Device used for edge folding of lithium battery and application method thereof

A lithium battery and bending technology, which is applied in the direction of secondary batteries, battery pack parts, battery boxes/coats, etc., can solve the problems of low safety of folding, poor quality of folding, and easy burns of workers, etc., and achieves improvement. The effect of improving the quality of hemming and improving the safety of hemming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

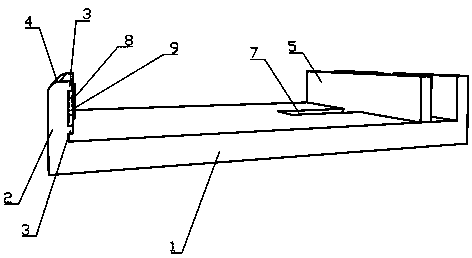

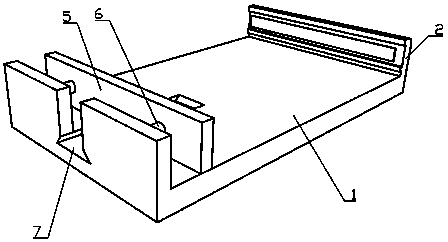

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0023] See attached figure 1 and 2 , the device for lithium battery folding in the figure includes an integrally formed horizontal base 1 and a vertical base 2, characterized in that: the vertical base 2 is located above the horizontal base 1 and is located on the horizontal base The left side of platform 1, the right side of described vertical abutment 2 are provided with two positioning bosses 3, and two described positioning bosses 3 are distributed up and down on the right side panel of vertical abutment 2, two The rightmost end of the positioning boss 3 is located on the same vertical surface, the positioning boss 3 is strip-shaped and two positioning bosses 3 are arranged in parallel;

[0024] The upper right side of the horizontal base 1 is provided with a limited base.

[0025] In the above embodiment, preferably: the left side of the upper end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com