Preparation method of photoelectric component

A technology of optoelectronic components and light, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

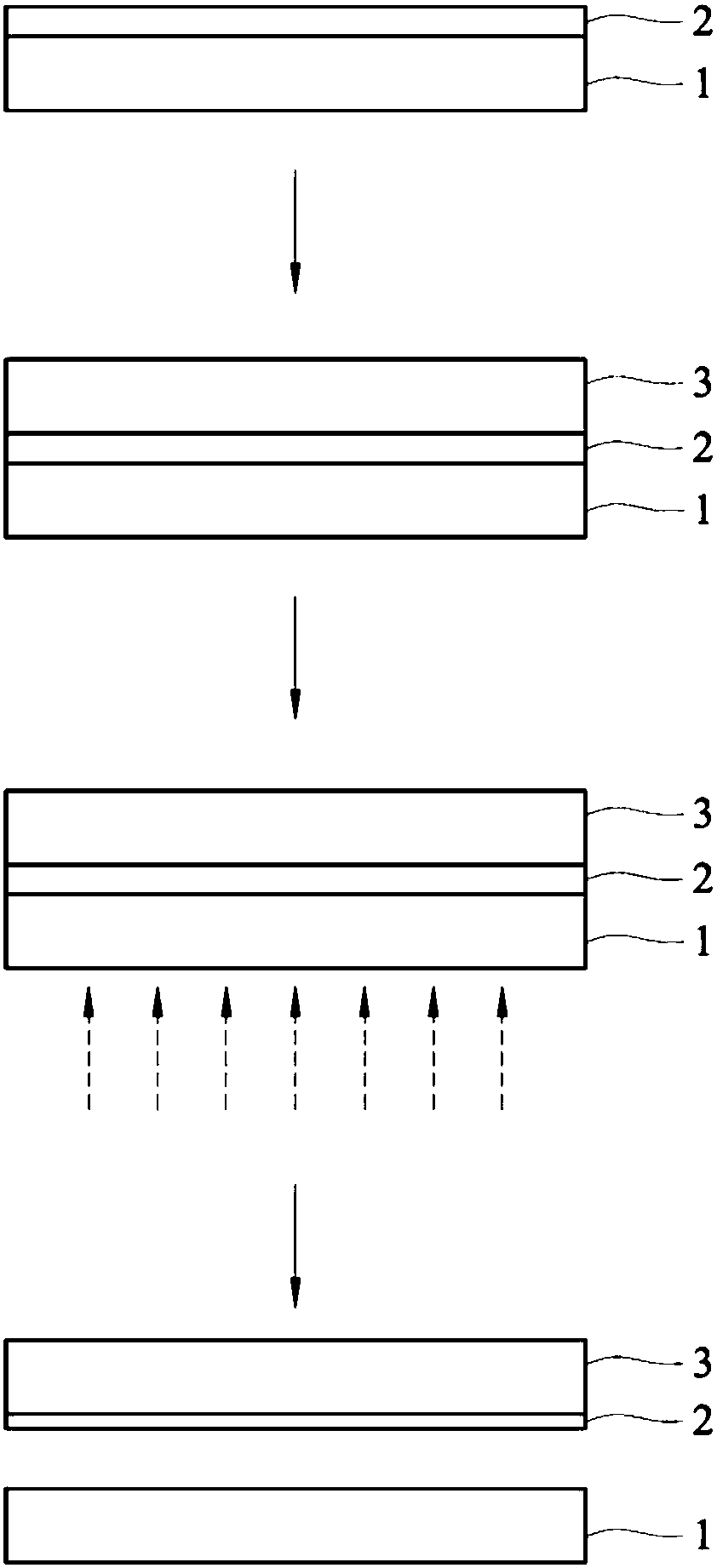

[0036] refer to figure 1 , the embodiment of the preparation method of the photoelectric element of the present invention comprises:

[0037] (a) Forming a polymer layer 2 on the carrier material 1, the polymer layer 2 is mainly a material that will degrade under light irradiation. In this embodiment, the polymer layer 2 is mainly made of polyimide material, and the polymer layer 2 is made by combining 2,2'-bis(trifluoromethyl)benzidine (TFMB) with 4, The polyimide formed by the reaction of 4'-oxydiphthalic anhydride (ODPA) and hexafluorodianhydride (6FDA) is coated on the glass carrier 1, and then heated at 300°C for dehydration and ring-closing reaction to form .

[0038] (b) forming a photoelectric element 3 on the polymer layer 2;

[0039] (c) irradiating the polymer layer 2 with light from the surface of the glass carrier, so that the polymer layer 2 is degraded, and the glass carrier 1 is separated from the photoelectric element 3; and

[0040] (d) Cleaning the optoele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com