Activation method for adsorbent for removing oxygenates in light olefins

A low-carbon olefin and activation method technology, which is applied in chemical instruments and methods, adsorption purification/separation, separation methods, etc., can solve the problems of adsorbent adsorption performance attenuation, adsorbent easy to coke and carbon deposition, low regeneration efficiency, etc., to achieve Slow aggregation, good activation effect, avoid coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

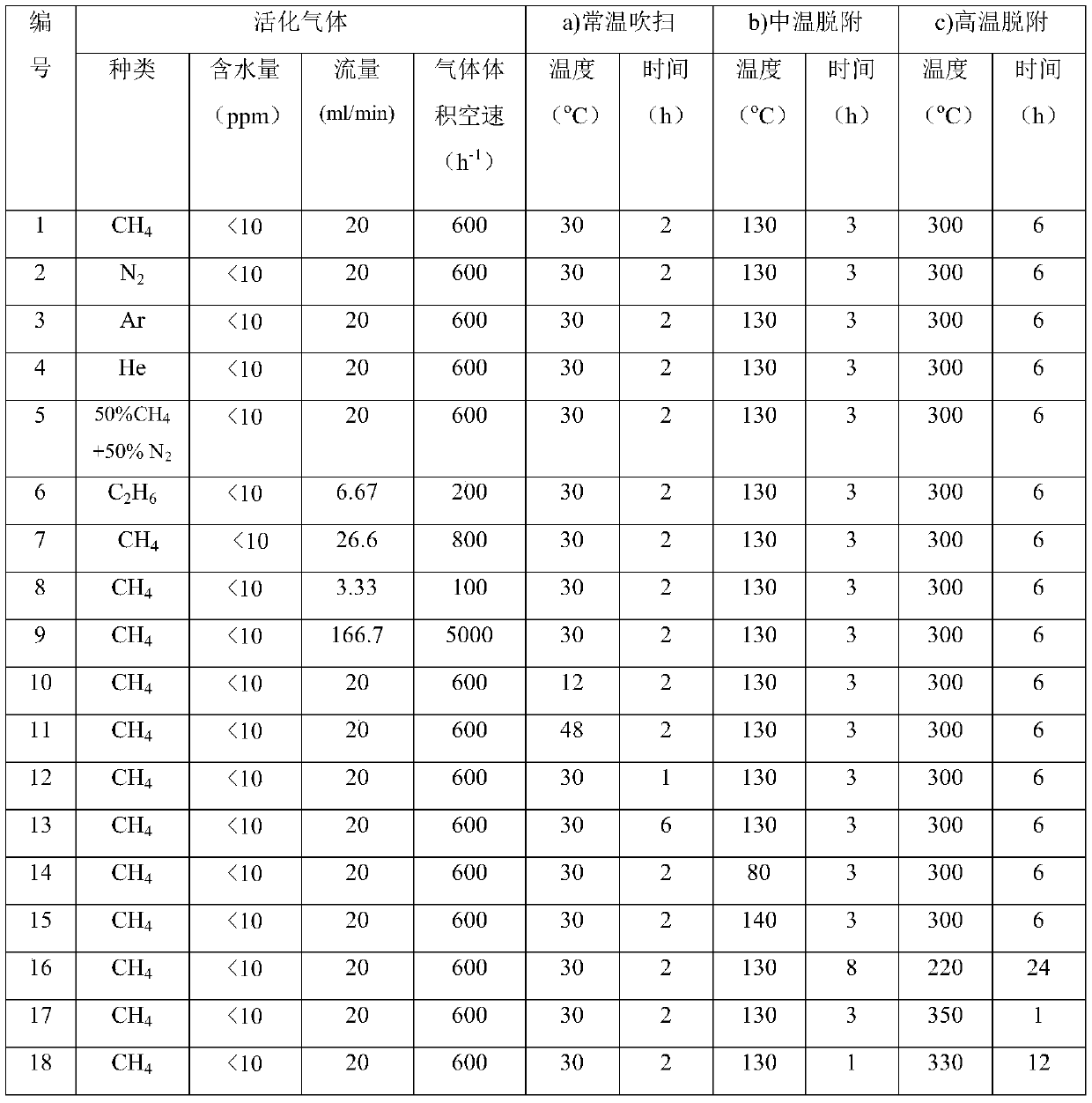

Examples

Embodiment 1

[0018] The solid adsorbent used in the present invention is to adopt Zn 2+ Ion-exchange modified Y-type molecular sieves for the adsorption and removal of oxygenates from mixed C4 hydrocarbons. In the experiment, dimethyl ether in a C4 hydrocarbon stream is used as a probe molecule to remove oxygen-containing impurities. The content of dimethyl ether was 150 ppmw based on the total weight of the supplied C4 hydrocarbon stream. The adsorption evaluation conditions are: at 2.0MPa, 35°C, 2h -1 The volumetric space velocity of the liquid is 2ml, and the loading capacity of the adsorbent is 2ml. The appearance of the adsorbent is a cylindrical particle with a particle diameter of 10-20 mesh.

[0019] Before the adsorbent is in contact with the C4 hydrocarbon material to be purified, it needs to be activated. The activation process and specific conditions are: the gas used for activation is CH with a water content lower than 10ppm 4 gas, first at room temperature 30°C under cons...

Embodiment 2

[0022] The solid adsorbent used in the present invention is to adopt Zn 2+ Ion-exchange modified Y-type molecular sieves for the adsorption and removal of oxygenates from mixed C4 hydrocarbons. In the experiment, dimethyl ether in a C4 hydrocarbon stream is used as a probe molecule to remove oxygen-containing impurities. The content of dimethyl ether was 150 ppmw based on the total weight of the supplied C4 hydrocarbon stream. The adsorption evaluation conditions are: at 2.0MPa, 35°C, 2h -1 The volumetric space velocity of the liquid is 2ml, and the loading capacity of the adsorbent is 2ml. The appearance of the adsorbent is a cylindrical particle with a particle diameter of 10-20 mesh.

[0023] Before the adsorbent is in contact with the C4 hydrocarbon material to be purified, it needs to be activated. The activation process and specific conditions are: the gas used for activation is N with a water content below 10ppm 2 Gas, first at room temperature 30°C, the gas volume ...

Embodiment 3

[0026] The solid adsorbent used in the present invention is to adopt Zn 2+Ion-exchange modified Y-type molecular sieves for the adsorption and removal of oxygenates from mixed C4 hydrocarbons. In the experiment, dimethyl ether in a C4 hydrocarbon stream is used as a probe molecule to remove oxygen-containing impurities. The content of dimethyl ether was 150 ppmw based on the total weight of the supplied C4 hydrocarbon stream. The adsorption evaluation conditions are: at 2.0MPa, 35°C, 2h -1 The volumetric space velocity of the liquid is 2ml, and the loading capacity of the adsorbent is 2ml. The appearance of the adsorbent is a cylindrical particle with a particle diameter of 10-20 mesh.

[0027] Before the adsorbent is in contact with the C4 hydrocarbon material to be purified, it needs to be activated. The activation process and specific conditions are: the gas used for activation is Ar gas with a water content of less than 10ppm. First, at room temperature 30°C, the gas vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com