A freely adjustable micro-nano machining platform

A processing platform and nanomachine technology, applied in the direction of workbench, nanotechnology, manufacturing tools, etc., can solve the problems of damage to processing objects, unguaranteed processing quality, and difficulty in ensuring processing quality, and achieve a high degree of automation and adjustment process. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

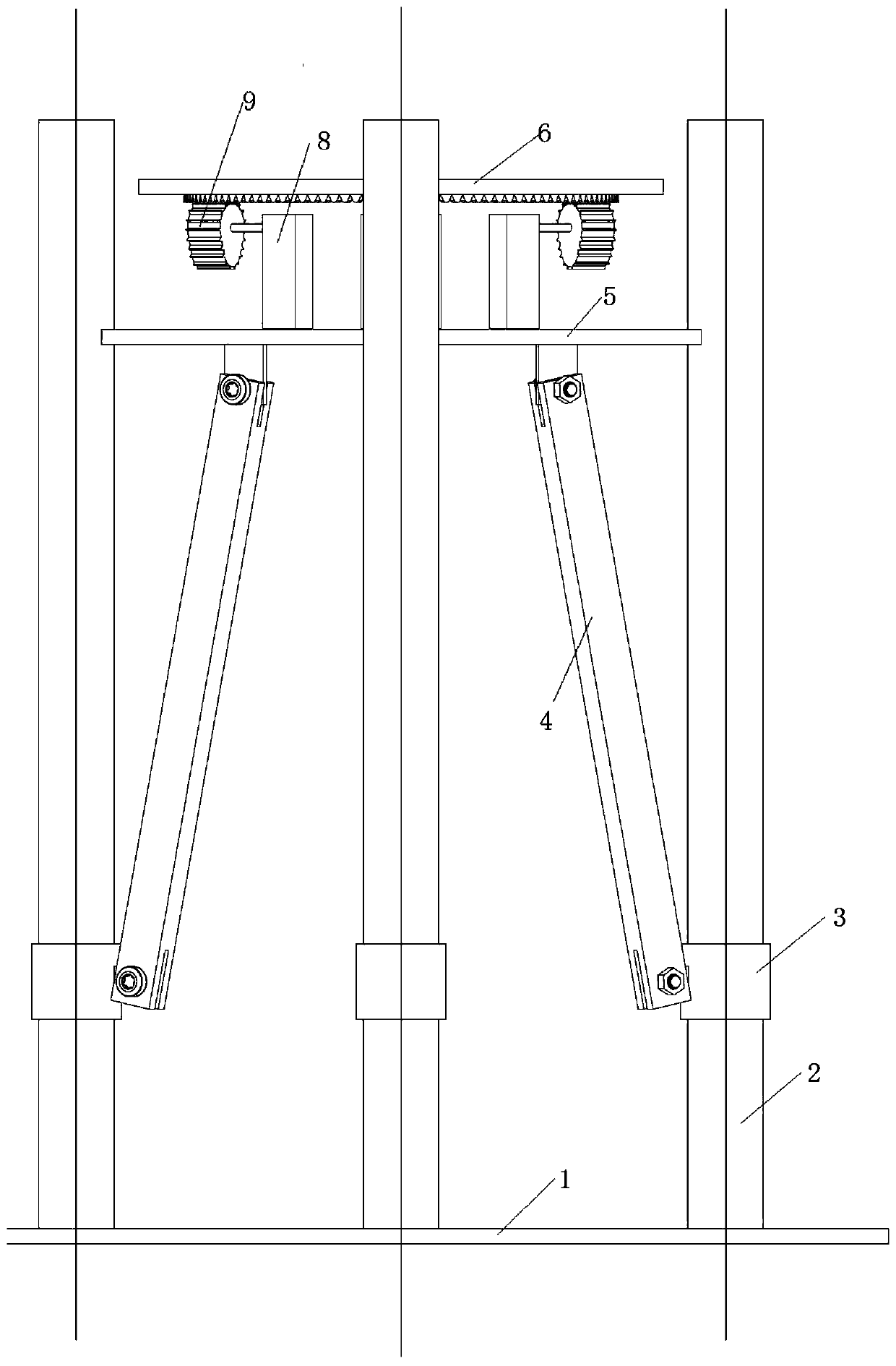

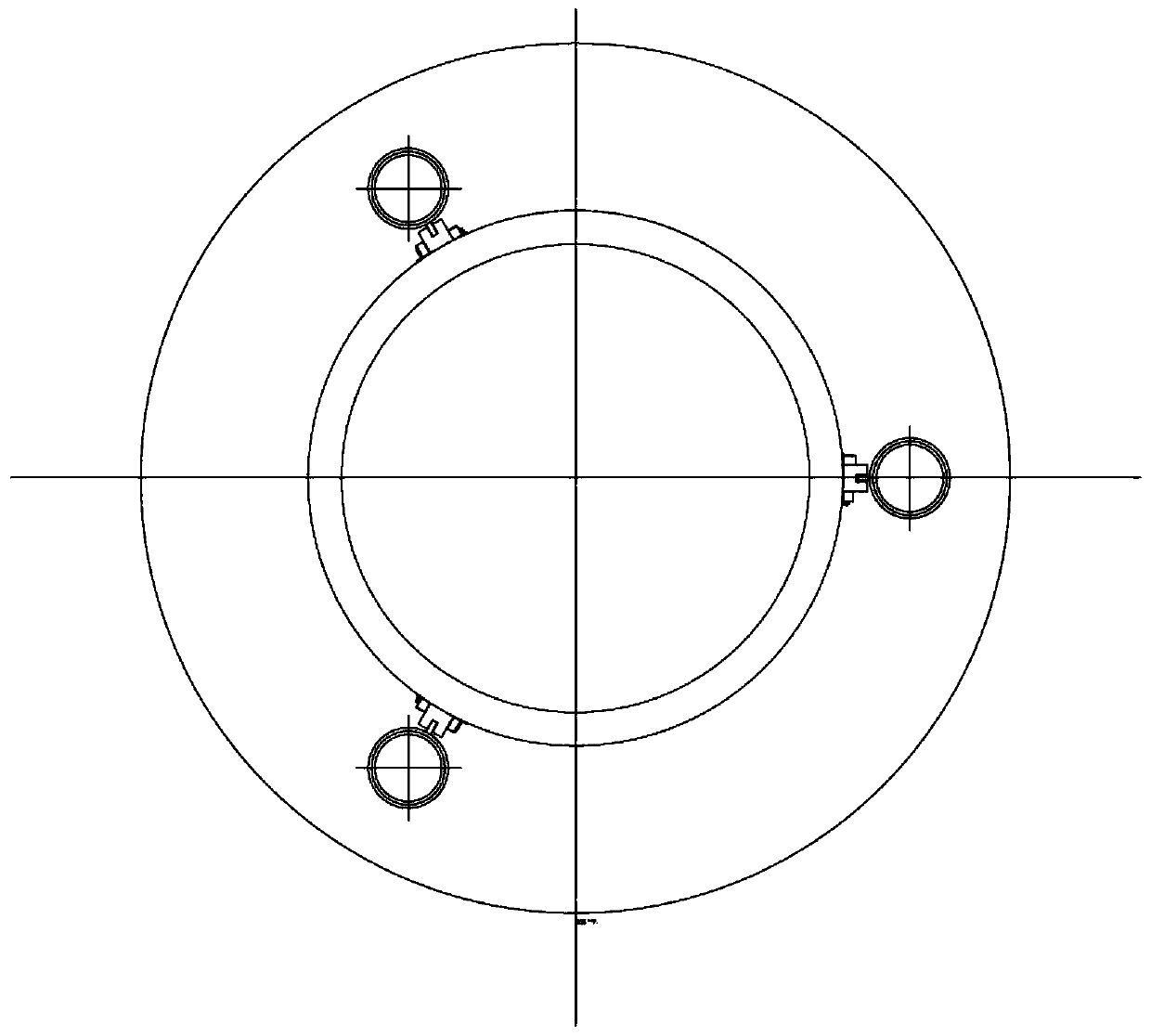

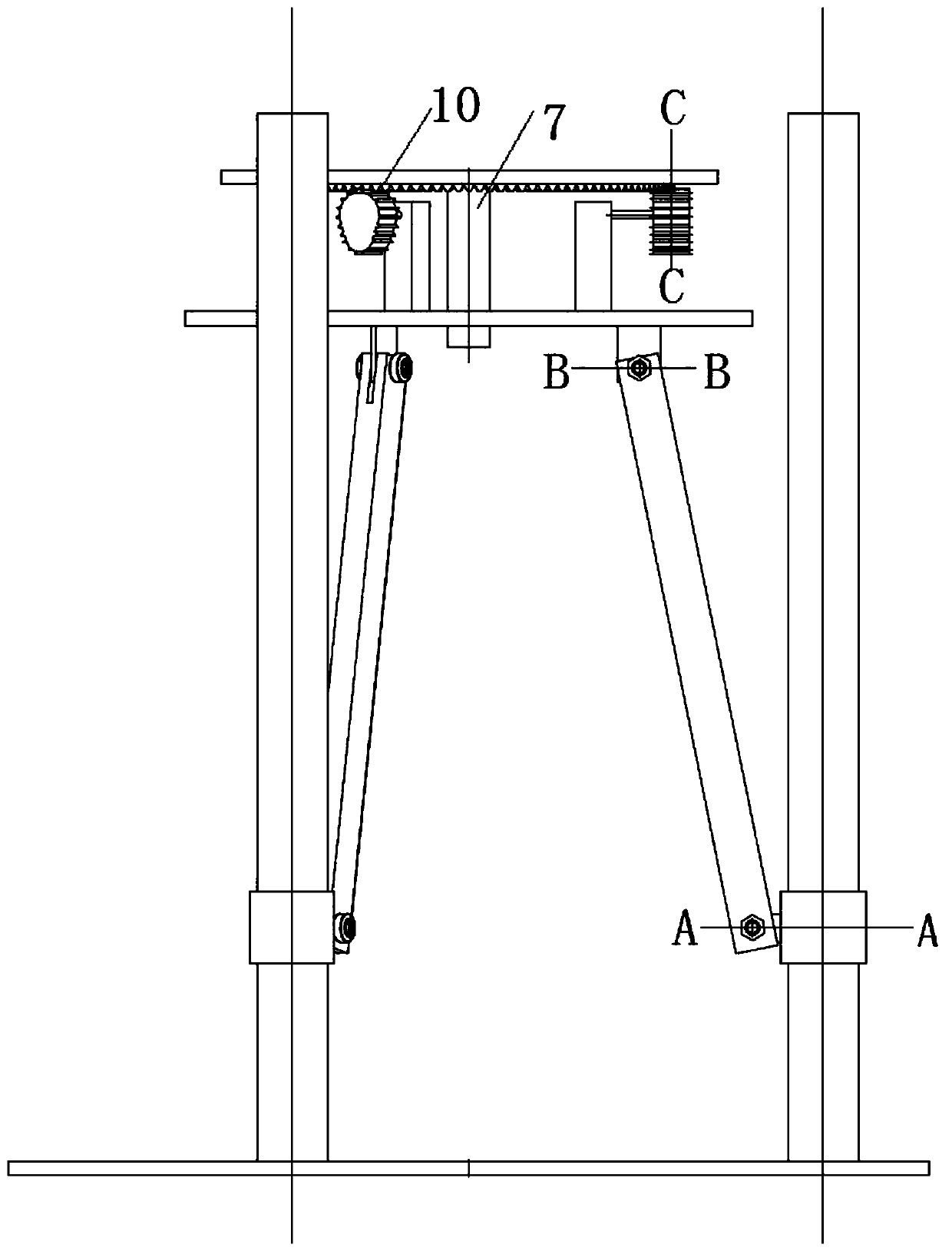

[0026] like Figure 1-7 As shown, a freely adjustable micro-nano machining platform, the micro-nano machining platform includes a base 1, a column 2, a slider seat 3, a support link 4, a bottom platform 5, a top platform 6, and a central connection support column 7 , drive motor 8, wedge gear 9 and ring rack 10.

[0027] Three columns 2 are vertically and evenly arranged on the base 1 along the circumferential direction, and each column 2 is provided with a slider seat 3; the slider seat 3 can move vertically and rotate in the circumferential direction along the column 2, and the bottom platform 5 It is connected with the slider seat 3 through the supporting connecting rod 4; the three supporting connecting rods 4 support the bottom platform 5 along the circumferential direction, and the three driving motors 8 are evenly distributed on the bottom platform 5, and the output shaft of the driving motor 8 is connected with the wedge gear 9 Connection; the top platform 6 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com