Straw decomposition furnace for fermentation

A calcining furnace and straw technology, which is applied in bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, biochemical instruments, etc., can solve the problems of unfavorable subsequent fermentation, poor pulverization effect, etc., and achieve good pulverization effect. , the effect of improving the crushing effect and improving the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

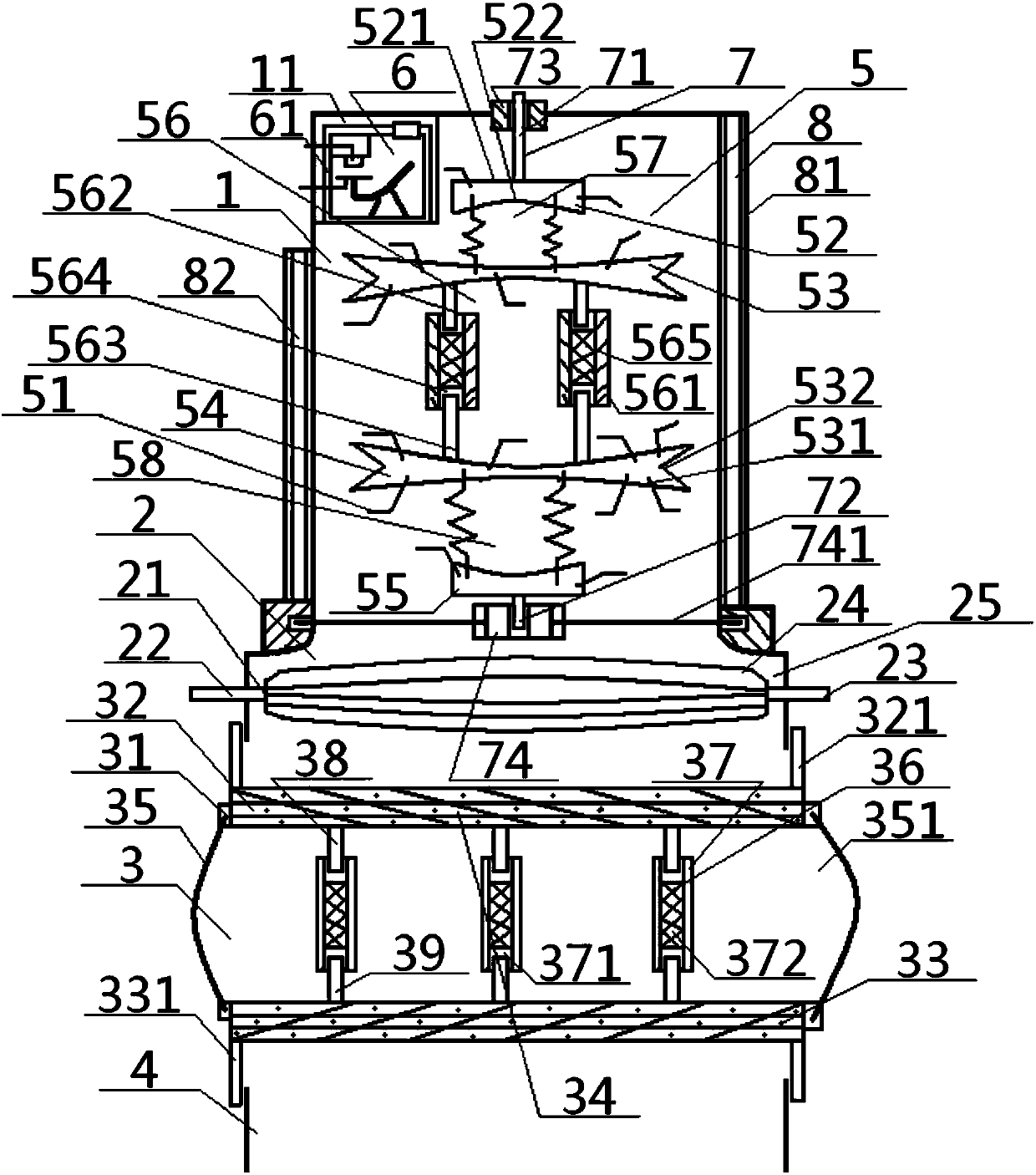

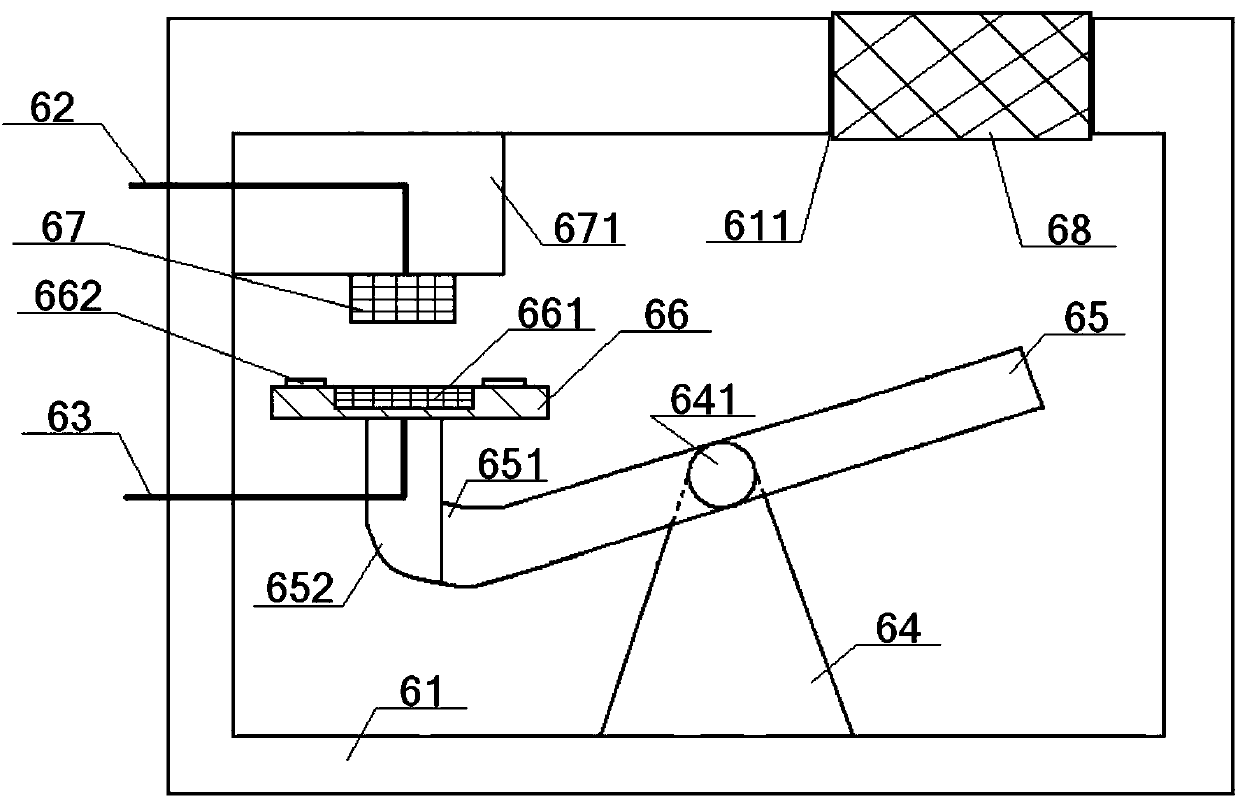

[0027] see Figure 1 to Figure 2 , a straw decomposing furnace for fermentation, comprising a furnace main body 1, a decomposer 5, a drive shaft 7, a filter channel 3 and an output channel 4, the inside of the furnace main body 1 is provided with a decomposer 5, and the middle part of the decomposer 5 runs through and There is a drive shaft 7, the top and bottom ends of the drive shaft 7 are respectively connected to the middle of the top bearing 73 and the bottom bearing 74, and the bottom of the furnace main body 1 communicates with the output channel 4 through the filter channel 3;

[0028] The outer wall of the top bearing 73 is connected with the top of the furnace body 1, the outer wall of the bottom bearing 74 is connected with the bottom of the side wall of the furnace body 1 through the support shaft 741, and the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com