Rapid preparation method of Ce:Cs2LiYCl6 crystal for gamma-ray and neutron dual detection

A technology of crystal and seed crystal, which is applied in the field of optoelectronic materials, can solve the problems of crystal security, wall adhesion, slow crystal growth speed, and difficult device processing, etc., and achieve the effects of avoiding thermal stress, saving time, and shortening the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) CsCl, LiCl and (YCl) with a purity of more than 99.9% 3+ CeCl 3 ) The raw materials are mixed evenly at a molar ratio of 2:1:1; put into a closed quartz crucible and heat up to 750°C, keep the temperature for 4 hours, the material is fully melted and the melt is mixed evenly; then it is cooled to room temperature at a rate of 50°C / hour, Ce:CLYC crystals are obtained by spontaneous nucleation, and the defect-free Ce:CLYC crystal parts are selected as seed crystals;

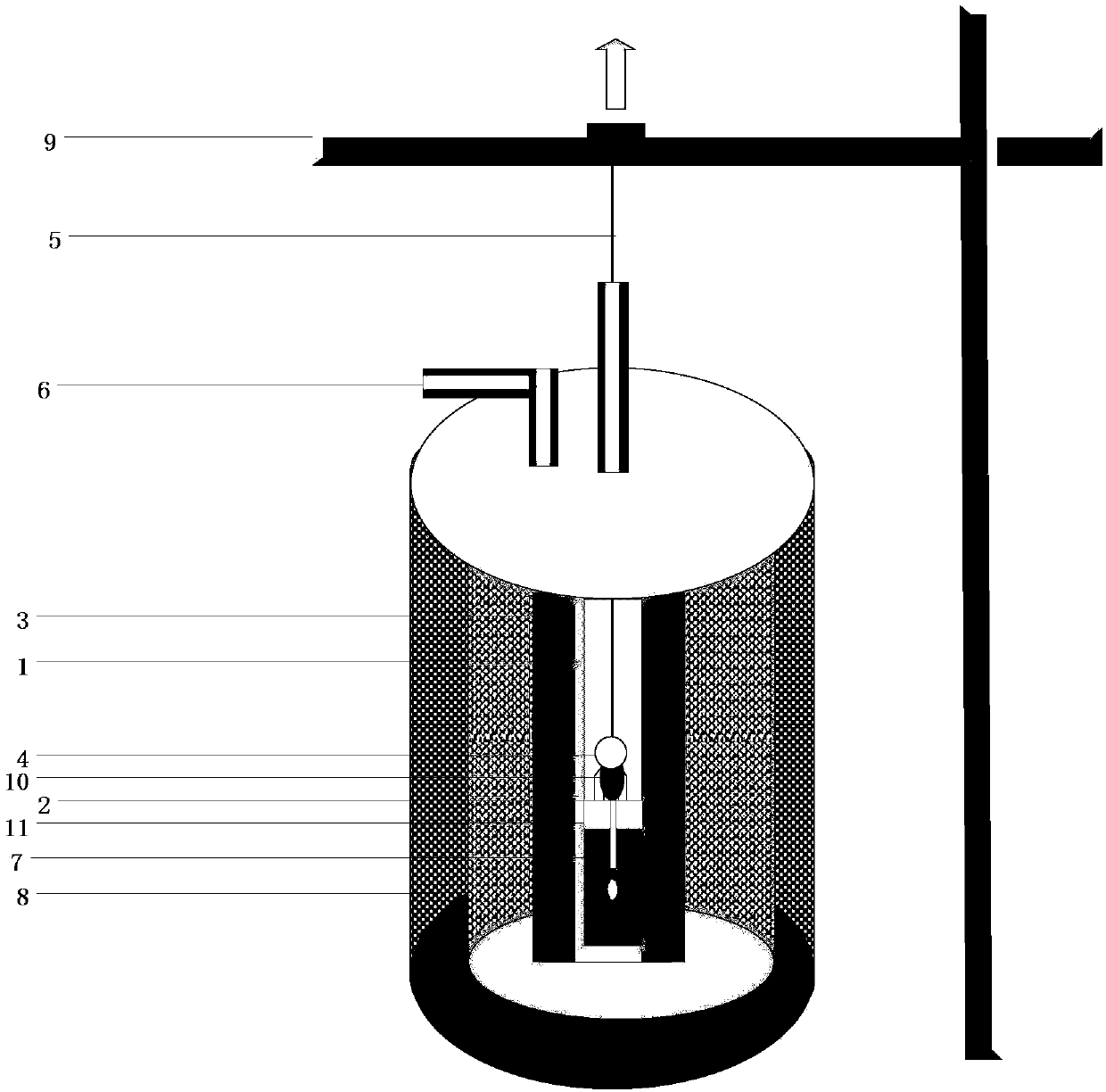

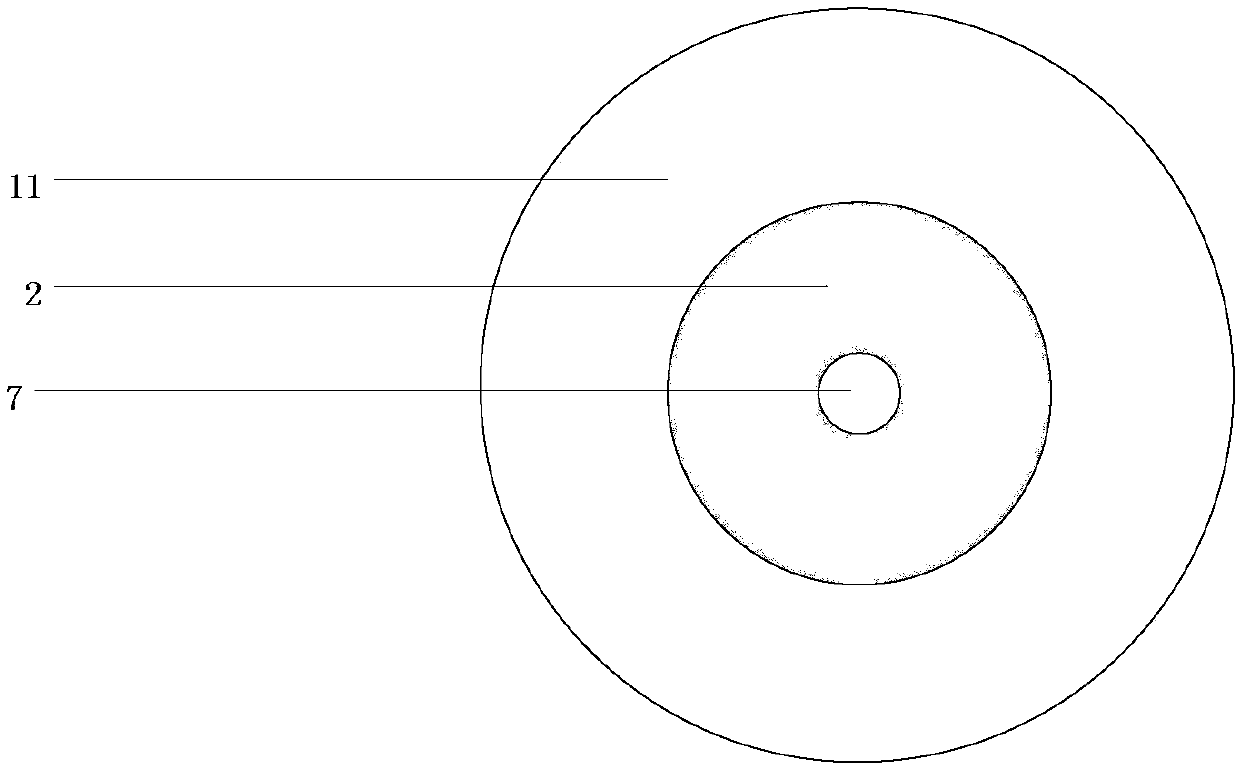

[0044] (2) Get raw materials CsCl, LiCl and (YCl) with a purity of more than 99.9% 3+ CeCl 3 ), mixed evenly at a molar ratio of 2:1:1 and put into a quartz crucible 1, placing a quartz mold 2 with a circular diameter of 12 mm on the edge and a meniscus-shaped longitudinal section on the raw material in the quartz crucible, and sealing them together in a In the quartz safety tube 3, the air is vacuumed out, and argon gas is filled from the air inlet 6, so that the air pressure in the safety tube is 0....

Embodiment 2

[0048] (1) The growth of seed crystal is as embodiment 1 step (1);

[0049] (2) As described in Example 1, the difference is that the mold used is a graphite mold with a square edge, and the edge size of the square mold is 4 millimeters.

[0050] Fill with argon to make the air pressure in the safety tube 0.01-0.02Pa; raise the temperature to 800°C to overheat the chemical material. Overheat at constant temperature for 3 hours to fully melt and mix the materials evenly. Connect the two capillary channels below in the center of the square graphite mold to transport the molten raw material liquid to the upper surface of the graphite mold and form a melt film on the upper surface; then fix the seed crystal in step (1) to the seed crystal rod Put it on the graphite mold and fully preheat it, then lower it to the melt film that touches the upper surface of the mold, then lower the temperature to 0.5°C above the melting point, with a pulling rate of 7mm / min, and a cooling rate of 2...

Embodiment 3

[0053] (1) The growth of seed crystal is as embodiment 1 step (1);

[0054] (2) Take the raw material CeCl with a purity of more than 99.9% 3 , LiCl and (CsCl+YCl 3 ), mixed evenly at a molar ratio of 2:1:1 and placed in a quartz crucible, and an aluminum nitride mold with a rectangular edge of 15 mm × 2 mm was placed in the quartz crucible. Raw material CeCl 3 , CsCl, LiCl and YCl 3 The above are hermetically sealed in a quartz safety tube, the air is evacuated, and the air is filled with argon so that the pressure in the safety tube is 0.03-0.04Pa; the temperature is raised to 800°C and the chemical material is overheated. Overheat at constant temperature for 3 hours to fully melt and mix the materials evenly. The aluminum nitride mold is evenly distributed with 3 through holes, and there are 3 capillary channels below to transport the molten raw material liquid to the upper surface of the mold and form a melt film on the upper surface; then the seed crystal of step (1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com