Dual-wall permanent floating ship

A technology for pontoons and hulls, which is applied in the direction of hulls, hull bulkheads, and hull components. It can solve the problems of not being able to ensure the safety of the ship and everyone on board, not being able to adjust the tilting in a timely and effective manner, and not being able to effectively lower the center of gravity. Dead angle shipwreck, good stability and strong wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

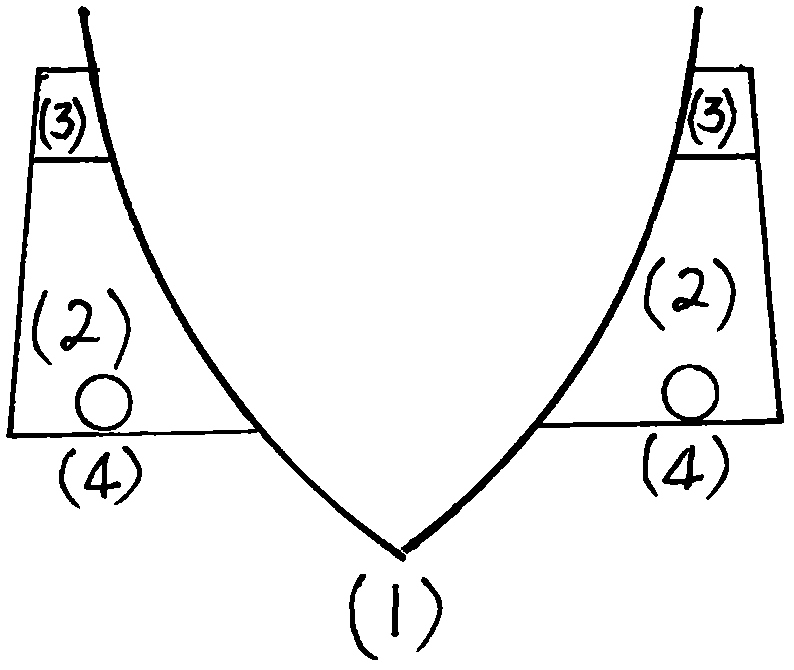

[0021] 1. Make the boat into a pointed bottom. The two side walls of the underwater part of the hull are that two garden arcs intersect and point downwards to form a sharp-bottomed ship (1), and the cross section looks like a V font.

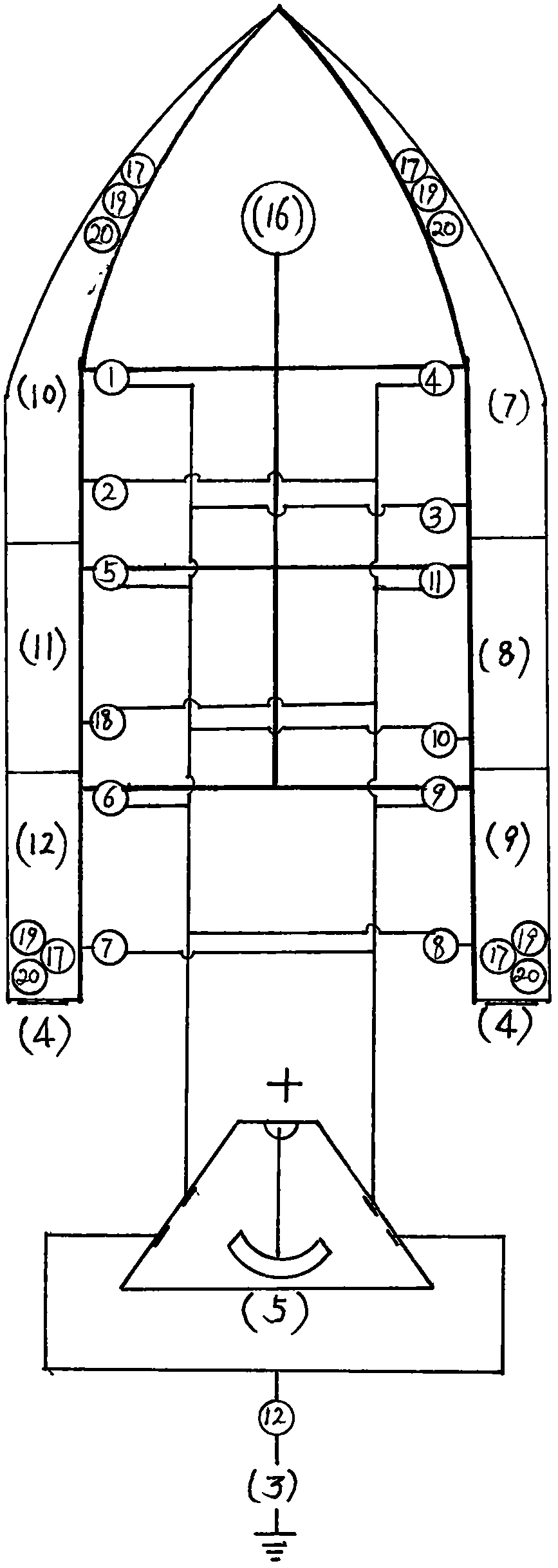

[0022] 2. Add a layer of side walls on both side walls of the hull (the bottom is inclined outwards) to form a platform-shaped airtight and hollow box (2). The top of the box is higher than the water level, and the bottom is slightly higher than the bottom. A large-diameter long-axis electric butterfly valve (4) is installed at the bottom of the rear side wall of the tail. The butterfly valve is in a fully open state and communicates with the outside water at ordinary times, so that water can enter and exit freely. Both sides casings are symmetrically divided into independent airtight front cabins (7), (10), middle cabins (8), (11), rear cabins (9), (12) six cabins (in order to prevent individual cabins from being hit) In case of air leakage, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com