Rotary pressure welding mechanism used for automatically mounting automobile rear quarter window glass bright molding

A technology for automatic installation and window glass, which is applied in the direction of hand-held tools and manufacturing tools, to avoid damage, improve production efficiency, and solve the effect of optical pole change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to show the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

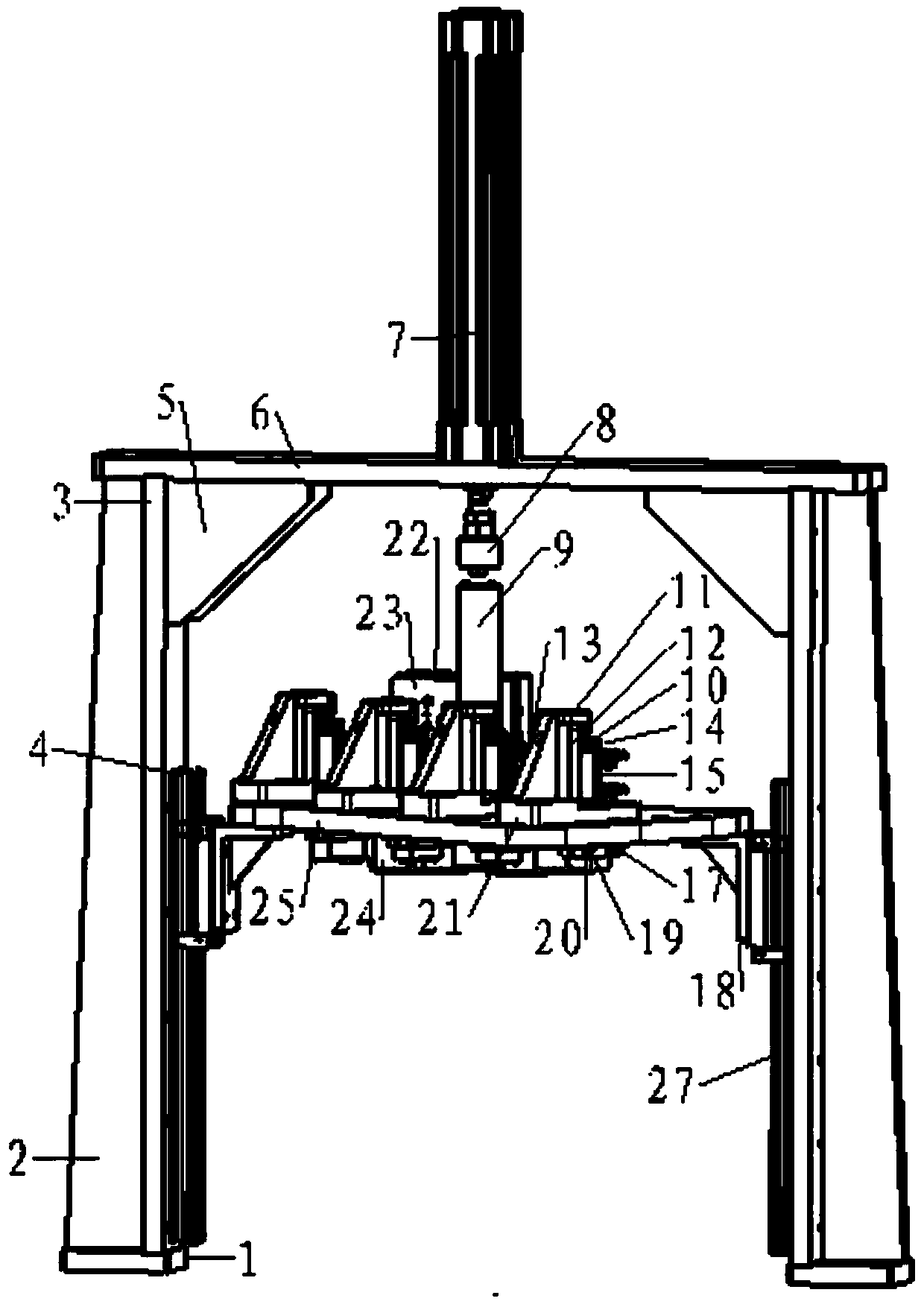

[0027] The rotary crimping mechanism for automatically installing the bright trim strip of the rear triangle window glass of the car of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes gantry support base 1, gantry support vertical plate 3, guide rail 4, gantry beam 6, lifting cylinder 7, floating joint 8, connecting column 9, rotary crimping mechanism, slider fixing plate 18, straight edge mechanism, Main fixed plate 25 and slide block 27,

[0028] The gantry support vertical plate 3 is placed on the gantry support base 1 and is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com