Method for preparing cyclohexanol and cyclohexanone based on multi-layer annular flow guide cylinder bubbling reactor

The technology of bubbling reactor and guide tube is applied in the direction of chemical method, chemical instrument and method, and carbon-based compound preparation for reacting liquid and gas medium, which can solve the problem of excessive cyclohexane, increased material consumption, and target product. Selectivity decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

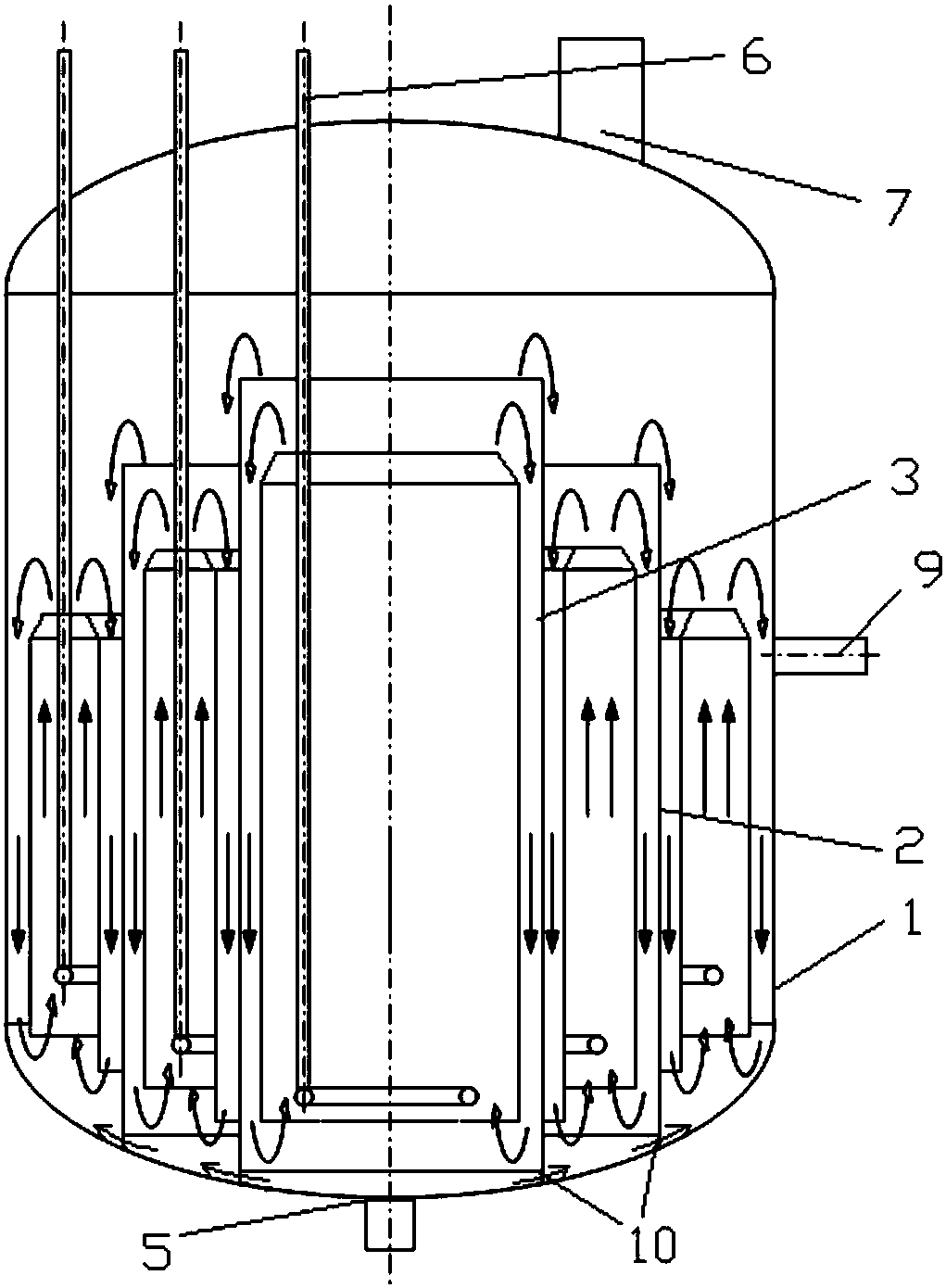

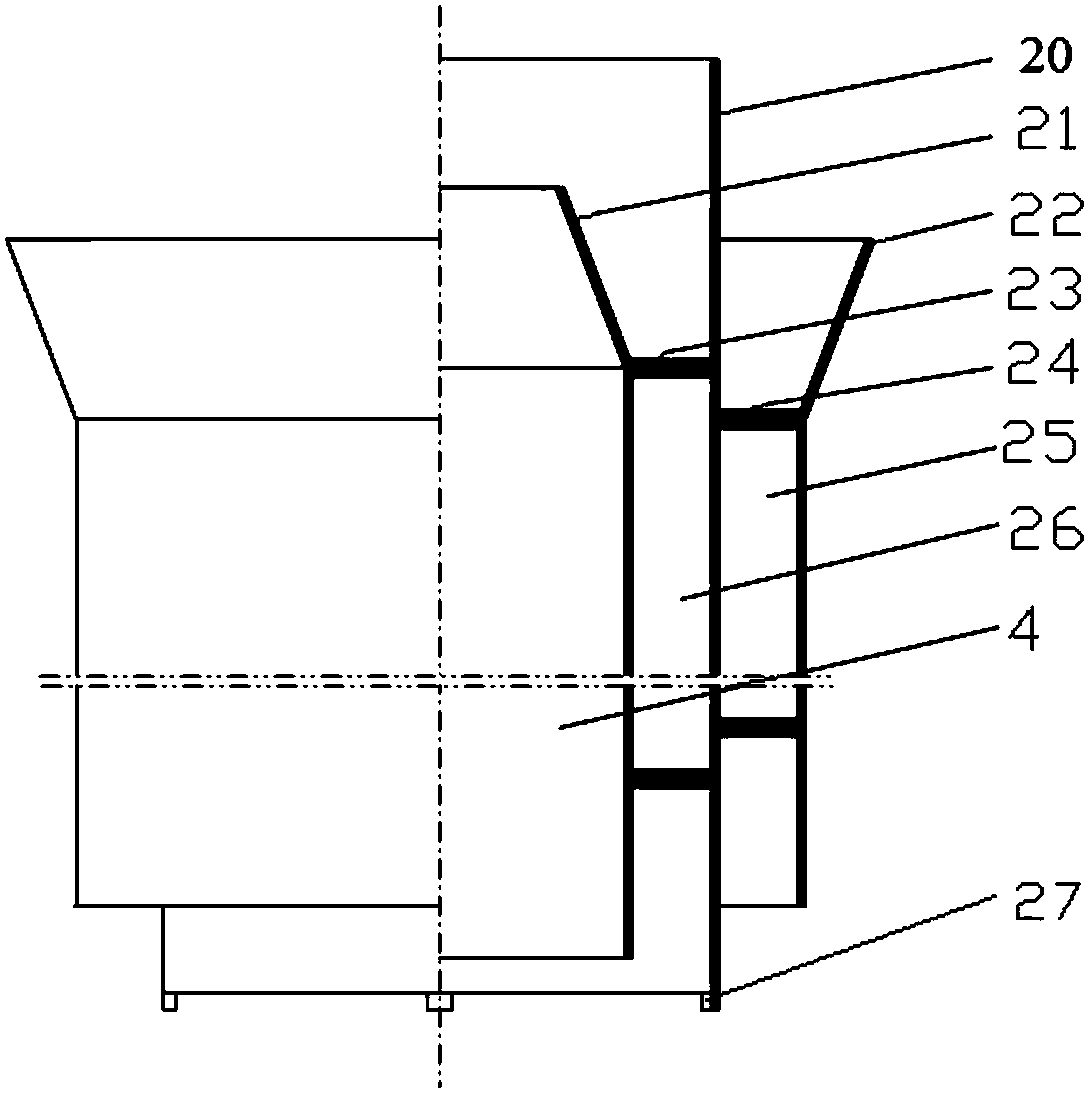

[0064] See figure 1 . The reactor shell 1 of the multi-layer double-loop flow guide tube bubble reactor is set with a multi-layer double-circle flow guide tube. In this embodiment, it is a two-layer double-loop flow guide tube, including the inner layer guide tube 3 located in the center. And the outer double-ring guide tube 2 located on the outside, the two-layer double-ring flow guide tube is coaxially arranged with the reactor shell 1, and the diameter is different, and the reactor shell 1 is divided into a three-stage annular area 4, and the double-ring The height of the flow guiding cylinder decreases step by step along the innermost double-circular flow guiding cylinder to the outermost layer of the double-circular flow guiding cylinder. There is a gap 10 between the bottom of the inner layer double-loop flow guide tube 3 and the bottom of the outer layer double-loop flow guide tube 2 and the bottom of the reactor shell 1, so that the three-stage annular area can pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com