Preparation method of spherical mesoporous carbon-loaded noble metal catalyst

A noble metal catalyst and noble metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of low catalytic performance of noble metal, poor dispersion effect of noble metal, preparation process Complicated problems, to achieve good economic benefits, easy promotion, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

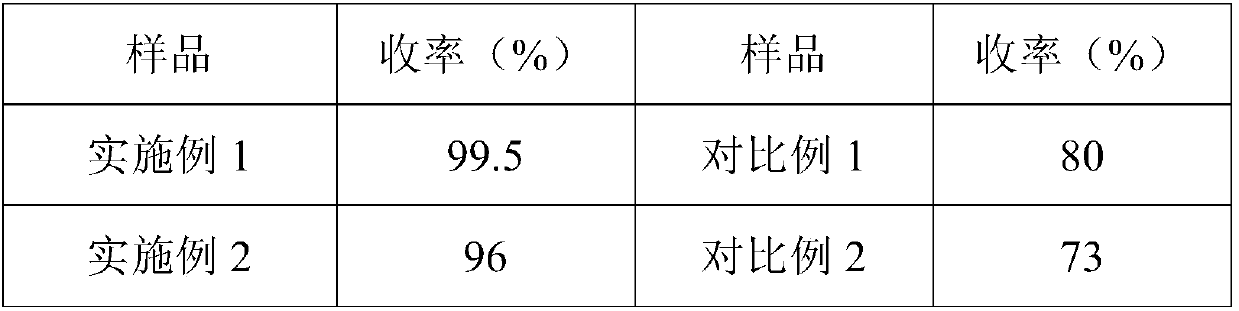

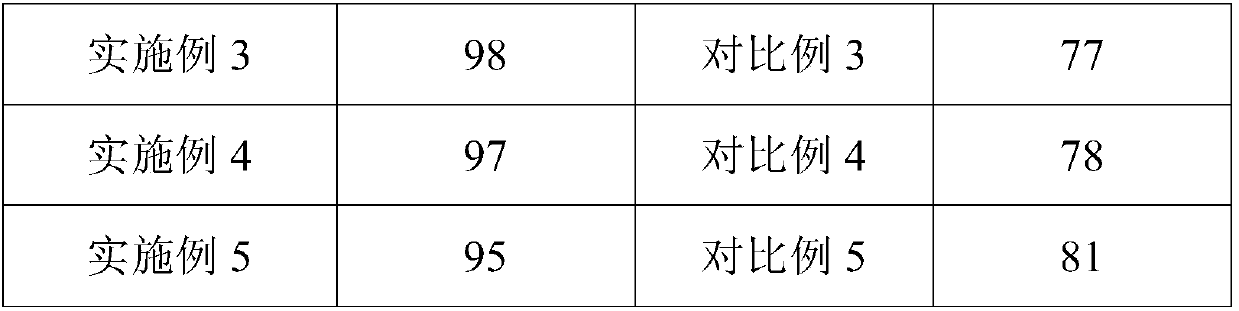

Examples

Embodiment 1

[0045] (1) Spherical mesoporous carbon is prepared by reverse-phase suspension polymerization, and the specific surface area and pore diameter of mesoporous carbon are controlled by adjusting the amount of dispersant added in the suspension polymerization method, and the specific surface area is screened at 400-600m 2 / g, mesoporous carbon with a pore size between 7.5-9.5nm;

[0046] (2) Add the salt solution containing noble metal platinum into the nitric acid solution with a concentration of 5mol / L, heat and stir to obtain the impregnation solution, the heating temperature is 50°C, the stirring time is 5h, and the mass ratio of noble metal to mesoporous carbon is 0.4: 1;

[0047] (3) Using the equal volume impregnation method, impregnate the mesoporous carbon in the above impregnation solution, heat and stir, the heating temperature is 70°C, and the stirring time is 3h. After adjusting the pH value to 4-5, continue to stir at constant temperature and supplement it with ultra...

Embodiment 2

[0051] (1) Spherical mesoporous carbon is prepared by the hard template method, and the specific surface area and pore diameter of the mesoporous carbon are controlled by adjusting the amount of carbon source added in the template method, and the specific surface area is screened at 400-600m 2 / g, mesoporous carbon with a pore size between 7.5-9.5nm;

[0052] (2) Add the salt solution containing noble metal palladium into the hydrochloric acid solution with a concentration of 0.5mol / L, heat and stir to obtain the impregnation solution, the heating temperature is 50°C, the stirring time is 5h, and the mass ratio of noble metal to mesoporous carbon is 0.35 :1;

[0053] (3) Using the excessive impregnation method, impregnate the mesoporous carbon in the above impregnation solution, heat and stir, the heating temperature is 65°C, and the stirring time is 2h. After adjusting the pH value to 4-5, continue to stir at constant temperature and supplemented by ultrasonic vibration for 1...

Embodiment 3

[0057] (1) Spherical mesoporous carbon is prepared by reverse-phase suspension polymerization, and the specific surface area and pore diameter of mesoporous carbon are controlled by adjusting the amount of dispersant added in the suspension polymerization method, and the specific surface area is screened at 400-600m 2 / g, mesoporous carbon with a pore size between 7.5-9.5nm;

[0058] (2) Add the salt solution containing the precious metal rhodium into the sulfuric acid solution with a concentration of 8mol / L, heat and stir to obtain the impregnation solution, the heating temperature is 60°C, the stirring time is 6h, and the mass ratio of the precious metal to the mesoporous carbon is 0.45:1 ;

[0059] (3) Using the equal volume impregnation method, impregnate the mesoporous carbon in the above impregnation solution, heat and stir, the heating temperature is 80°C, and the stirring time is 4h. After adjusting the pH value to 4-5, continue to stir at constant temperature and supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com