Automatic stamping system and method for cylinder part with automatic unloading function

A technology for automatic unloading and cylindrical parts, which is applied in the field of mechanical processing and stamping manufacturing, can solve the problems of complex process and low production efficiency of non-standard stainless steel cylinders, and achieve the effect of ensuring quality and solving inconvenient unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

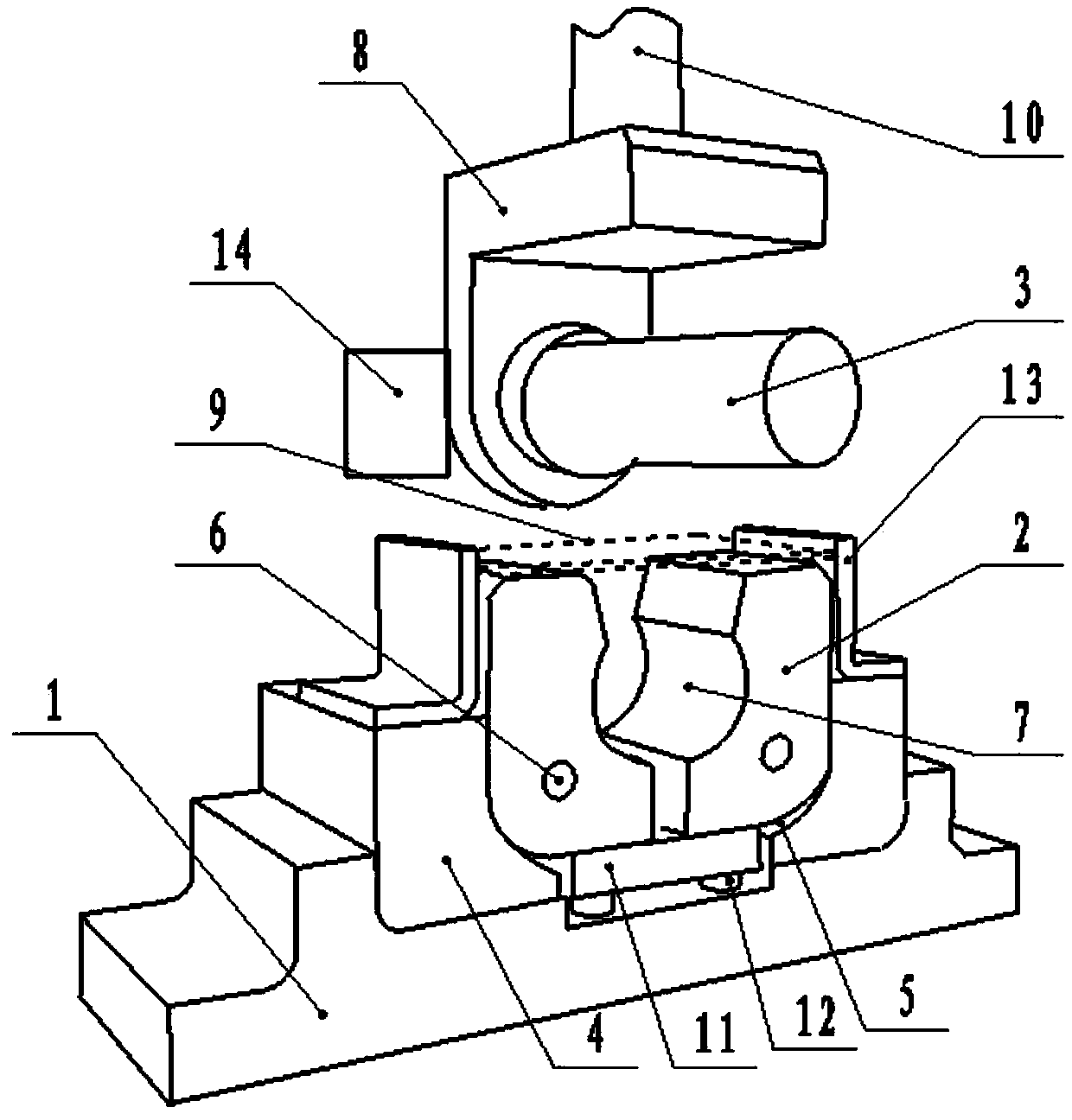

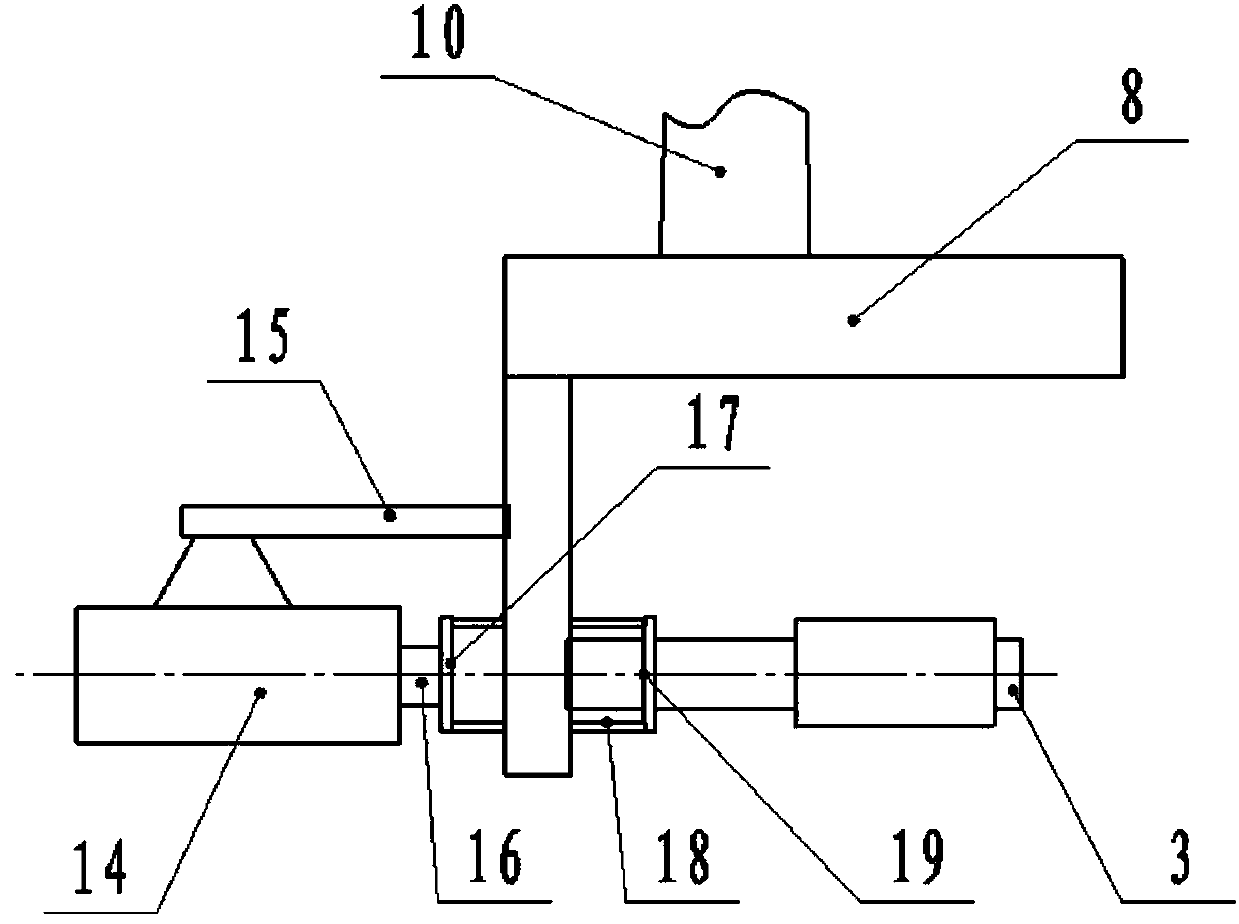

[0033] Such as Figure 1-2 As shown, an automatic stamping system for cylindrical parts with automatic unloading function of the present invention includes a stamping base 1, a stamping female module 2 and a stamping male die rod 3, and two stamping limit blocks 4 are symmetrically arranged on the stamping base 1 , the inner surface of the stamping limit block 4 is provided with a limit arc surface 5, and the two stamping female modules 2 are correspondingly arranged on the limit arc surfaces 5 of the two stamping limit blocks 4 through the limit shaft 6, and the stamping The inner surface of the mother module 2 is provided with an arc surface 7 matching the outer circle size of the stamping cylinder;

[0034] The stamping male die rod 3 is horizontally arranged on the corresponding top of the stamping base 1 and connected with the stamping block 8, and the rear side of the stamping block 8 corresponding to the stamping male die rod 3 is provided with a discharge cylinder 14, ...

Embodiment 2

[0042] Such as Figure 1-2 As shown, a kind of automatic stamping method of stainless steel cylindrical part of the present invention comprises steps:

[0043] Step 1) Place the cut stamping plate 9 between two L-shaped stamping plate stoppers;

[0044] Step 2) Then start the stamping bed to drive the stamping arm 10 to stamp downward, and the stamping arm 10 drives the stamping male die rod 3 to stamp the stamping plate 9;

[0045] Step 3) Punching the male mold rod 3 by putting the stamping plate 9 into the two stamping female modules 2 to form a cylindrical mold, and under the stamping action of the stamping male mold rod 3, the stamping female module 2 rotates around the limit shaft 6;

[0046] Step 4) When the upper end faces of the two stamped female modules 2 are connected, the stamped plate 9 is stamped into a cylindrical piece.

[0047] Also includes step 5) the stamped cylindrical piece, after the stamping block 8 is lifted in place, the unloading cylinder 14 pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com