Material in and out device used for gelatin cooking machine

A technology for loading and unloading materials and rubber machines, which is applied in the direction of cranes, transportation and packaging, and trolley cranes, etc. It can solve problems such as operational errors, potential safety hazards for operators, and corrosion of circuits, so as to increase reliability, reduce the impact of devices, and guarantee The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

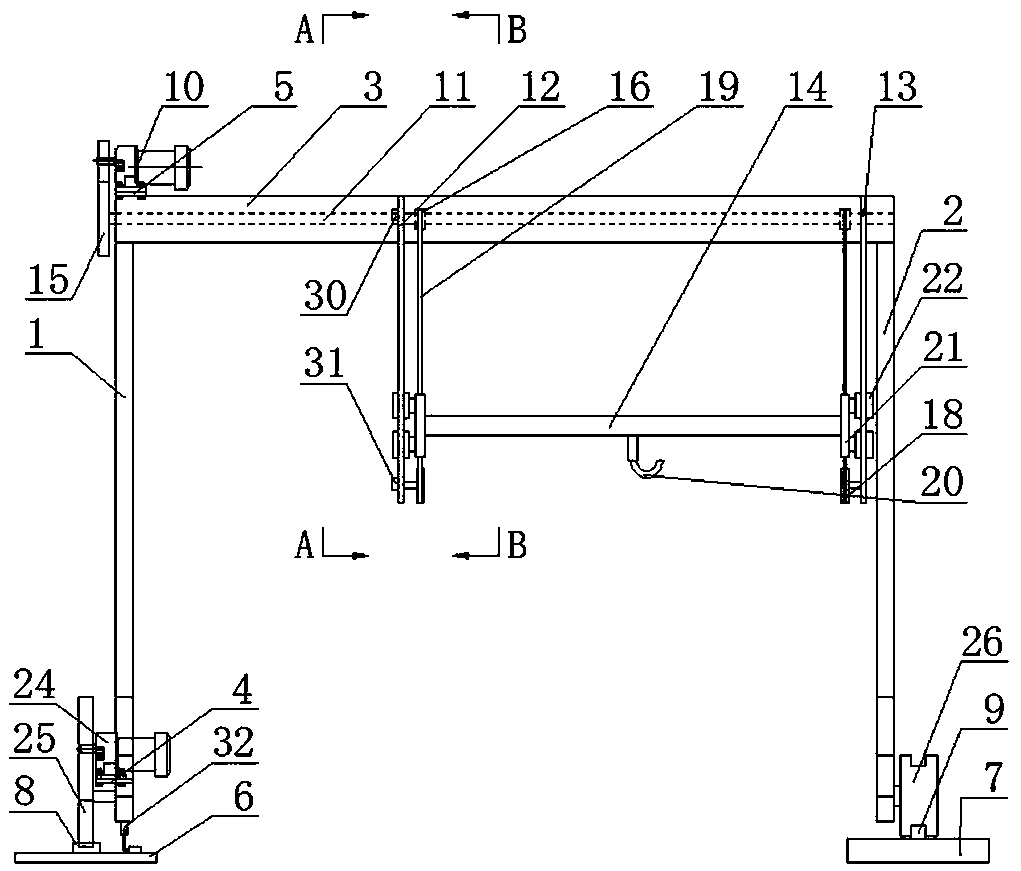

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1~Figure 5 As shown, a feeding and discharging device for a glue cooking machine includes a frame body and a track under the frame body, and also includes a lifting mechanism on the upper part of the frame body and a walking mechanism on the lower part of the frame body;

[0029] The frame body includes a first column 1, a second column 2, and a crossbeam 3 fixedly connected to the top of the first column 1 and the second column 2. The first column 1 and the second column 2 are herringbone-shaped, and the first column 1 The lower part is provided with a first motor seat 4, the beam 3 is a hollow square tube, and the upper surface of one end of the beam 3 is welded with a second motor seat 5;

[0030] The track comprises a first track 6 and a second track 7 respectively positioned below the first column 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com