A steel slag filter material for sponge city construction and preparation method thereof

A sponge city and steel slag technology, applied in the field of solid waste resource utilization, to achieve the effects of controlling emptying time, saving social building material resources, and meeting water quality control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

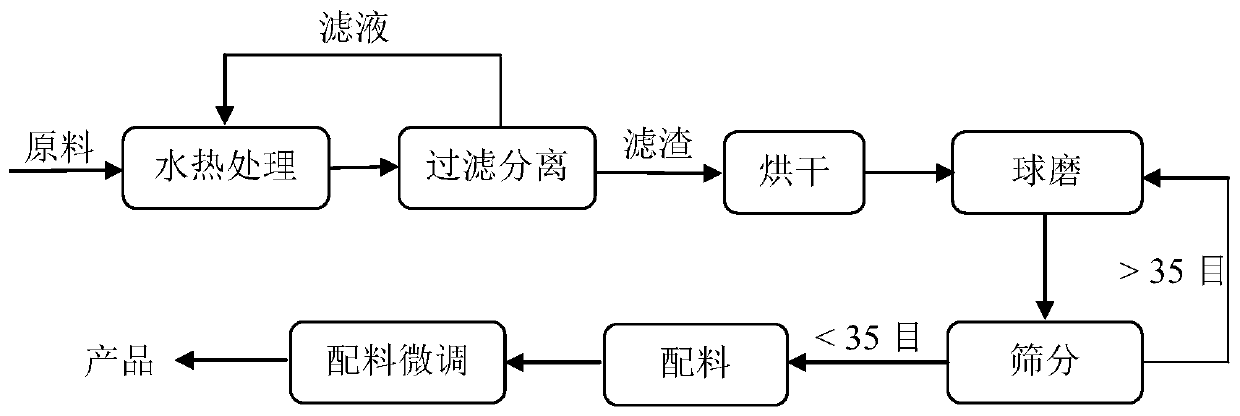

[0037] A steel slag filter material used for sponge city construction, its process flow chart is shown in figure 1 , its preparation method comprises the following steps:

[0038] 1) The steel slag used as raw material is the converter steel slag treated by the hot pouring method. The converter steel slag is crushed, iron-selected and sieved to collect the part less than 5mm, and then add water according to the liquid-solid ratio (mass ratio) of 1:3 and place it in a high-pressure reactor inside, heated to 150°C for 12 hours for hydrothermal treatment, and then naturally cooled to room temperature;

[0039]2) Filter the reaction product obtained in the reaction kettle, and reuse the filtrate for the next hydrothermal treatment, and dry the obtained solid product at 105° C. for 4 hours, and set aside;

[0040] 3) using a ball mill to perform ball milling on the dried solid product, and the ball milling time is 8 hours;

[0041] 4) Sieve the steel slag after ball milling, and ...

Embodiment 2

[0051] A kind of steel slag filter material that is used for sponge city construction, its preparation method comprises the following steps:

[0052] 1) The steel slag used as the raw material is the converter steel slag treated by the drum method. The converter steel slag is crushed, iron-selected and sieved to collect the part less than 5mm, and then add water according to the liquid-solid ratio (mass ratio) of 1:3 and put it in the high-pressure reactor , heated to 180 ° C for 10 h for hydrothermal treatment, and then naturally cooled to room temperature;

[0053] 2) Filter the reaction product obtained in the reaction kettle, and reuse the filtrate for the next hydrothermal treatment, and dry the obtained solid product at 105° C. for 4 hours, and set aside;

[0054] 3) using a ball mill to perform ball milling on the dried solid product, and the ball milling time is 6 hours;

[0055] 4) Sieve the steel slag after ball milling, and separate four steel slags larger than 35 ...

Embodiment 3

[0065] A kind of steel slag filter material that is used for sponge city construction, its preparation method comprises the following steps:

[0066] 1) The steel slag used as the raw material is the converter steel slag treated by the drum method. The converter steel slag is crushed, iron-selected and sieved to collect the part less than 5mm, and then add water according to the liquid-solid ratio (mass ratio) of 1:3 and put it in the high-pressure reactor , heated to 160 ° C for 16 hours for hydrothermal treatment, and then naturally cooled to room temperature;

[0067] 2) Filter the reaction product obtained in the reaction kettle, and reuse the filtrate for the next hydrothermal treatment, and dry the obtained solid product at 105° C. for 4 hours, and set aside;

[0068] 3) using a ball mill to perform ball milling on the dried solid product, and the ball milling time is 10 hours;

[0069] 4) Sieve the steel slag after ball milling, and separate four steel slags larger tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com