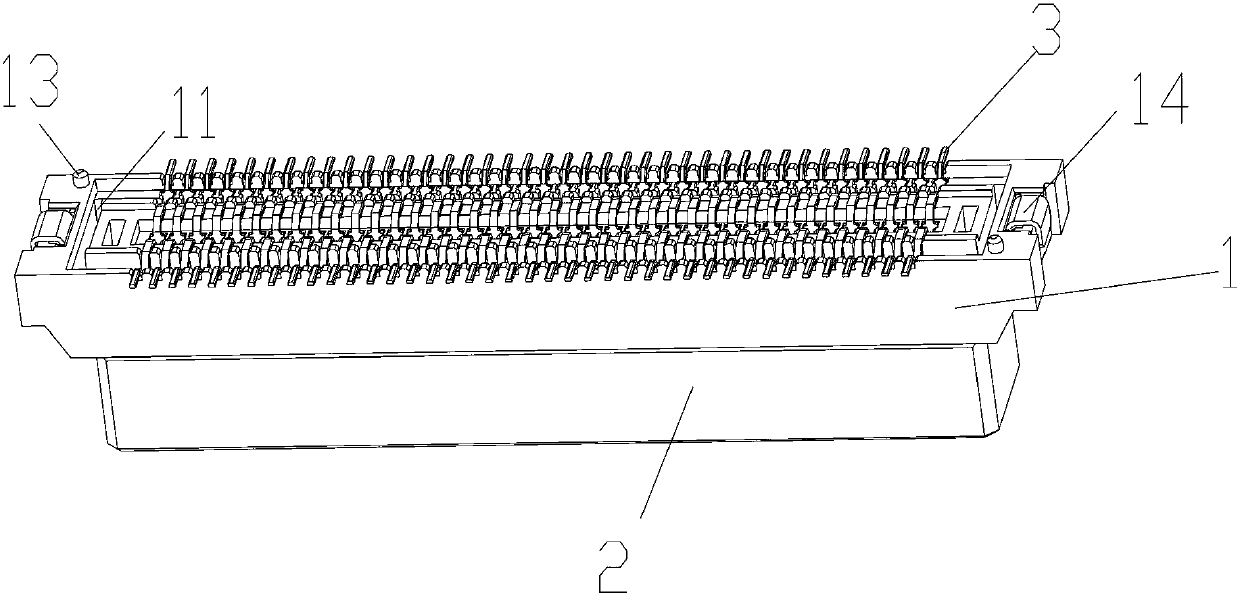

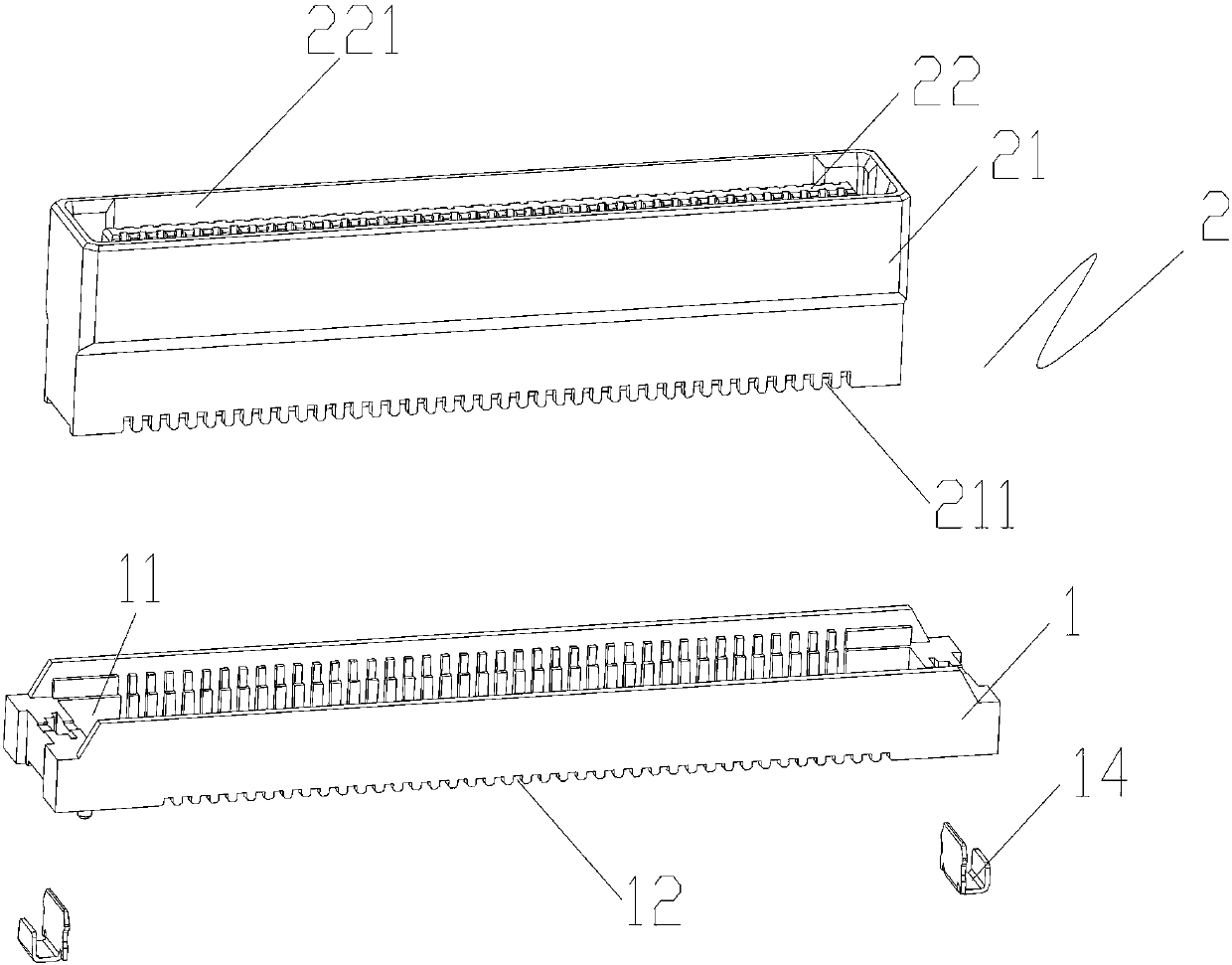

[0024] like Figure 1 to Figure 5 As shown, a socket connector with a double-row pin structure includes a base rubber core 1, a floating rubber core 2 set in the base rubber core 1, and a floating rubber core 2 set between the base rubber core 1 and the floating rubber core 2. Elastic socket terminal 3. The middle part of the base rubber core 1 is provided with a base rubber core opening 11 whose length and width are larger than the floating rubber core 2; the floating rubber core 2 is arranged in the base rubber core opening 11, and the floating rubber core 2 is connected to the base rubber core 1 through the elastic socket terminal 3.

[0025] The floating rubber core 2 includes a floating rubber core shell 21 and a rubber core tongue 22 arranged in the floating rubber core shell 21 and forming an inner recessed socket slot between the floating rubber core shells. Wherein, the floating rubber core shell 21 and the rubber core tongue 22 are integrally structured. The two s...

Embodiment 2

[0034] The invention also discloses a socket connector protection structure with a double-row needle structure, such as Image 6 As shown, the protection structure can effectively prevent dust and foreign matter from entering the socket connector, thereby achieving the effect of preventing dust and foreign matter, and at the same time, it is convenient for customers to realize mechanical automation in the subsequent production process.

[0035] like Image 6 As shown, a socket connector protection structure with a double-row pin structure is characterized in that it includes the above-mentioned socket connector with a double-row pin structure and a socket cover 4 disposed in the floating rubber core 2 . Wherein, the socket cover and the socket connector are connected by a buckle structure, which is convenient for disassembly.

[0036] The shape and size of the socket cover are matched with the floating rubber core, and a triangular-shaped protrusion is provided on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com