Processing method of fruit and vegetable chips through pulsating vacuum in-situ steam explosion

A technology of pulsating vacuum and fruit and vegetable crisps, which is applied in the field of food processing, can solve the problems of long processing time of food materials, no processing of fruit and vegetable crisps, and damage to products, so as to reduce quality loss, increase thermal conductivity, and improve heating speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Wash, peel, and slice fresh potatoes. The thickness of the potato slices is 2mm. Blanch the potato slices with hot water at a temperature of 60°C for 5 minutes. After dissolving in hot water at 50°C, the soaking liquid is obtained, soaking for 30 minutes;

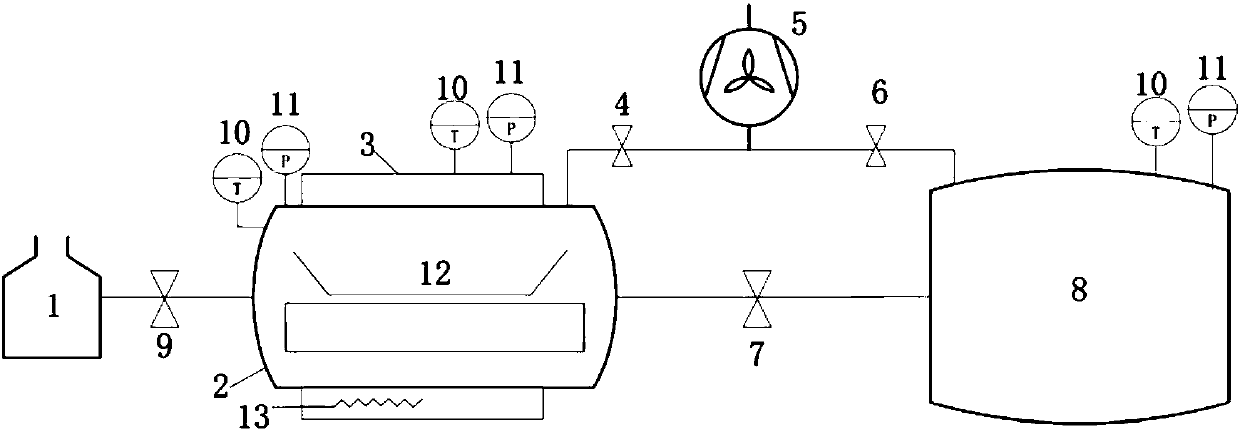

[0031] Remove the soaked potato slices and dry them until there is no water dripping on the surface, put them into the pulsating vacuum in-situ steam explosion tank, turn on the jacket heating system, open the valve of the steam explosion tank connected to the vacuum pump, and control the vacuum degree in the steam explosion tank to -0.08MPa, close the vacuum valve, open the steam valve, feed 160°C saturated steam, maintain the temperature in the tank for 1min, close the steam valve, open the valve connecting the steam explosion tank and buffer tank for the first expansion, close the steam explosion tank and buffer tank Tank connection valves;

[0032] Open the valve connecting the steam explosion tank to the vacuum...

Embodiment 2

[0035] Wash, peel, and slice the apples. The thickness of the fruit and vegetable slices is 2mm. Blanch the apple slices with hot water at a temperature of 40°C for 4 minutes. After dissolving in hot water at ℃, the soaking solution is obtained, soaking for 30 minutes;

[0036] Take out the apple slices soaked above, filter and dry until there is no water dripping on the surface, put them into the pulsating vacuum in-situ steam explosion tank, turn on the jacket heating system, open the valve of the steam explosion tank connected to the vacuum pump, and control the vacuum degree in the steam explosion tank to -0.08MPa, close the vacuum valve, open the steam valve, feed 130°C saturated steam, maintain the temperature in the tank for 1min, close the steam valve, open the valve connecting the steam explosion tank and buffer tank for the first expansion, close the steam explosion tank and buffer tank Tank connection valves;

[0037] Open the valve connecting the steam explosion t...

Embodiment 3

[0040] Peel and slice bananas with a thickness of 3mm. Dissolve food-grade pullulan, trehalose, fructose, edible salt, and citric acid in hot water at a temperature of 50°C to obtain a soaking solution, and soak for 30 minutes;

[0041] Put the above-mentioned banana slices into the pulsating vacuum in-situ steam explosion tank, open the jacket heating system, open the valve of the steam explosion tank connected to the vacuum pump, control the vacuum degree in the steam explosion tank to be -0.06MPa, close the vacuum valve, open the steam valve, Inject saturated steam at 120°C, maintain the temperature in the tank for 0.5 minutes, close the steam valve, open the valve connecting the steam explosion tank and the buffer tank for the first expansion, and close the connection valve between the steam explosion tank and the buffer tank;

[0042] Open the valve connecting the steam explosion tank to the vacuum pump, control the vacuum degree in the steam explosion tank at -0.05MPa, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com