Upper moulding bed and chord cold pressing forming device

A tire mold, strip technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the manufacturing cost of chords, and achieve the effects of improving molding quality, ensuring stability, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

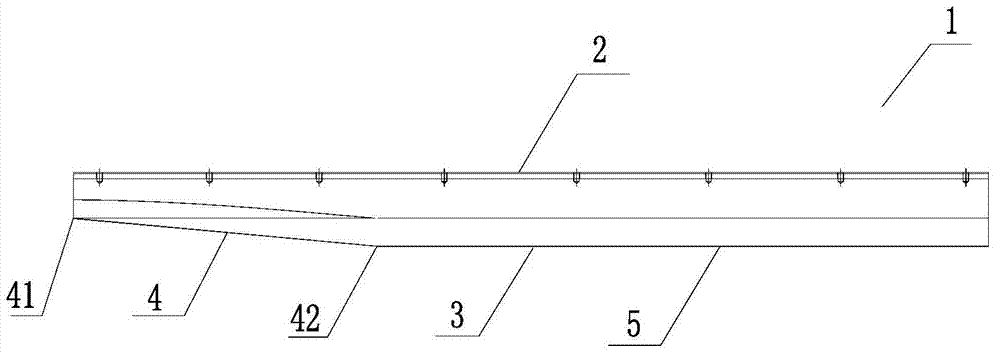

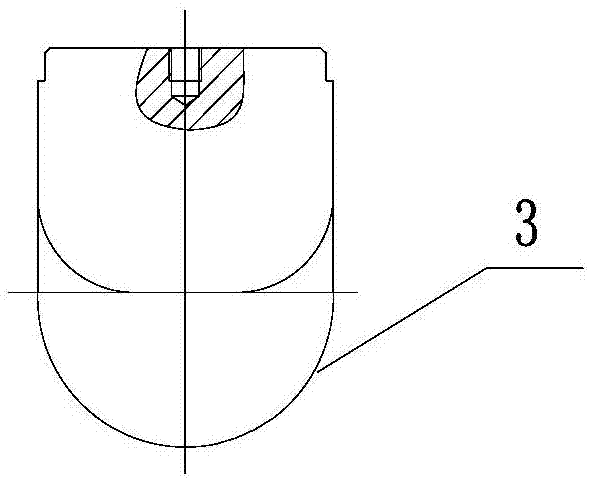

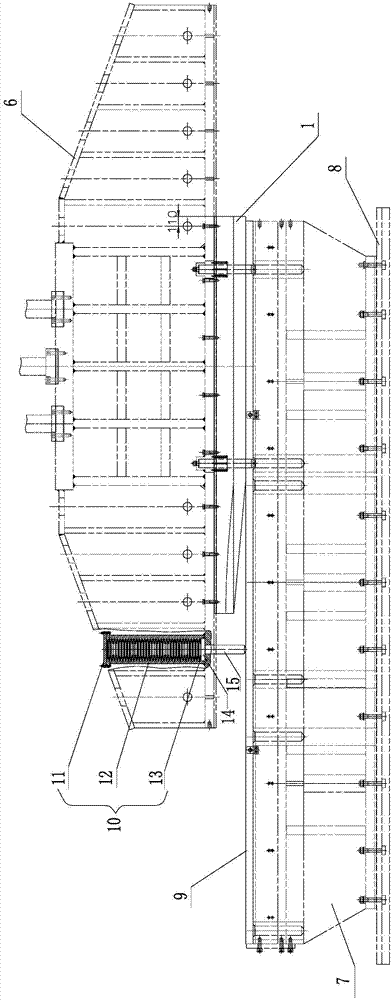

[0025] Please refer to Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the front view structure of the upper tire mold of the present invention; figure 2 It is a side view structural schematic diagram of the upper tire mold of the present invention; image 3 It is a structural schematic diagram of the chord cold forming device of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com