A kind of preparation method of high-capacity high-density high-nickel positive electrode material

A high-density, high-density technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems such as insufficient precursor compaction, avoid material capacity loss, and avoid cycle performance. The effect of deteriorating and increasing the unit cell volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

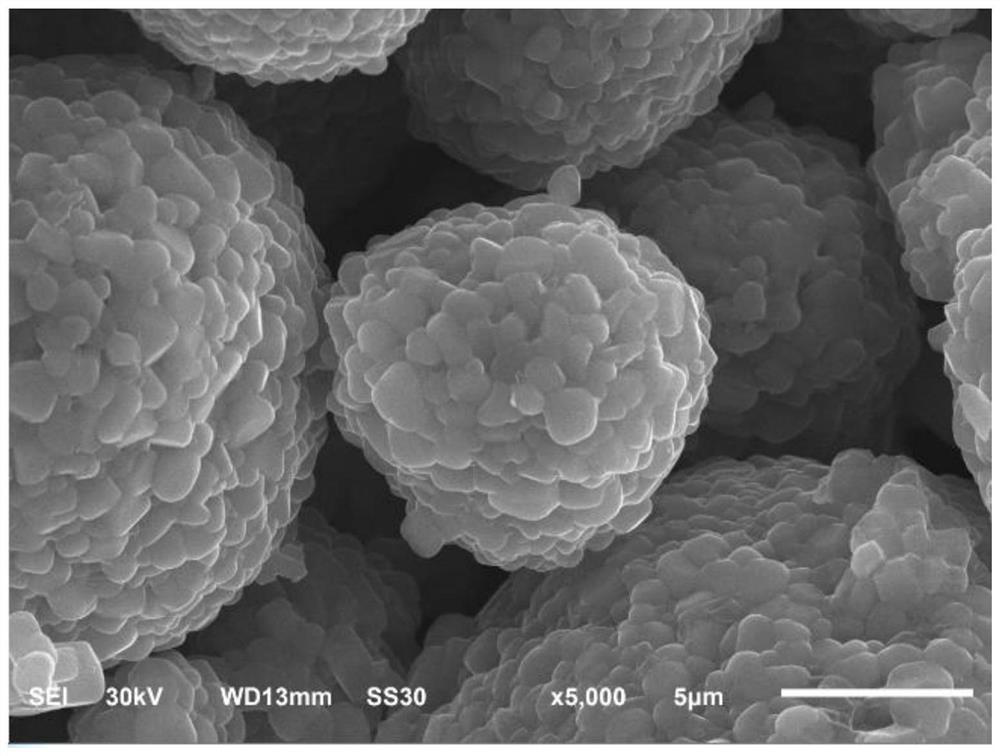

[0029] First weigh the large particle precursor Ni according to the mass ratio of 7:3 0.92 co 0.06 al 0.02 (OH) 2 (D50: 11.75um) 1400g and small particle precursor Ni 0.92 co 0.06 al 0.02 (OH) 2 600g (D50: 3.69um) and 4.462g Y 2 o 3 , the above three were mixed in a high mixer at 500r / min for 20min, and then sintered at 500°C with an oxygen flow rate of 15L / min for 6h to cool down naturally, and passed through a 300-mesh sieve to obtain the pretreated intermediate; the above intermediate solid and 25.191g MgO, 950.4g battery grade lithium hydroxide (Li / Me=1.05, purity 99.1%, particle size D50 is 5.17um) mixed in a high mixer at 500r / min for 30min, and then the mixed powder was placed In the sintering furnace, the oxygen flow rate is 16L / min, and the temperature is raised to 500°C at 1°C / min and kept for 4 hours, and then the temperature is raised to 700°C at 0.6°C / min and held for 16 hours, and then it is naturally lowered to room temperature and crushed through a 300...

Embodiment 2

[0032] First weigh the large particle precursor Ni according to the mass ratio of 8:2 0.90 co 0.04 al 0.06 (OH) 2 (D50: 13.0um) 1600g and small particle precursor Ni 0.90 co 0.04 al 0.06 (OH) 2 400g (D50: 4.52um) and 6.682g SnO 2, the above three were mixed in a high mixer at 400r / min for 30min, and then sintered at 600°C with an oxygen flow rate of 10L / min for 6h to cool down naturally, and passed through a 300-mesh sieve to obtain the pretreated intermediate; the above intermediate body with 30.25g ZrO 2 , 934.89g of battery-grade lithium hydroxide (Li / Me=1.03, purity 99.1%, particle size D50 is 5.17um) was mixed in a high mixer at 600r / min for 20min, and then the mixed powder was placed in a sintering furnace With an oxygen flow rate of 15L / min, heat at 1°C / min to 550°C for 4 hours, then raise the temperature at 0.8°C / min to 730°C and hold for 15 hours, then cool down to room temperature naturally, then crush and pass through a 300-mesh sieve to obtain a high compa...

Embodiment 3

[0035] First weigh the large particle precursor Ni according to the mass ratio of 7:3 0.8 co 0.1 mn 0.1 (OH) 2 (D50: 13.8um) 1400g and small particle precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 600g (D50: 4.07um) and 3.346g Y 2 o 3 , the above three were mixed in a high mixer at 500r / min for 20min, and then sintered at 600°C with an oxygen flow rate of 10L / min for 4h to cool down naturally, and passed through a 300-mesh sieve to obtain the pretreated intermediate; the above intermediate body with 28.23g Al 2 o 3 , 923.28g of battery-grade lithium hydroxide ((Li / Me=1.02, purity 99.1%, particle diameter D50 is 5.17um) was mixed with 500r / min for 40min in the high mixer, and then the mixed powder was placed in the sintering furnace With an oxygen flow rate of 15L / min, heat at 1°C / min to 600°C for 6 hours, then raise the temperature at 1°C / min to 770°C and hold for 16 hours, then naturally cool down to room temperature and then crush through a 300-mesh sieve to obtain a high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com