Filter element blowback device for automatic sand blasting derusting device

A technology of sandblasting and rust removal and filter elements, which is applied in the processing of used abrasives, transportation and packaging, and filtration of dispersed particles. It can solve the problems of poor rust and dust blow-off effect on the filter elements and difficult internal blowback of the filter elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

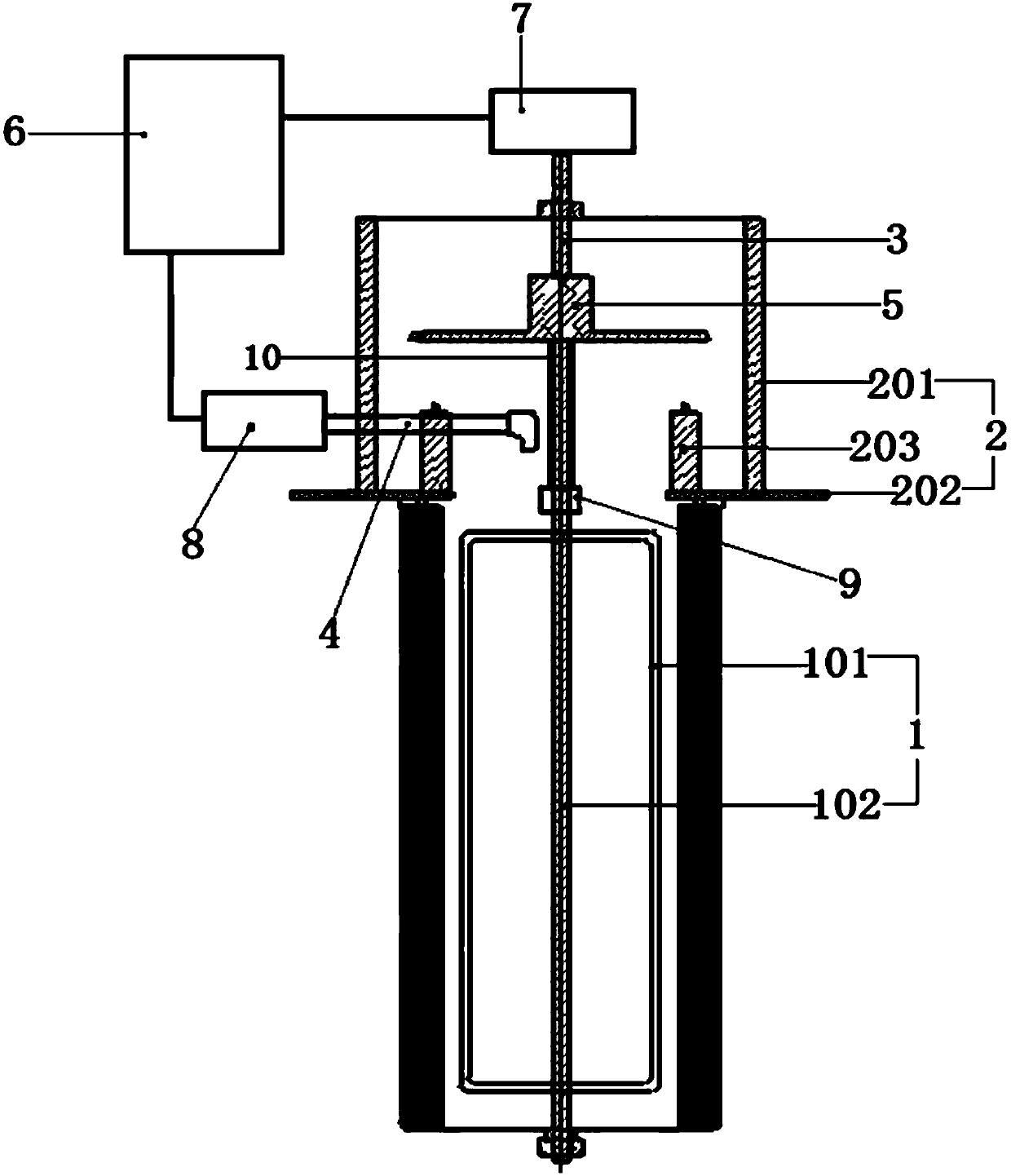

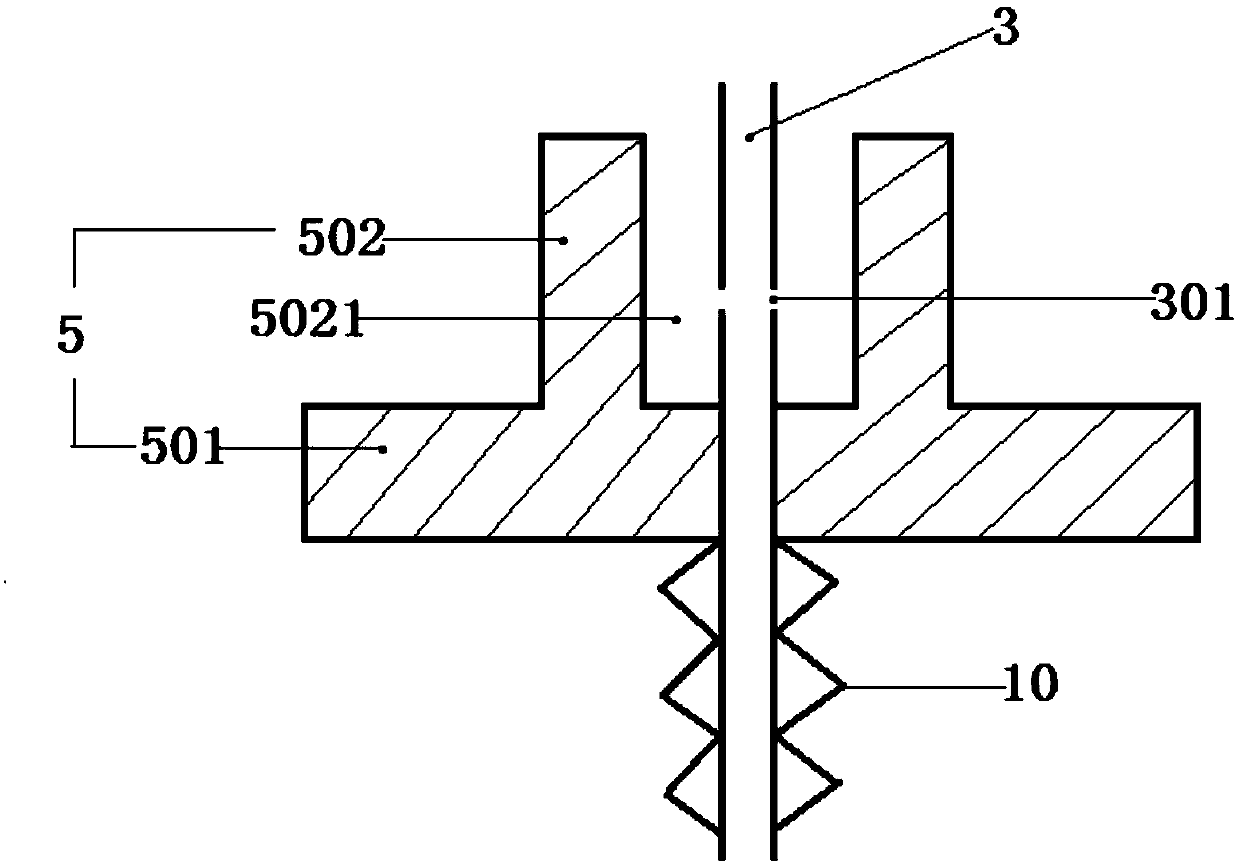

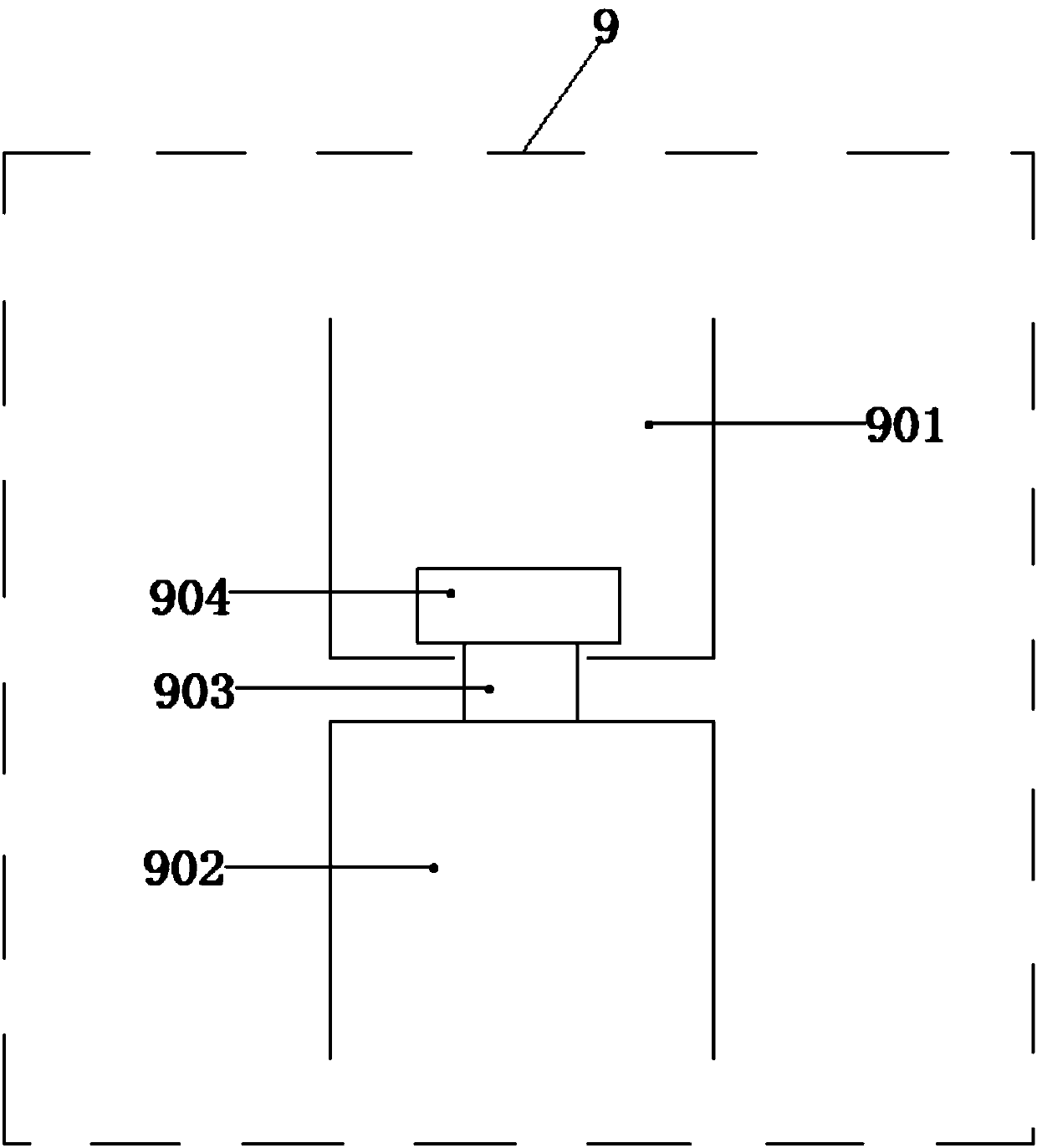

[0059] The embodiment of the present invention provides a filter element blowback device for automatic sand blasting and derusting device, as attached figure 1As shown, the filter element blowback device includes a blowback rotor assembly 1, a bracket 2, an air intake pipe 3, a blast blowback pipe 4, a sealing plate 5, a blowback air storage tank 6, a first pulse valve 7 and a second pulse valve 8 . Wherein, the blowback rotor assembly 1 comprises a zigzag tube 101 and a vertical tube 102 with a closed lower end, the vertical tube 102 is fixed and communicated with the middle part of the upper horizontal tube and the lower horizontal tube in the zigzag tube 101, and the zigzag tube 101 The walls of the left vertical tube and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com