Rapid and mass spore production method for sweet potato black rot bacteria

A technology for black spot fungus and black spot disease, which is applied in the field of agricultural plant protection, can solve the problems of low efficiency and long time consumption, and achieves the effects of scientific and rapid method, improved spore production and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

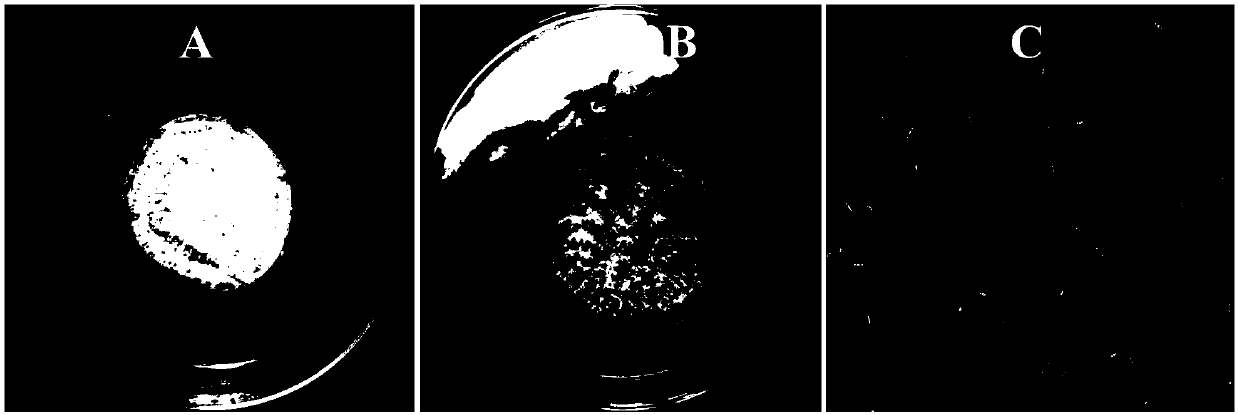

Image

Examples

Embodiment 1

[0025] A kind of method for fast large-scale spore production of sweet potato black spot fungus specifically comprises the following steps:

[0026] 1) Isolation and purification of black spot bacteria: collect black spot diseased potato pieces from sweet potato cellars, and isolate black spot bacteria by tissue separation method; first clean the surface of the potato pieces, then rinse them with running water for about 20 minutes, and remove the diseased potato pieces. Take it out and dry it and put it in an ultra-clean workbench, put the disease-healthy junction of black spot disease into 75% alcohol for surface disinfection, then disinfect it with 0.1% mercuric chloride, clean it with sterilized water, and place it on potato dextrose agar (PDA) plate culture, after separation and purification and Koch's rule validation confirmed to retain the strain;

[0027] 2) Cultivation of black spot bacteria and preparation of spore suspension:

[0028] Control group 1: Use PDA plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com