Method for refining sugammadex sodium

A technology of sugammadex sodium and a purification method, applied in the field of pharmaceutical production, can solve the problems of not considering the protection of inert gas atmosphere, increasing the difficulty of purifying products, destroying impurities, etc., and achieving good economy, low cost and less impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Purification of sugammadex sodium

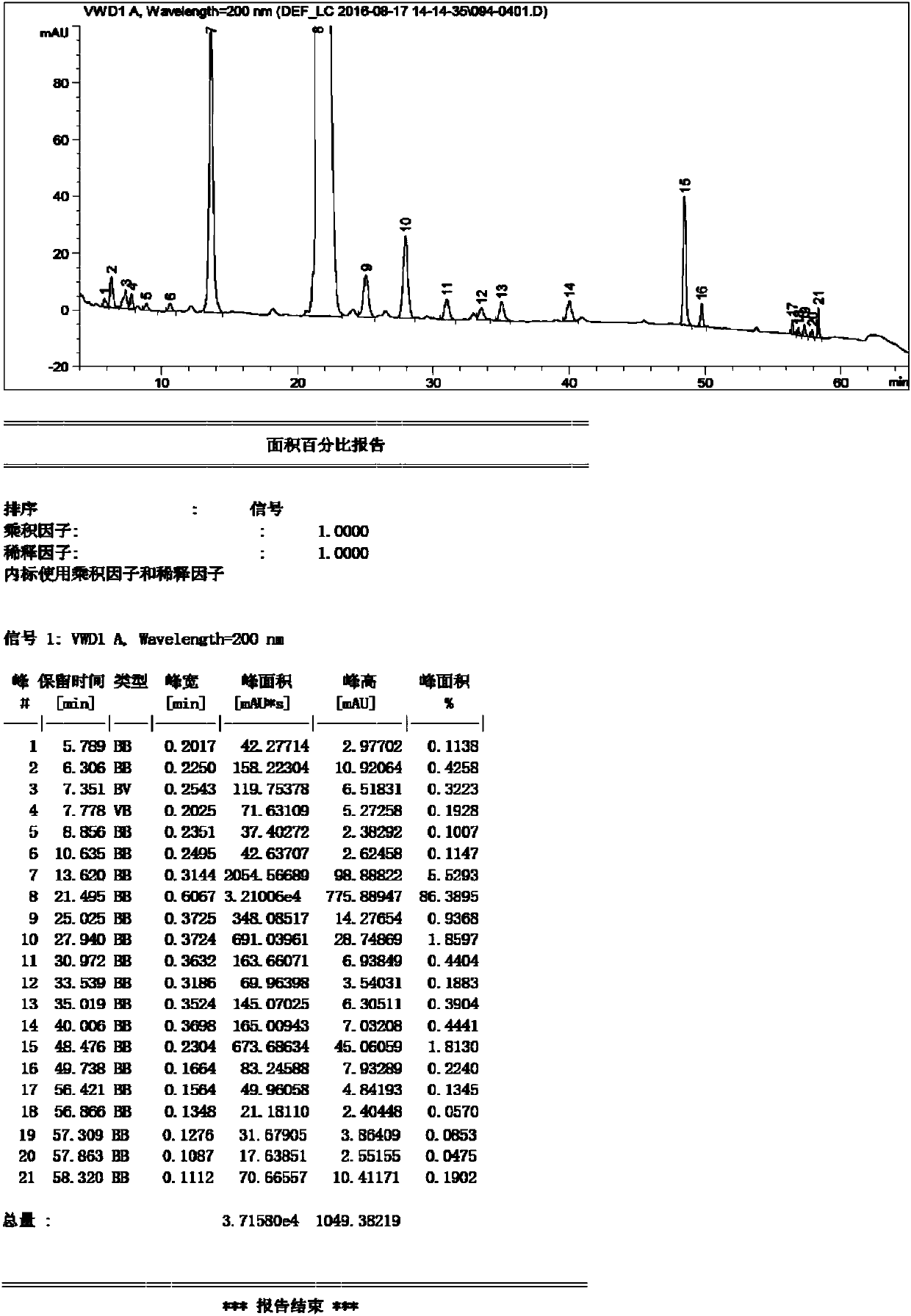

[0037]Take sugammadex sodium crude product 100g, dissolve it with 3L of water until clear, add 3g of glutathione under stirring, under the protection of nitrogen, heat up to reflux, add 8L of acetonitrile to the solution, after adding, stir and cool down to room temperature, there is A large number of white solids were precipitated, filtered by suction, and the pure product of Desugammadex Sodium was 33g, with a purity of 99.56%, see figure 2 .

Embodiment 2

[0038] Embodiment 2: Purification of sugammadex sodium

[0039] Take 100 g of sugammadex sodium crude product, dissolve it with 3 L of water until clear, add 3 g of cysteine under stirring, and raise the temperature to reflux under the protection of nitrogen, and add 8 L of acetonitrile to the solution. After the addition was completed, the temperature was cooled to room temperature with stirring, and a large amount of white solids were precipitated. After suction filtration, 35 g of pure sugammadex sodium was obtained, with a purity of 99.3%.

Embodiment 3

[0040] Embodiment 3: Purification of sugammadex sodium

[0041] Take 100 g of sugammadex sodium crude product, dissolve it with 3 L of water until clear, add 3 g of mercaptoethanol under stirring, and raise the temperature to reflux under nitrogen protection, and add 8 L of acetonitrile to the solution. After the addition was completed, the temperature was lowered to room temperature with stirring, and a large amount of white solids were precipitated. After suction filtration, 28 g of pure sugammadex sodium was obtained, with a purity of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com