Method for surface coloration during chemical toughening of milky-white glass

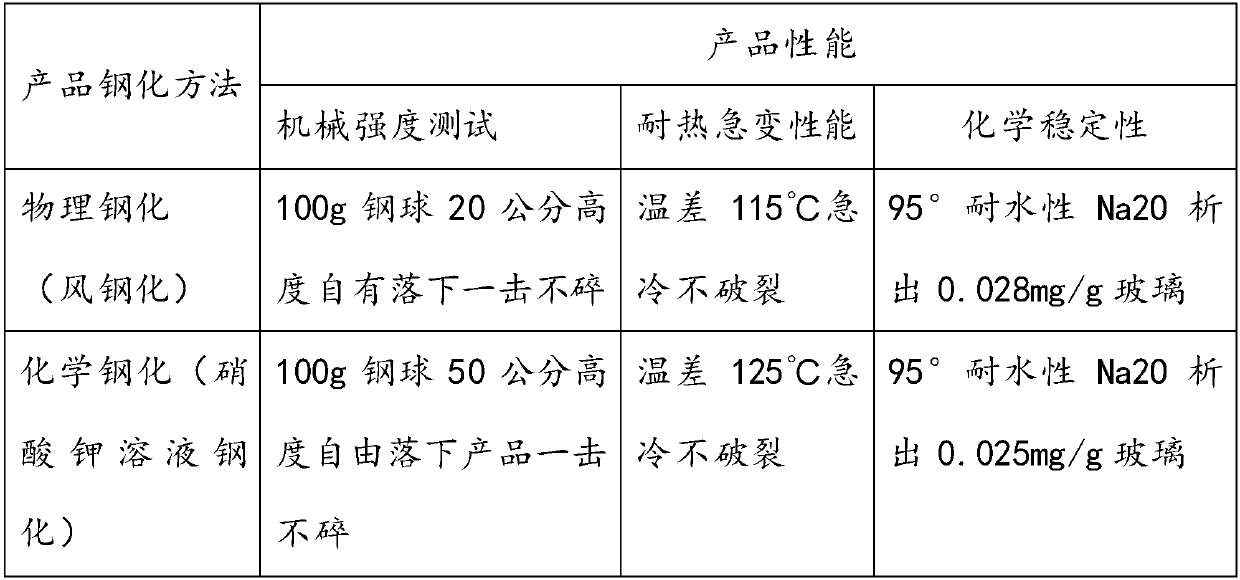

A milky white glass and chemical tempering technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complicated procedures, easy wear and tear, and large amount of colorant, so as to reduce the processing process, save energy and The effect of labor and appearance quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method of coloring the surface of milky white glass during chemical tempering. The production process of milky white glass products includes ingredients, mixing materials, stirring in the machine, spraying water, putting in the furnace, melting into glass liquid, feeding and forming, chemical tempering, and the uniformity of stirring in the machine It can reach more than 95%, spray water to make the moisture content about 19%, and the melting temperature is 1420-1450°C. When it is melted into glass liquid, it enters the ascending path of the flow hole, and the feeding path is cooled and homogenized. The temperature of the opal glass tableware when preparing for chemical tempering is 520°C, the temperature of the medium potassium nitrate liquid for chemical tempering is 400°C, 0.008% cobalt oxide (CoO) is added to the potassium nitrate liquid, and the opal glass is tempered while tempering. The tableware is colored, and the milky white glass tableware can be colored b...

Embodiment 2

[0038] The method of coloring the surface of milky white glass during chemical tempering. The production process of milky white glass products includes ingredients, mixing materials, stirring in the machine, spraying water, putting in the furnace, melting into glass liquid, feeding and forming, chemical tempering, and the uniformity of stirring in the machine It can reach more than 95%, spray water to make the moisture content about 19%, and the melting temperature is 1420-1450°C. When it is melted into glass liquid, it enters the ascending path of the flow hole, and the feeding path is cooled and homogenized. The temperature of the milk white glass tableware when preparing to carry out chemical toughening is 550°C, the temperature of the medium potassium nitrate liquid for chemical toughening is 450°C, and 0.012% cobalt oxide (CoO) is added to the potassium nitrate liquid to temper the milk white glass at the same time. The tableware is colored for 70 seconds, and the opal gla...

Embodiment 3

[0040] The method of coloring the surface of milky white glass during chemical tempering. The production process of milky white glass products includes ingredients, mixing materials, stirring in the machine, spraying water, putting in the furnace, melting into glass liquid, feeding and forming, chemical tempering, and the uniformity of stirring in the machine It can reach more than 95%, spray water to make the moisture content about 19%, and the melting temperature is 1420-1450°C. When it is melted into glass liquid, it enters the ascending path of the flow hole, and the feeding path is cooled and homogenized. The temperature of the opal glass tableware when preparing for chemical tempering is 535°C, the temperature of the medium potassium nitrate liquid for chemical tempering is 350°C, and 0.010% cobalt oxide (CoO) is added to the potassium nitrate liquid to temper the opal glass while tempering. The tableware is colored for 80 seconds, and the opal glass tableware can be colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com