Mullite-based castable used for tundish cover and production method thereof

A production method and technology of mullite, applied in the field of refractory unshaped refractory products, can solve the problems of thermal shock stability constraints of the cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

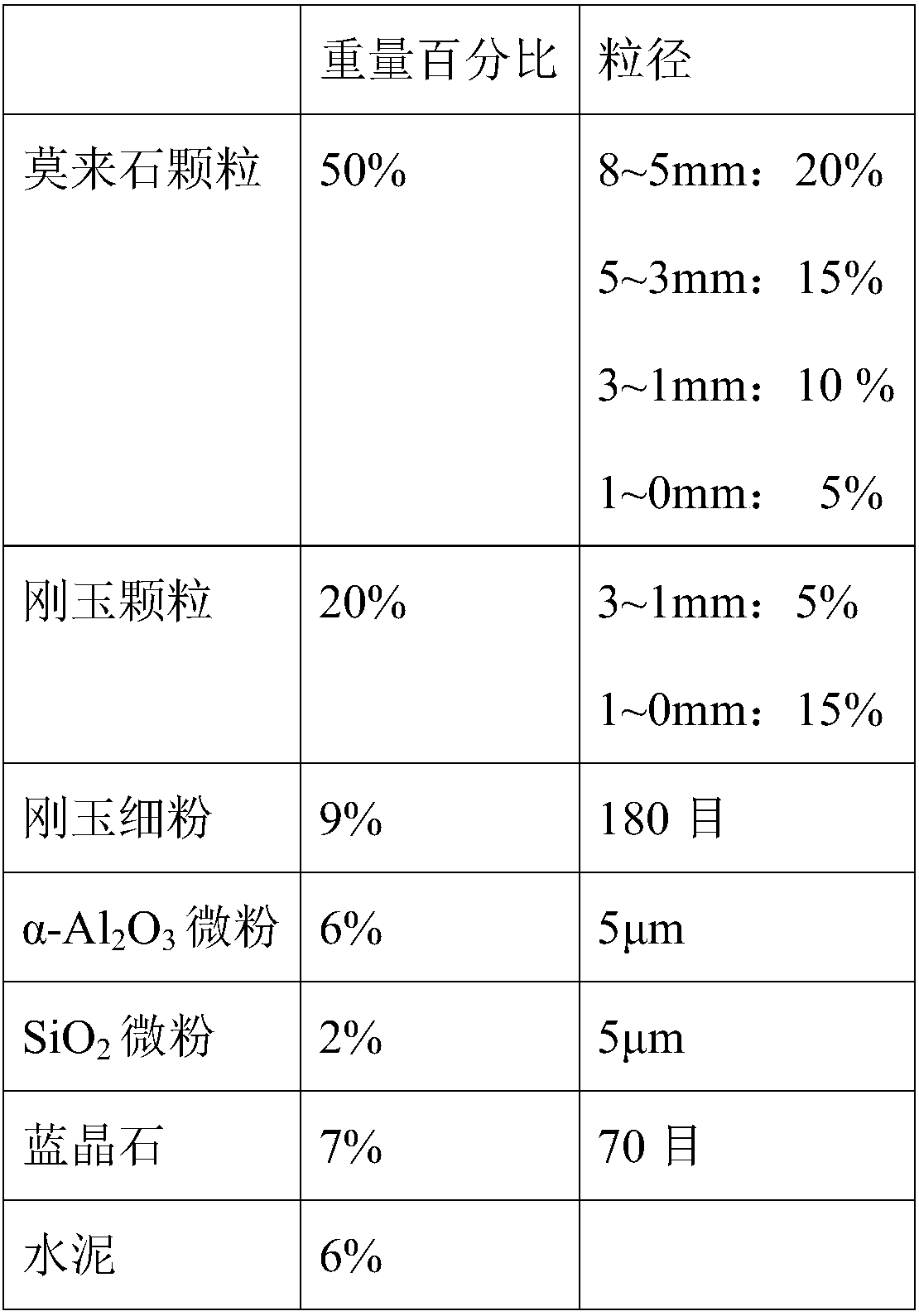

Embodiment 1

[0028] A mullite castable for a tundish cover, the mullite castable for a tundish cover is prepared from a main material and an additive, and the weight percentage of the main material is shown in Table 1. Described admixture comprises 446# steel fiber, ADS 1 Water reducing agent, ADW 1 Water reducer, aluminum powder, organic explosion-proof fiber and water, the weight percentages of each component in the main material are: 446# steel fiber 2%, ADS 1 Water reducer 0.8%, ADW 1 0.4% water reducing agent, 0.25% aluminum powder, 0.15% organic explosion-proof fiber and 6.0% water.

[0029] Its preparation method is as follows:

[0030] (1) Premixing: corundum fine powder, α-Al 2 o 3 Micropowder, SiO 2 Micropowder, kyanite, cement and half of the admixture are premixed;

[0031] (2) Mixing and grinding: Mix and grind mullite particles and corundum particles, add the other half of the admixture for mixing and grinding, then add the premix obtained in step (1) and mix and grind...

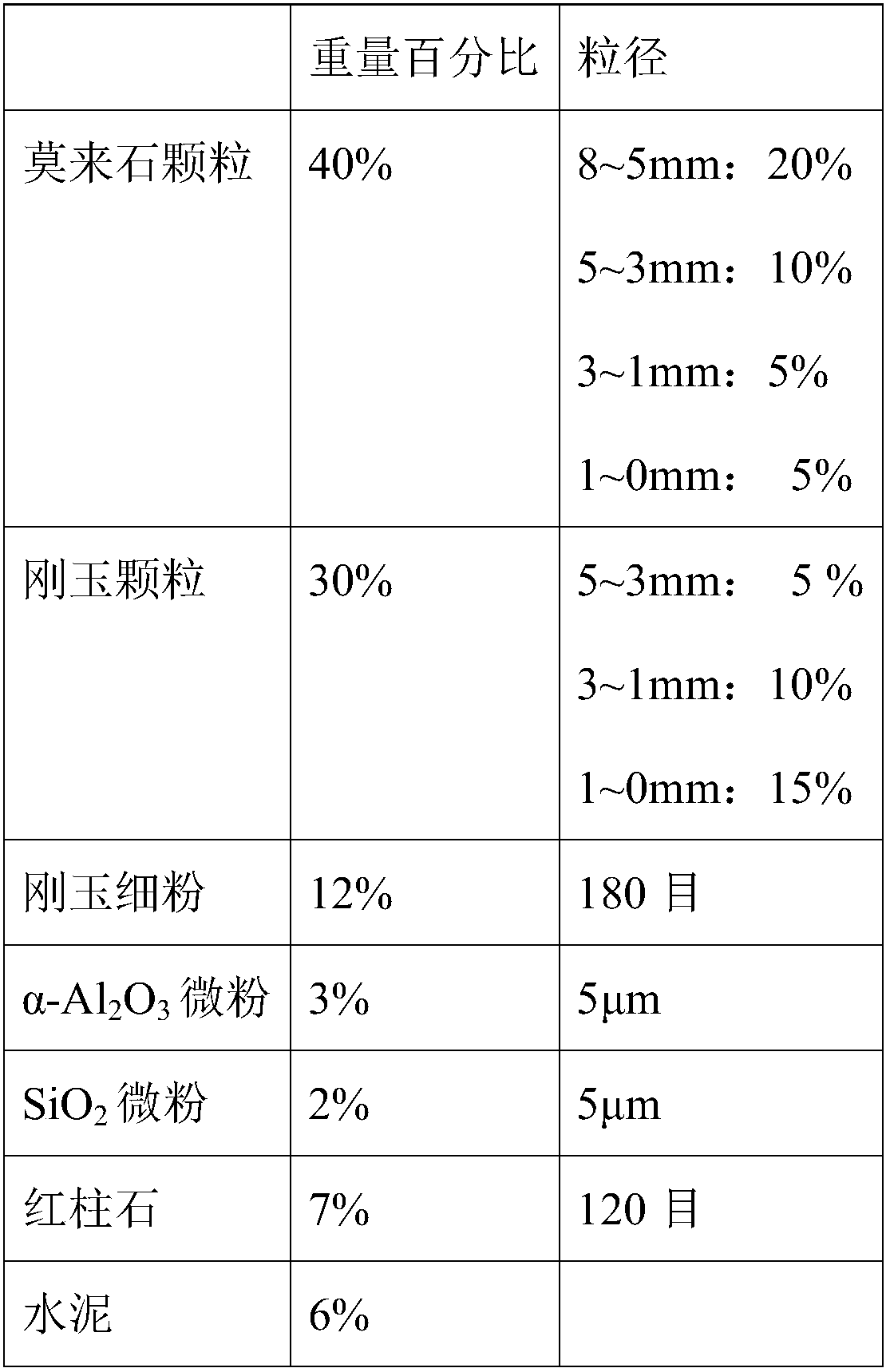

Embodiment 2

[0039] A mullite castable for the tundish cover, the mullite castable for the tundish cover is prepared from a main material and an additive, and the weight percentage of the main material is shown in Table 2. Described admixture comprises 446# steel fiber, ADS 1 Water reducing agent, ADW 1 Water reducer, aluminum powder, organic explosion-proof fiber and water, the weight percentages of each component in the main ingredients are: 446# steel fiber 1%, ADS 1 Water reducer 1.0%, ADW 1 1.0% water reducing agent, 0.10% aluminum powder, 0.40% organic explosion-proof fiber and 6.5% water. Its preparation method is with embodiment 1.

[0040] Raw materials and parts by weight contained in the main ingredients of table 2

[0041]

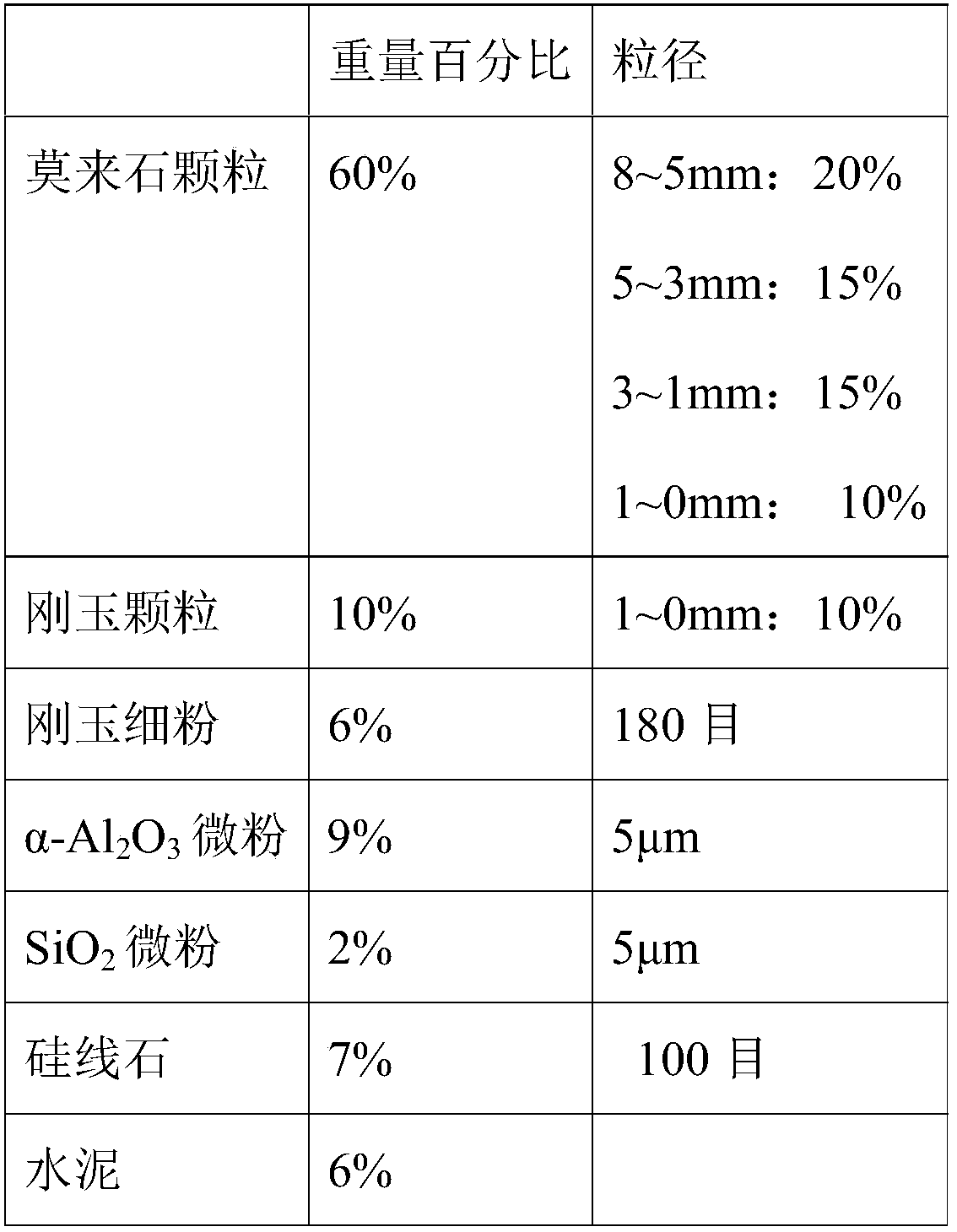

Embodiment 3

[0043] A mullite castable for the tundish cover. The mullite castable for the tundish cover is prepared from main ingredients and additives. The weight percentage of the main ingredients is shown in Table 3. Described admixture comprises 446# steel fiber, ADS 1 Water reducing agent, ADW 1 Water reducer, aluminum powder, organic explosion-proof fiber and water, the weight percentages of each component in the main material are: 446# steel fiber 3%, ADS 1 Water reducer 0.5%, ADW1 0.1% water reducing agent, 0.50% aluminum powder, 0.05% organic explosion-proof fiber and 6.2% water. Its preparation method is with embodiment 1.

[0044] Raw materials and parts by weight contained in the main ingredients of table 3

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com