A UWB Microstrip Vertical Transition Based on Single-Layer Microwave Dielectric

A microwave medium and vertical transition technology, applied in the electronic field, can solve the problems of inaccuracy and inapplicability, and achieve the effect of simplifying the process of process realization, high processing precision and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

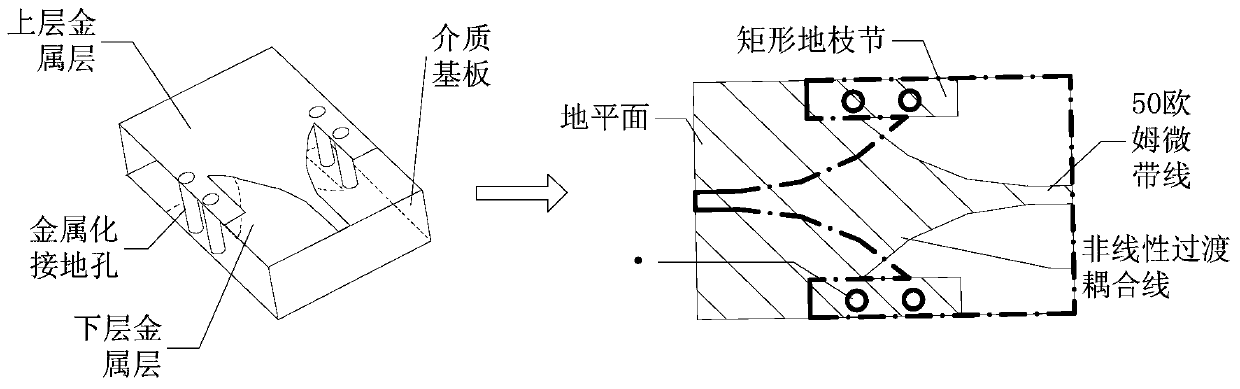

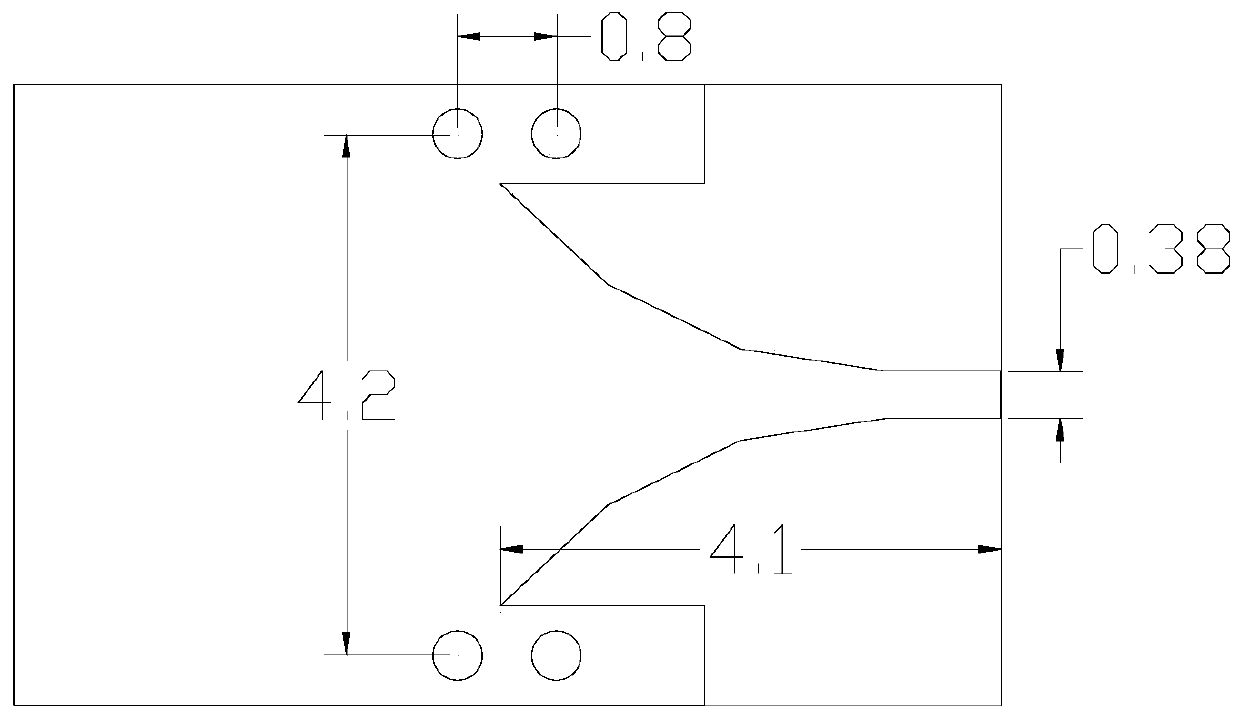

[0030] The present invention takes a microstrip vertical transition from X to Ka frequency band based on a single-layer ceramic medium as an example. Such as figure 2 As shown, the dielectric substrate material uses the ceramic substrate material A493, the relative dielectric constant is 9.9, and the dielectric thickness is 0.38mm.

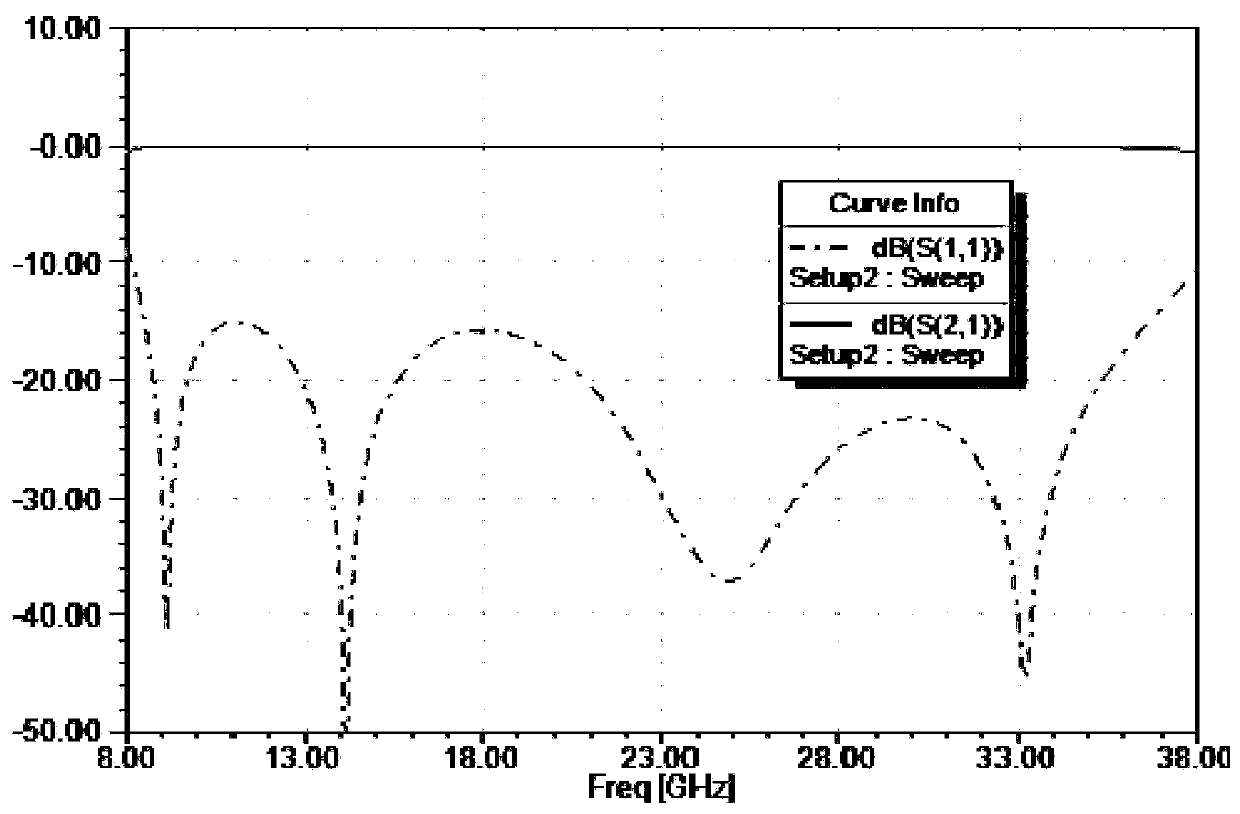

[0031] Its topology has been described in detail above, and its specific dimensions are as follows figure 2 shown. The simulation results of the new ultra-wideband high-frequency microstrip vertical transition in this example are as follows: image 3 As shown, dB(S(1,1)) is its reflection loss, and dB(S(2,1)) is its insertion loss. Its frequency band can cover 8GHz to 38GHz, and the bandwidth can reach 30GHz, and it can be easily improved by reducing the corresponding size. Use frequencies up to the mmWave band.

Embodiment 2

[0033] Such as Figure 4 As shown, the A493 ceramic medium is also used, and the thickness of the medium is 0.254mm. The simulation results are as follows Figure 5 As shown, dB(S(1,1)) is its reflection loss, and dB(S(2,1)) is its insertion loss, and its transmission performance can cover the entire frequency band from 18GHz to 50GHz.

[0034] In summary, the ultra-broadband high-frequency microstrip vertical transition method proposed by the present invention has simple implementation form, flexible design, high applicable frequency, wide applicable bandwidth, excellent standing wave in the band, and can be applied to various required radio frequency microwave system or circuit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com