A flame heating method for rail cladding alloy strip

A technology of cladding alloy and flame heating, which is applied to metal material coating process, coating and other directions, can solve the problems of slow cladding movement, heavy equipment, slow construction speed, etc., and achieve the effect of good comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method of flame heating a rail cladding alloy strip, comprising the following steps:

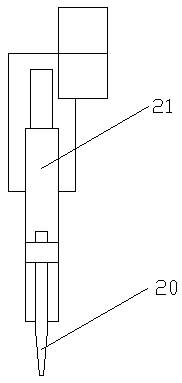

[0056] a. First place the rail cladding machine on the rail, and then arrange the flame head 20 on the rail cladding machine above the alloy strip after cladding;

[0057] b. Using the mixed gas formed by liquefied gas and oxygen as the heating gas source, the pressure ratio of liquefied gas and oxygen is 1:2.5, and mixing the liquefied gas and oxygen directly on the flame head 20;

[0058] c. After cladding the alloy strip to stand still for 2 seconds, start to move the flame head 20 at a constant speed along the X-axis to heat the alloy strip, so that the structure of the heat-affected zone of the rail after heating is tempered sorbite or tempered cord Troostite + tempered troostite or tempered troostite shall prevail.

[0059] The structure of the heat-affected zone of the rail after heating is tempered sorbite or tempered sorbite + tempered troostite or tempered troostite refer...

Embodiment 2

[0062] A method of flame heating a rail cladding alloy strip, comprising the following steps:

[0063] a. First place the rail cladding machine on the rail, and then arrange the flame head 20 on the rail cladding machine above the alloy strip after cladding;

[0064] b. Using the mixed gas formed by liquefied gas and oxygen as the heating gas source, the pressure ratio of liquefied gas and oxygen is 1:2.5, and mixing the liquefied gas and oxygen directly on the flame head 20;

[0065] c. After cladding the alloy strip to stand still for 20 seconds, start to move the flame head 20 at a constant speed along the X-axis direction to heat the alloy strip, so that the structure of the heat-affected zone of the rail after heating is tempered sorbite or tempered cord Troostite + tempered troostite or tempered troostite shall prevail.

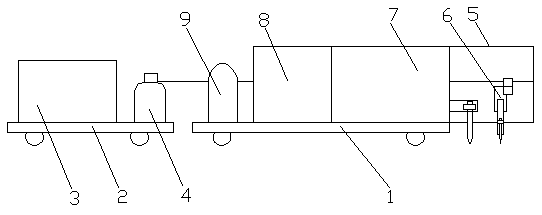

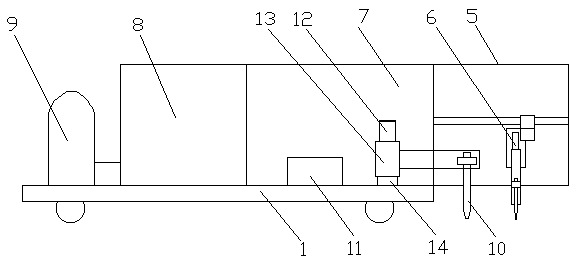

[0066] The rail cladding machine includes a first mobile trolley 1, a second mobile trolley 2, a cladding heating device, a power supply device 3 and ...

Embodiment 3

[0069] A method of flame heating a rail cladding alloy strip, comprising the following steps:

[0070] a. First place the rail cladding machine on the rail, and then arrange the flame head 20 on the rail cladding machine above the alloy strip after cladding;

[0071] b. Using the mixed gas formed by liquefied gas and oxygen as the heating gas source, the pressure ratio of liquefied gas and oxygen is 1:2.5, and mixing the liquefied gas and oxygen directly on the flame head 20;

[0072] c. After cladding the alloy strip to stand still for 60 seconds, start to move the flame head 20 at a constant speed along the X-axis to heat the alloy strip, so that the structure of the heat-affected zone of the rail after heating is tempered sorbite or tempered cord Troostite + tempered troostite or tempered troostite shall prevail.

[0073] The rail cladding machine includes a first mobile trolley 1, a second mobile trolley 2, a cladding heating device, a power supply device 3 and an air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com