Hollow glass for preventing dew formation and frost formation

A frosting and hollow technology, applied in the direction of coating, etc., can solve problems such as condensation, a layer of fog on the glass surface, and poor light transmission of the glass, so as to achieve scientific and reasonable proportioning, prevent condensation and frost, and prevent condensation and frost. water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

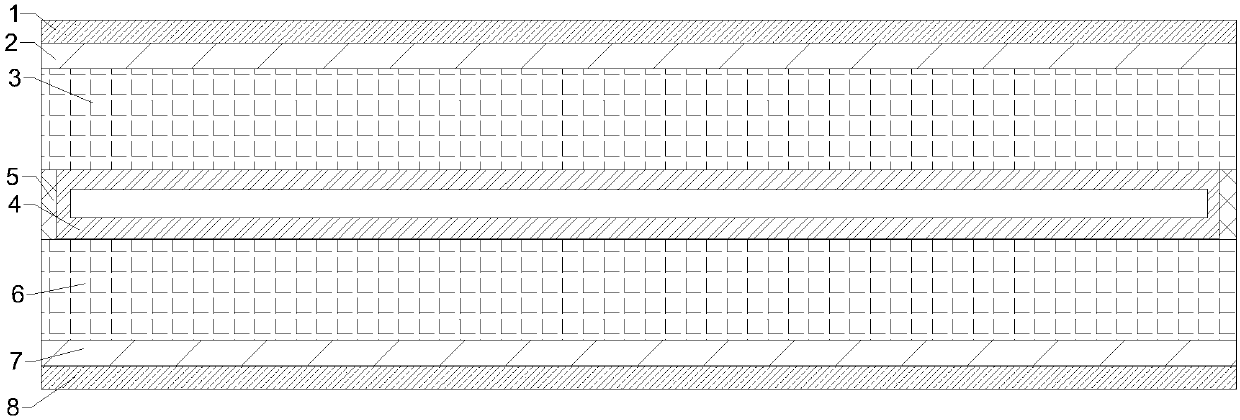

[0019] as attached figure 1 As shown, the present invention discloses a hollow glass for preventing dew and frost, which includes a first glass substrate, a second glass substrate and an aluminum frame, and the first glass substrate and the second glass substrate are arranged in parallel on the On both sides of the aluminum frame, a cavity is formed between the first glass substrate, the second glass substrate and the aluminum frame, the aluminum frame is connected with the first glass substrate and the second glass substrate through a sealant, and the cavity is filled with inert gas;

[0020] The outer surface of the first glass substrate and the outer surface of the second glass substrate are respectively provided with a first hydrophobic film layer and a second hydrophobic film layer, and the first hydrophobic film layer and the second hydrophobic film layer All are prepared from the following raw materials in parts by weight: 30 parts of tetraethyl orthosilicate, 12 parts...

Embodiment 2

[0026] as attached figure 1 As shown, the present invention discloses a hollow glass for preventing dew and frost, which includes a first glass substrate, a second glass substrate and an aluminum frame, and the first glass substrate and the second glass substrate are arranged in parallel on the On both sides of the aluminum frame, a cavity is formed between the first glass substrate, the second glass substrate and the aluminum frame, the aluminum frame is connected with the first glass substrate and the second glass substrate through a sealant, and the cavity is filled with inert gas;

[0027] The outer surface of the first glass substrate and the outer surface of the second glass substrate are respectively provided with a first hydrophobic film layer and a second hydrophobic film layer, and the first hydrophobic film layer and the second hydrophobic film layer All are prepared from the following raw materials in parts by weight: 40 parts of tetraethyl orthosilicate, 10 parts...

Embodiment 3

[0033] as attached figure 1 As shown, the present invention discloses a hollow glass for preventing dew and frost, which includes a first glass substrate, a second glass substrate and an aluminum frame, and the first glass substrate and the second glass substrate are arranged in parallel on the On both sides of the aluminum frame, a cavity is formed between the first glass substrate, the second glass substrate and the aluminum frame, the aluminum frame is connected with the first glass substrate and the second glass substrate through a sealant, and the cavity is filled with inert gas;

[0034] The outer surface of the first glass substrate and the outer surface of the second glass substrate are respectively provided with a first hydrophobic film layer and a second hydrophobic film layer, and the first hydrophobic film layer and the second hydrophobic film layer All are prepared from the following raw materials in parts by weight: 50 parts of tetraethyl orthosilicate, 8 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com