Monolithic Integrated Magnetic Inductive Sensor Based on Surface Acoustic Wave Resonator

A magnetic induction sensor and surface acoustic wave technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of difficult production and processing, low integration of magnetic induction sensors, etc., and achieve the effects of easy production and processing, easy digital acquisition and processing, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

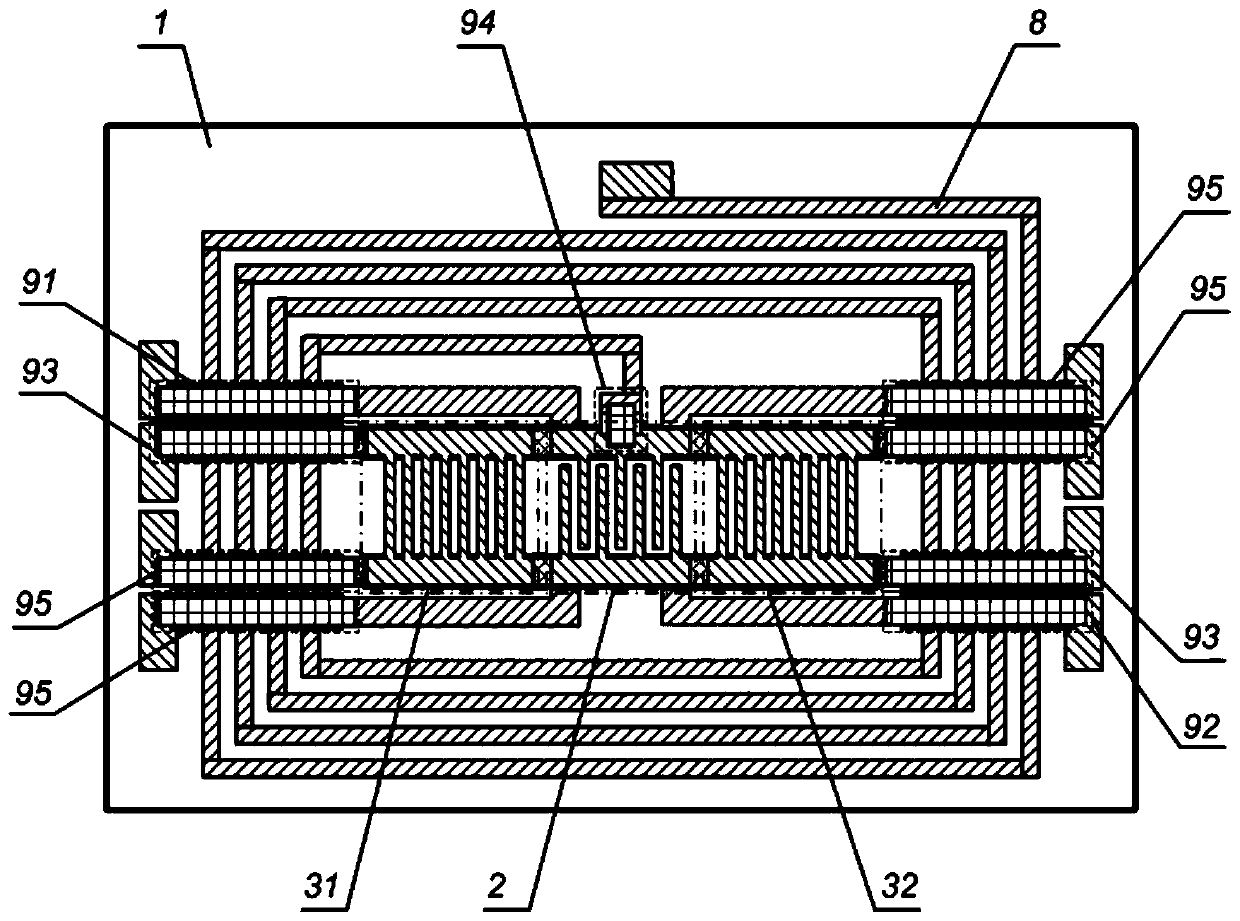

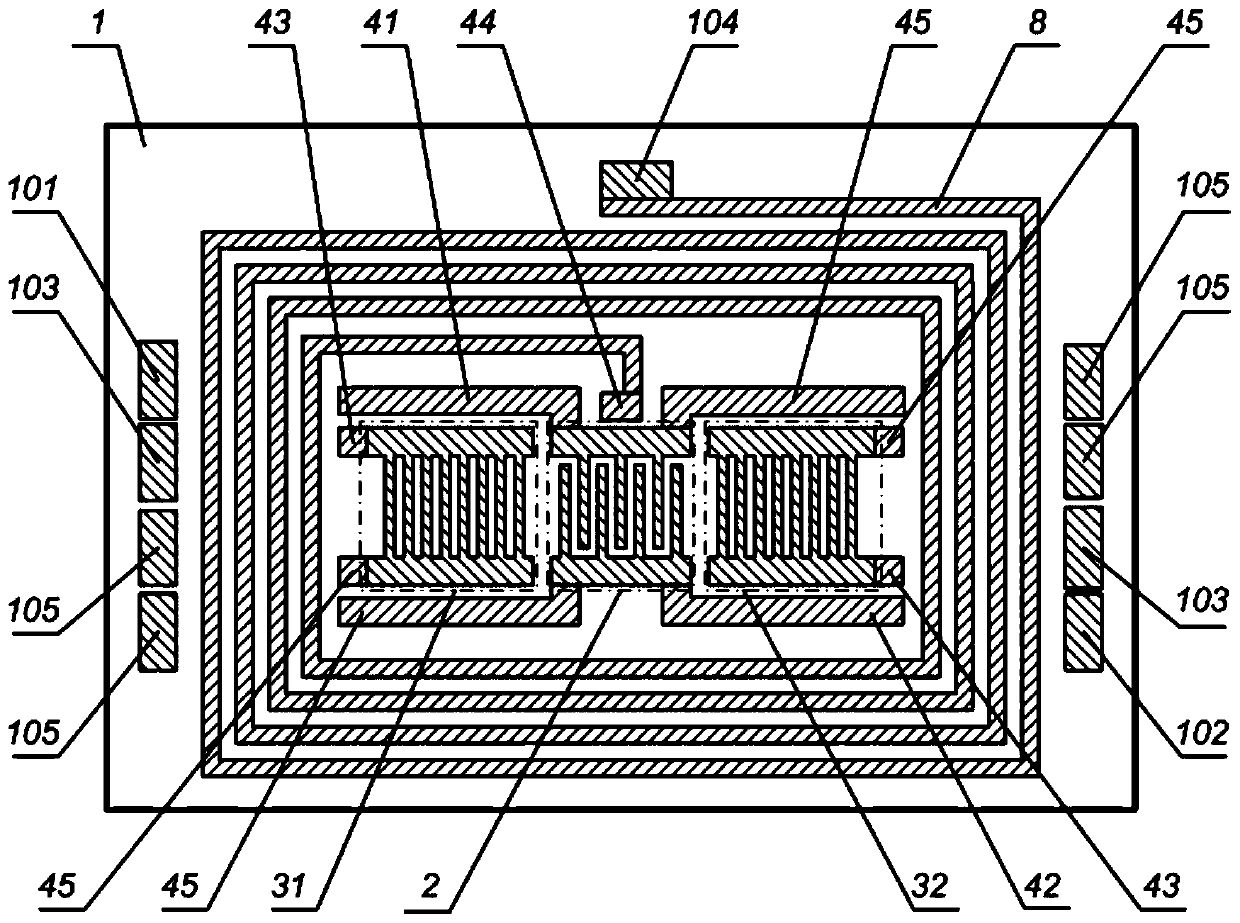

[0032] like figure 1 As shown, the monolithic integrated magnetic induction sensor based on the surface acoustic wave resonator of the present invention comprises a piezoelectric substrate 1, a surface acoustic wave resonator etched on the piezoelectric substrate 1, a plane etched on the piezoelectric substrate 1 The magnetic induction coil 8, the planar magnetic induction coil 8 surrounds the periphery of the surface acoustic wave resonator, and the inner end of the planar magnetic induction coil 8 is connected to the surface acoustic wave resonator through the DC bias electrode 44 and the DC bias bridge 94 successively, Its outer end is connected to the DC bias ground electrode 104 etched on the upper edge of the piezoelectric substrate 1 .

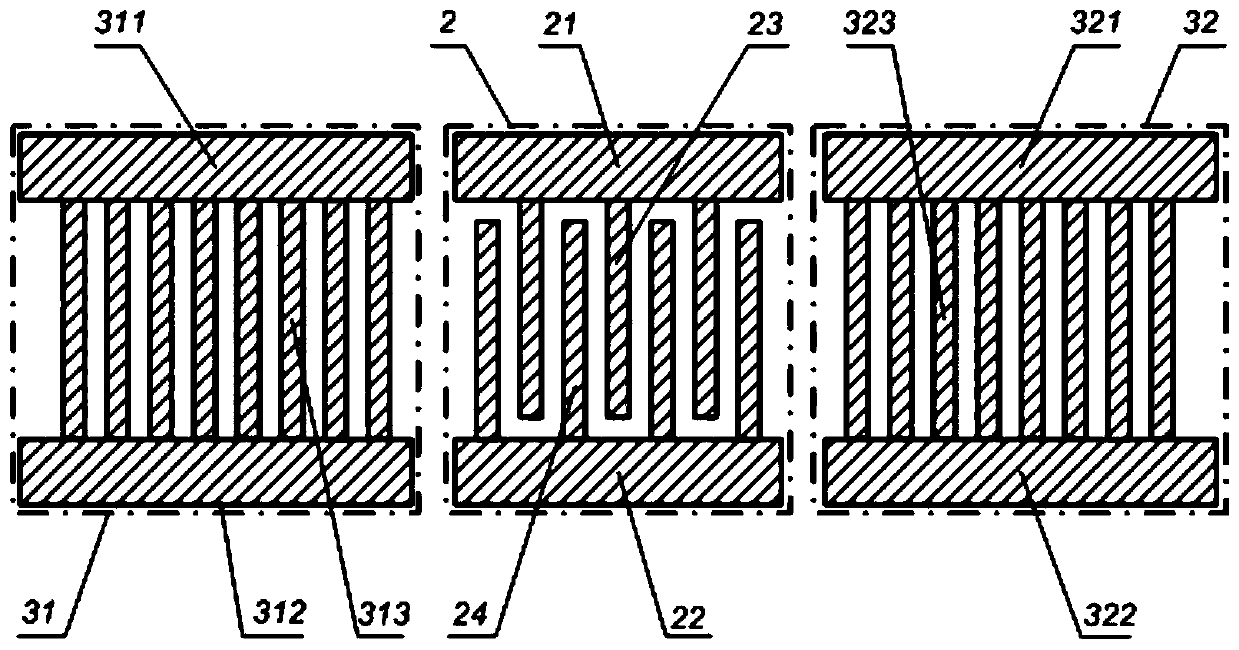

[0033] like figure 2 , 3 , 4, 5,

[0034] The surface acoustic wave resonator includes a metal structure layer, an intermediate dielectric layer and a voltage regulation electrode layer laminated on the piezoelectric substrate 1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com