Drilling and grouting construction method for sand gravel stratum

A technology of sand and gravel and stratum, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of low construction efficiency, difficult operation, affecting the grouting effect, etc., and achieve the effect of simplifying the difficulty of installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

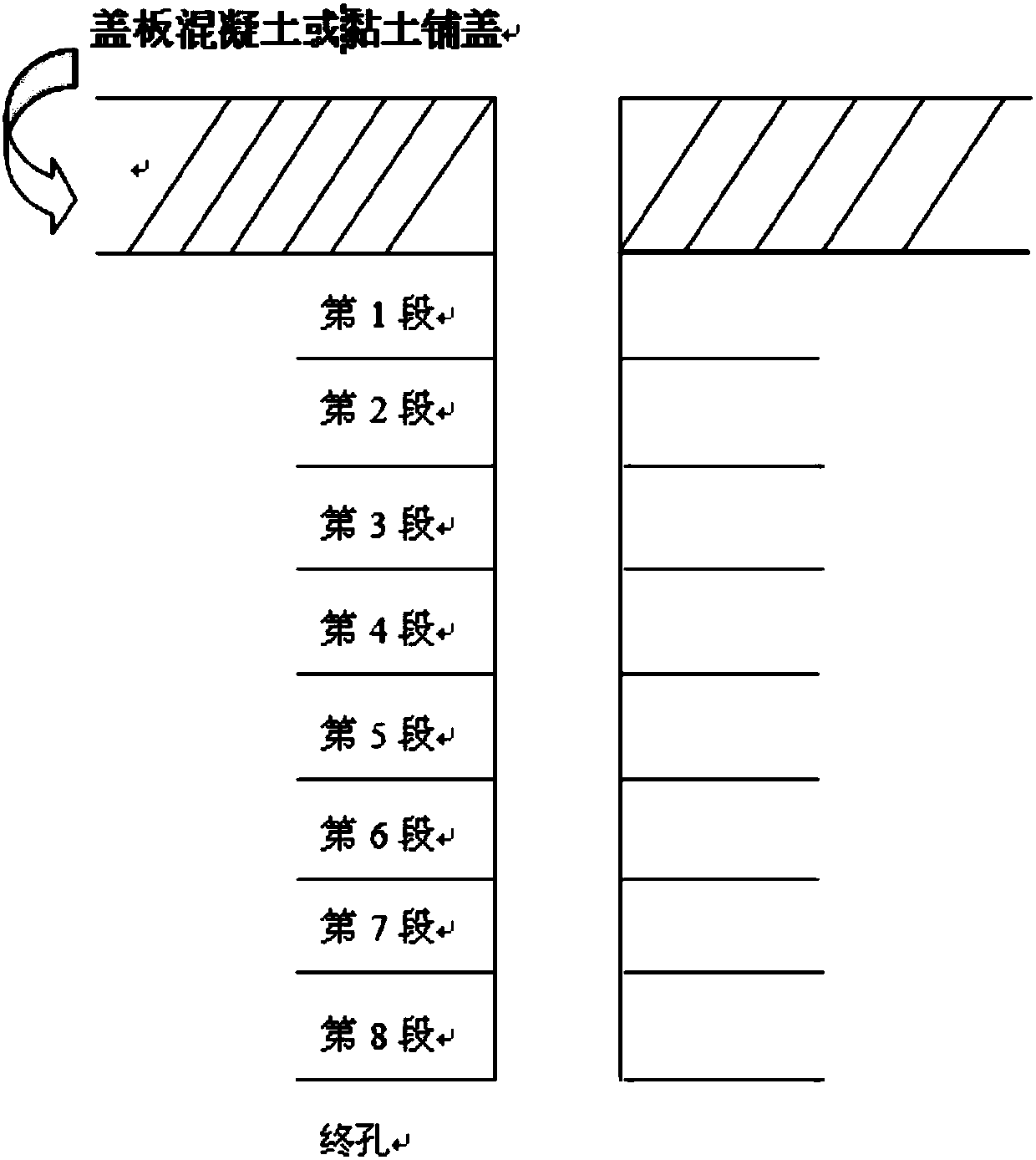

[0064] like figure 1 As shown, the method includes:

[0065] (1) After drilling to the specified depth, follow the pipe to drill into the wall casing; or first use the pipe to drill to send the wall casing to the predetermined depth, and then use the coring method to remove the sand and gravel in the pipe. Until the casing is down to the depth of the grouting segment.

[0066] (2) After the drilling and casing construction is completed, flush the drilling hole, lower the grouting pipe, and pull the bottom of the casing to the top of the grouting section. Rigid plastic tube with floral tube and wrapped with non-woven fabric, the set section length is 5m.

[0067] (3) Install an orifice blocker on the upper part of the grouting pipeline, that is, insert the rubber ring with a hole in the center into a 1.0m double-layer grouting pipe with a bottom support. The diameter of the outer pipe is 50mm, and the diameter of the inner pipe is the same as that of the grouting pipeline. T...

Embodiment

[0079] The strata in a certain place are Quaternary alluvium (alQ4) clay, silt and gravel from top to bottom, and the underlying bedrock is the Lower Tertiary Xinyu Group (E1-2xn) composite conglomerate and gravel strata It is medium or above dense formation, 2-4cm gravels account for 65%, other fillers account for 35%, and the maximum particle size is 6-8cm. When the water level was stored at an elevation of 46.5m, a bubble spring with a diameter of about 5-8cm appeared behind the embankment, and a large area was flooded. For this reason, it is decided to take grouting measures to reinforce the gravel strata where the design spacing of pendulum spraying is 1.4m.

[0080] During the sand and gravel foundation grouting construction process, through the sand and gravel stratum technology test, it was found that: 1) when the method of inserting flower tubes was adopted for construction, the grouting channel was blocked by the fine sand entering the flower tube, so that the sand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com