Novel dihydrogen bond deep-eutectic solvent and method for pretreating rice straws through combination of solvent and sodium carbonate

A deep eutectic solvent and pretreatment technology, applied in the field of chemical engineering, can solve the problems of high price, low toxicity and biodegradability, and achieve the effect of low cost, low cost and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 The synthesis of double hydrogen bond deep eutectic solvent

[0015] Accurately weigh 100g of different molar ratios of choline chloride: formic acid: acetic acid (1:0.5:0.5~2:1.5:1.5) into a three-neck flask for mixing, and stir the reaction at 60°C for 2 hours. At this time, a uniform, clear and transparent of liquid. The liquid is transferred into a round-bottomed flask, and incompletely reacted formic acid and acetic acid are removed by distillation under reduced pressure, finally obtaining choline chloride of different proportions: formic acid: acetic acid deep eutectic solvent. 10 g of rice straw was weighed and added to the solvent, stirred at 140° C. for 2 h, then the mixture was centrifuged, the precipitate was washed with deionized water three times, and dried to a constant weight. Weigh 1g of the treated straw, add 10mL pH 4.8, 50mM citric acid-sodium citrate buffer, continue to add 50FPU cellulase ( 1500), 50° C. and 150 rpm for 24 h on a sha...

Embodiment 2

[0018] Example 2 Double hydrogen bond deep eutectic solvent pretreatment of rice straw

[0019] Measure 100g of choline chloride: formic acid: acetic acid deep eutectic solvent to a three-necked flask, weigh 5 to 20g of rice straw (the mass ratio of solvent to rice straw is 5:1 to 20:1) and add it to the solvent, Stir at 140°C for 0.5-3 hours, then centrifuge the mixture, wash the precipitate with deionized water three times, and dry to constant weight. Weigh 1g of the treated straw, add 10mL pH4.8, 50mM citric acid-sodium citrate buffer, continue to add 30-70FPU cellulase ( 1500), 50° C. and 150 rpm for 24 h on a shaker in a water bath. Glucose, xylose and arabinose in the hydrolyzate were determined by high performance liquid chromatography, as shown in Table 2. During the pretreatment process, with the increase of straw addition, the content of total sugar after pretreatment gradually increased. In view of the highest utilization efficiency of ionic liquid and straw, 10...

Embodiment 3

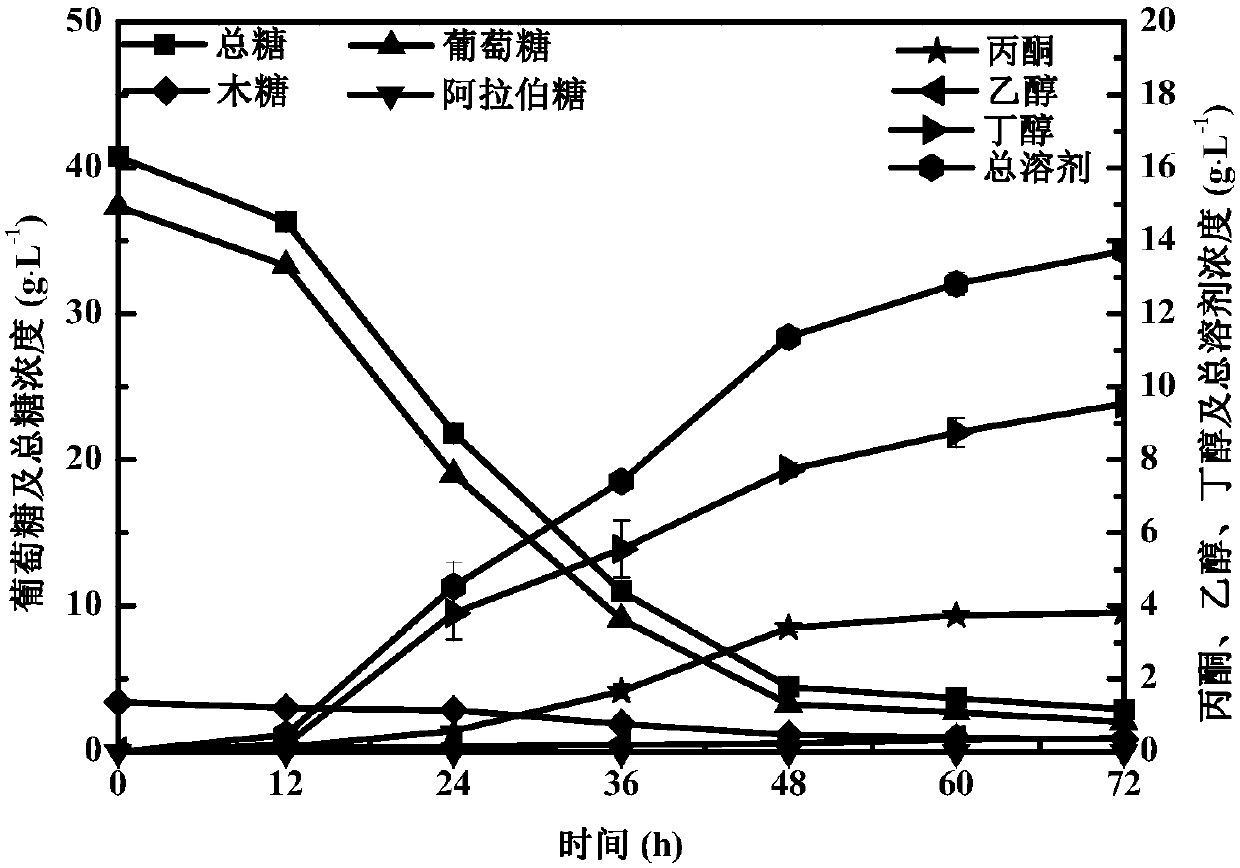

[0023] Example 3 Combined double hydrogen bond deep eutectic solvent and sodium carbonate pretreatment of rice straw

[0024] Accurately weigh 10 g of the rice straw pretreated by the double hydrogen bond deep eutectic solvent in Example 2, add 0-10% sodium carbonate solution, treat at 60-140°C for 0.5-3h, then centrifuge the mixture, and use The precipitate was washed three times with deionized water and dried to constant weight. Weigh 1g of the treated straw, add 10mL pH 4.8, 50mM citric acid-sodium citrate buffer, continue to add 50FPU cellulase ( 1500), 50° C. and 150 rpm for 24 h on a shaker in a water bath. Glucose, xylose and arabinose in the hydrolyzate were determined by high performance liquid chromatography, as shown in Table 3. The total sugar content of 0.5% sodium carbonate solution after pretreatment at 140°C for 1 hour has reached 43.13g / L. In view of the environmental protection of the pretreatment reagent, 0.5% sodium carbonate was selected as the combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com