Preparation method of a magnetically ordered mesoporous fe3o4@mcm-48 composite adsorption material

A composite adsorption material and magnetic technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the limitations of the wide application of magnetic mesoporous composite adsorption materials, long preparation period of hydrothermal method, consumption of template agent Large and other problems, to achieve the effect of low cost, low toxicity, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

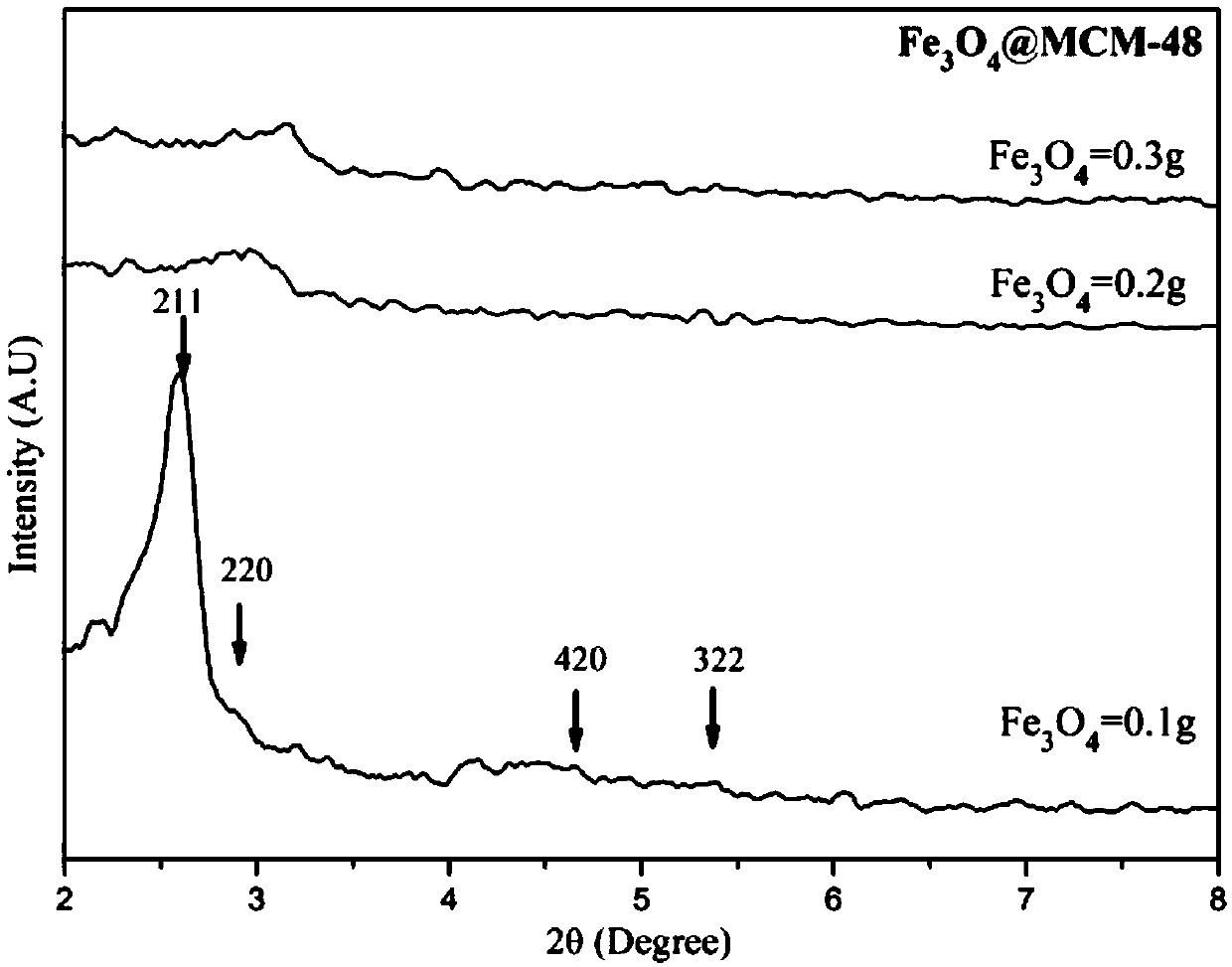

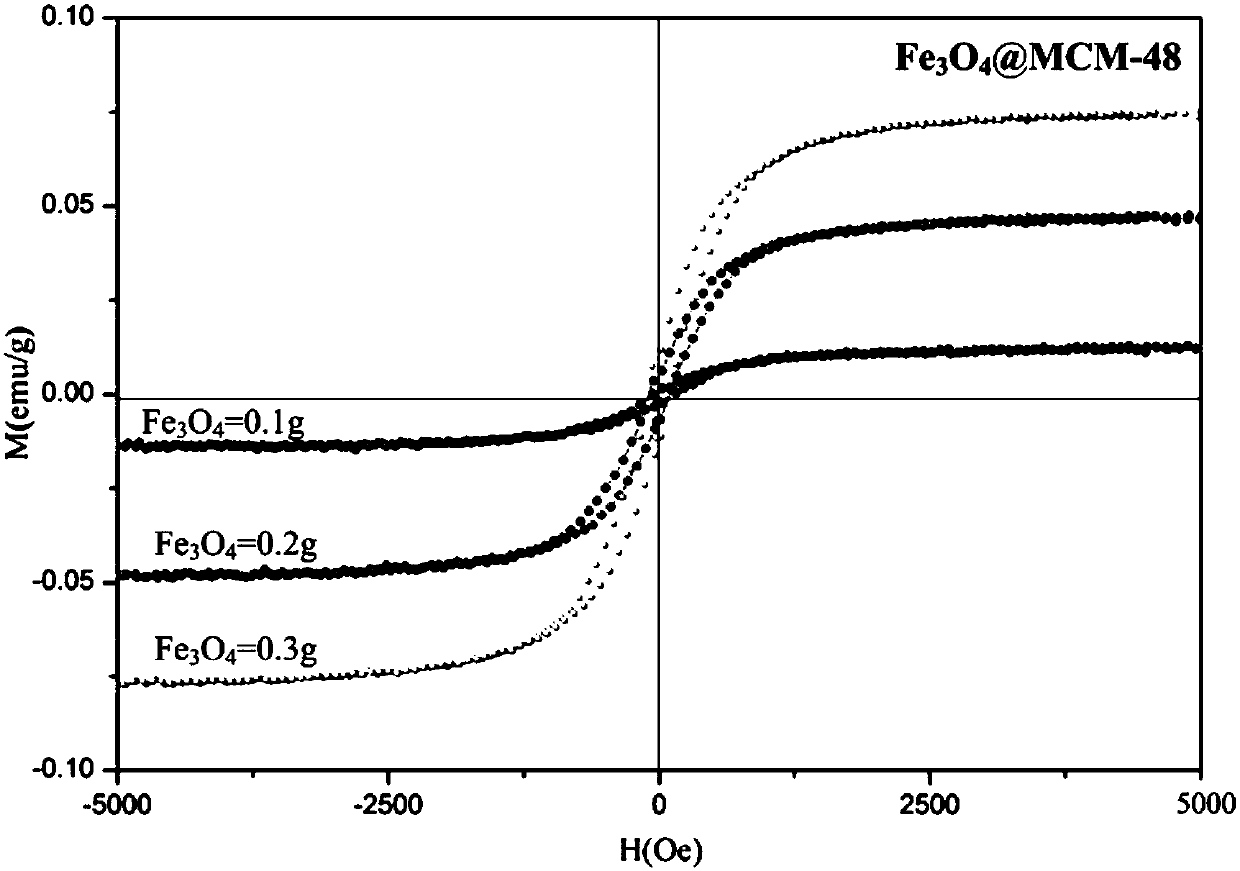

[0050] A magnetically ordered mesoporous Fe provided by the invention 3 o 4 The preparation method of @MCM-48 composite adsorption material comprises the following steps:

[0051] S1, take Fe 3 o 4 Dissolve in chloroform, ultrasonic 10 ~ 20min, to get a mixed solution;

[0052] S2, take the mixed solution obtained in S1 and add it to the aqueous solution containing cetyltrimethylammonium bromide, continue ultrasonic stirring for 3-8 minutes, raise the temperature of the solution to 50-70°C, and then continue to evaporate for 1-3 minutes , a solution of ferrite particles was obtained; the cetyltrimethylammonium bromide used in S2 was compared with the Fe used in S1 3 o 4 The ratio is 0.0005mol:0.05g;

[0053] S3, take the ferrite particle solution obtained in S2 and add it to cetyltrimethylammonium bromide-ethylene glycol-water solution, and stir for 5-15 minutes; then add ammonia water to adjust the pH to 11, then add absolute ethanol, Continue to stir; then add ethyl o...

Embodiment 1

[0057] A magnetically ordered mesoporous Fe 3 o 4 The preparation method of @MCM-48 composite adsorption material, the specific steps are as follows:

[0058] S1, take 0.1g ferrite Fe 3 o 4 Dissolved in 3ml of chloroform, 400W ultrasonic 15min, to obtain a mixed solution; used here is Fe 3 o 4 nanoparticles;

[0059] S2, take half the volume of the mixed solution obtained in S1 and add it to 25ml of 0.8g / 100ml cetyltrimethylammonium bromide (CTAB) aqueous solution (that is, add 0.0005molCTAB), continue 400W ultrasonic stirring for 5min, and The temperature of the solution was raised to 60°C, and then continued to evaporate for 2 minutes to remove the organic chloroform. At this time, a surfactant-stabilized ferrite particle solution was obtained, and the ferrite particles showed hydrophilicity;

[0060] S3, take the ferrite particle solution obtained in S2 and add it to 62g of cetyltrimethylammonium bromide-ethylene glycol-water solution, stir for 10min; then add ammonia...

Embodiment 2

[0064] A magnetically ordered mesoporous Fe 3 o 4 The preparation method of @MCM-48 composite adsorption material, the specific steps are the same as in Example 1, the only difference is the Fe used in S1 3 o 4 The mass is 0.2g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com