Preparation method of hierarchical pore heteroatom aluminum phosphate molecular sieve for oxidative desulfurization

A technology of aluminum phosphate molecular sieve and heteroatom, which is applied in the direction of molecular sieve-specific aluminum phosphate, refining with halogen compounds, molecular sieve and alkali exchange phosphate, etc., which can solve the waste of internal active sites, deactivation of catalyst carbon deposition, and limit reactants and products Molecular diffusion and other problems to achieve the effect of easy recovery, high selectivity, and shortened crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example uses dynamic hydrothermal synthesis of microporous AlPO 4 -5 molecular sieves were used as crystal seeds, and hierarchically porous CoAPO-5 molecular sieves were synthesized statically and hydrothermally.

[0027] The first step, dynamic hydrothermal synthesis of AlPO 4 -5 seeds:

[0028] Hydrate 2.96g of pseudo-boehmite with 36mL of distilled water, stir magnetically at 25°C for 12h, add 4.62g of phosphoric acid solution, continue stirring for 2h, add 2.02g of microporous template agent triethylamine, and prepare molecular sieve synthetic solution, continue After stirring for 3 hours, the reactant was transferred to a dynamic hydrothermal reaction kettle, crystallized at 180°C and 500r / min for 3h, filtered with suction, washed with deionized water until neutral, dried at 110°C, and calcined at 550°C 5h, the microporous AlPO prepared by dynamic method was obtained 4 -5 molecular sieve with a particle size of 2*5μm.

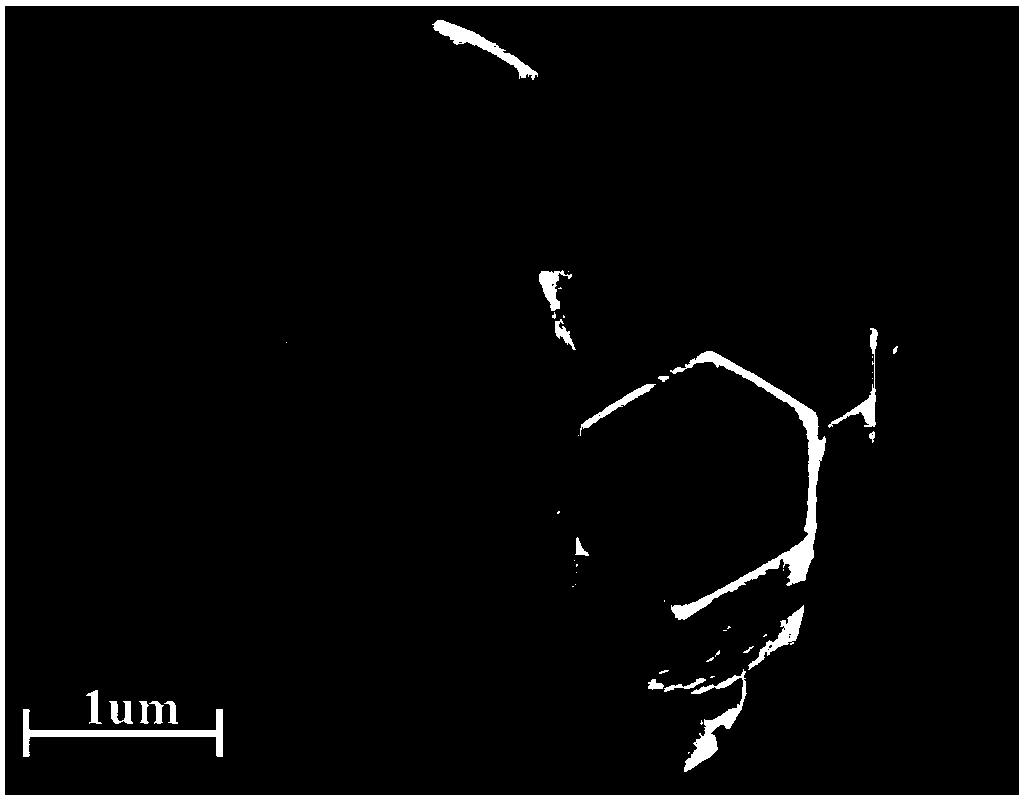

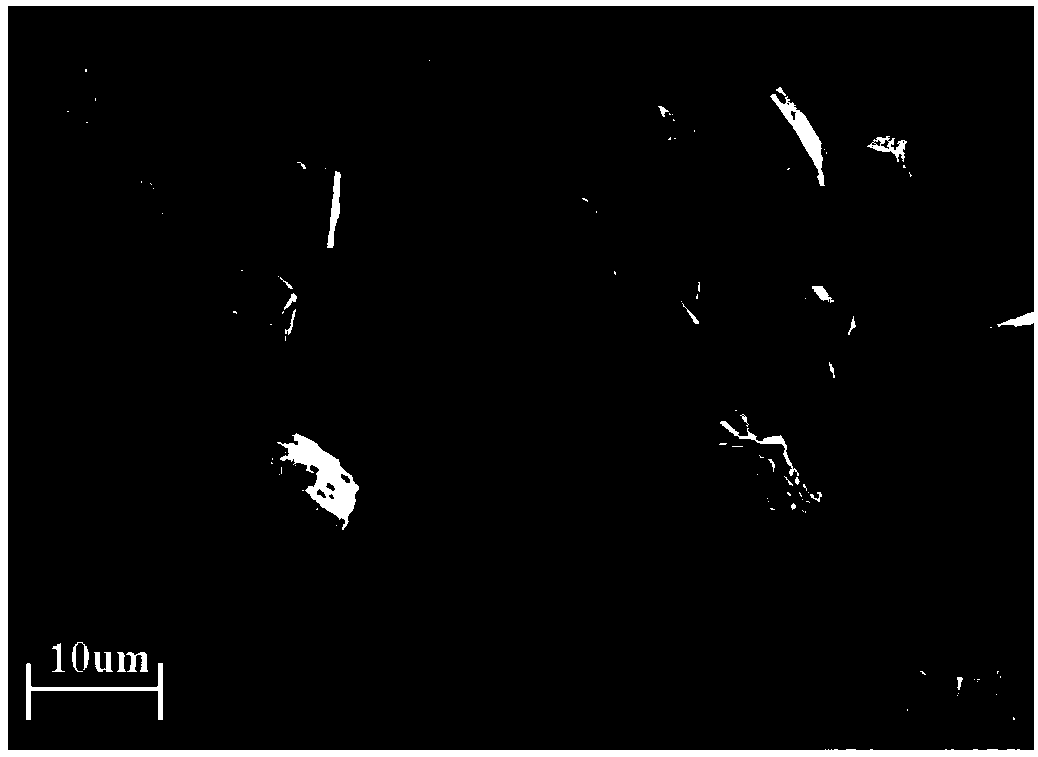

[0029] figure 2 Microporous AlPO s...

Embodiment 2

[0036] The first step, dynamic hydrothermal synthesis of AlPO 4 -5 seeds:

[0037] Hydrate 2.96g of pseudo-boehmite with 36mL of distilled water, stir magnetically at 25°C for 12h, add 4.62g of phosphoric acid solution, continue stirring for 2h, add 2.02g of triethylamine as a microporous template agent, and prepare a molecular sieve synthetic solution. After continuing to stir for 3 hours, transfer the reactant to a dynamic hydrothermal reactor, crystallize at 185°C and 400r / min for 4h, filter with suction, wash with deionized water until neutral, dry at 110°C, and dry at 550°C Calcined for 5h to obtain microporous AlPO prepared by dynamic method 4 -5 molecular sieves.

[0038] In the second step, the method of statically synthesizing the hierarchically porous CoAPO-5 molecular sieve is the same as in Example 1.

[0039] Catalytic oxidation removal of sulfide in simulated oil is the same as in Example 1, and the removal rates of thiophene, benzothiophene and dibenzothiophe...

Embodiment 3

[0041] The first step, dynamic hydrothermal synthesis of AlPO 4 -5 seeds:

[0042] Hydrate 2.96g of pseudo-boehmite with 36mL of distilled water, stir magnetically at 25°C for 12h, add 4.62g of phosphoric acid solution, continue stirring for 2h, add 2.02g of triethylamine as a microporous template agent, and prepare a molecular sieve synthetic solution. After continuing to stir for 3 hours, transfer the reactant to a dynamic hydrothermal reaction kettle, crystallize at 160°C and 500r / min for 3h, filter with suction, wash with deionized water until neutral, dry at 110°C, and dry at 550°C Calcined for 5h to obtain microporous AlPO prepared by dynamic method 4 -5 molecular sieves.

[0043] The second step of static synthesis of hierarchically porous CoAPO-5 molecular sieves is the same as in Example 1.

[0044] Catalytic oxidation removal of sulfide in simulated oil is the same as in Example 1, and the removal rates of thiophene, benzothiophene, and dibenzothiophene are 69.25%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com