Pulsating negative pressure laser enhanced ktig and mig composite welding device and method

A composite welding and negative pressure device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex welding equipment, shallow welding penetration, slow TIG welding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

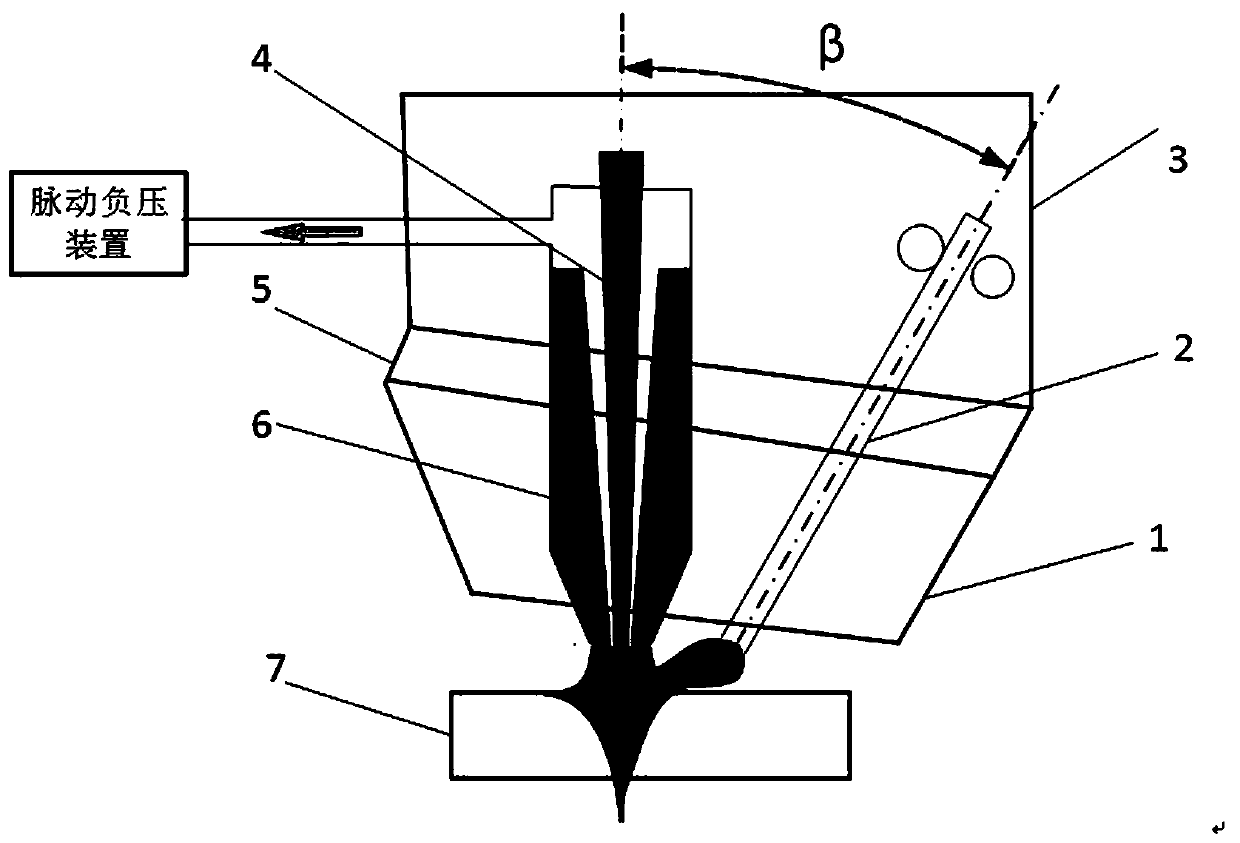

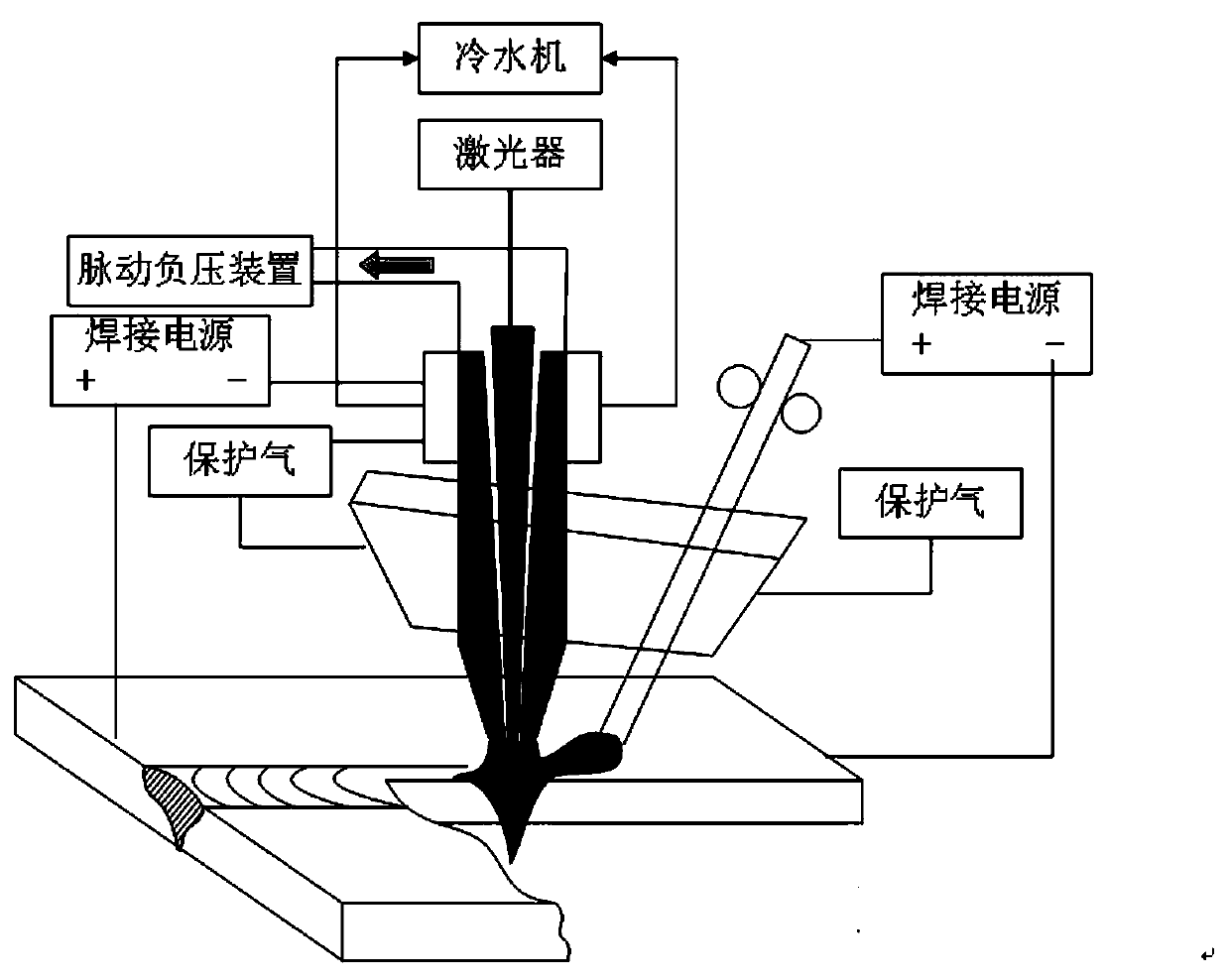

[0023] like Figure 1-2 As shown, the pulsating negative pressure laser-enhanced KTIG and MIG composite welding device includes a hollow tungsten electrode 6 , a laser beam 4 , a MIG welding torch 2 , a welding torch bracket 3 , a shielding gas cover 1 , and a welding base 5 . The pulsating negative pressure device makes the inside of the hollow tungsten electrode 6 reach a state of pulsating negative pressure. The laser beam 4 is generated by the laser and passes through the hollow tungsten electrode 6 to achieve coaxial recombination of the laser beam and the KTIG arc. The hollow tungsten electrode 6 and the MIG welding torch 2 form a KTIG - MIG composite welding torch, the composite welding torch is fixed on the welding base 5 through screw connection, the welding base 5 is fixed on the welding support 3 through bolt connection; the shielding gas cover 1 is fixed on the welding base 5 through screw connection.

[0024] The welding power supply includes KTIG welding power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com