Preparation method of anticoccidial drug diclazuril

A technology of diclazuril and anticoccidiostats, applied in the field of drug synthesis, to achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

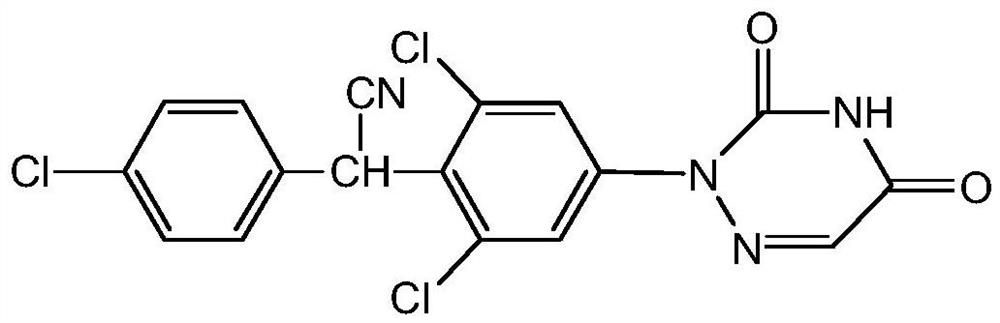

Image

Examples

preparation example Construction

[0021] Preparation of 3,4,5-trichloronitrobenzene

[0022] Put 62.5mL of concentrated sulfuric acid into a 250mL four-necked flask, and add 11.5g of sodium nitrite under stirring. Heat up to 70°C and stir for 10 minutes, then cool down to 55°C, slowly add 31.2 g of 2,6-dichloro-4-nitroaniline, keep warm for 20 minutes, then cool down to 5°C. Add 40 mL of acetic acid dropwise and keep warm for 30 min to prepare a diazo solution.

[0023] In another 250 mL four-necked flask, 125 mL of 36.5% hydrochloric acid and 15 g of cuprous chloride were added, and after stirring for 15 min, the above diazo solution was slowly added dropwise. During the dropping process, the temperature is controlled below 25°C. After the dropwise addition was completed, the temperature was raised to 70° C. and kept for 1 hour. After the heat preservation is over, cool down to normal temperature and filter, and wash with 1% lye. The brown crystal obtained by filtration was recrystallized with ethanol, th...

Embodiment 1

[0025] Preparation of 2,6-dichloro-α-(4-chlorophenyl)-4-nitrophenylacetonitrile

[0026] 170 mL of 2-butanone, 55 g of 3,4,5-trichloronitrobenzene, and 40.5 g of p-chlorophenylacetonitrile were put into a 500 mL four-necked flask, and the temperature was raised to 50°C. Add 50% sodium hydroxide solution dropwise, and keep the reaction for 2 hours after dropping. After the heat preservation was completed, the temperature was lowered to 25° C. and hydrochloric acid was added dropwise to adjust the pH=2. After adding 70mL of water, the temperature was raised to 50°C and the layers were separated. The water layer was removed, and the organic layer was distilled under reduced pressure to collect 2-butanone for recycling. Add methanol and cool down to 20° C., and filter to obtain 74.7 g of light yellow powder of the condensate with a yield of 90% and a content of 99.59% (HPLC).

[0027] Preparation of 2,6-dichloro-α-(4-chlorophenyl)-4-aminophenylacetonitrile

[0028] Into a 500 ...

Embodiment 2

[0032] Preparation of 2,6-dichloro-α-(4-chlorophenyl)-4-nitrophenylacetonitrile

[0033] 200 mL of 2-butanone, 55 g of 3,4,5-trichloronitrobenzene, and 42.4 g of p-chlorophenylacetonitrile were put into a 500 mL four-necked flask, and the temperature was raised to 50°C. Add 30% sodium hydroxide solution dropwise, and keep the reaction for 3 hours after dropping. After the heat preservation was completed, the temperature was lowered to 30° C. and hydrochloric acid was added dropwise to adjust the pH to 1. After adding 55mL of water, the temperature was raised to 55°C and the layers were separated. The water layer was removed, and the organic layer was distilled under reduced pressure to collect 2-butanone for recycling. Add methanol and cool down to 20° C., and filter to obtain 73.04 g of light yellow powder of the condensate with a yield of 88% and a content of 99.3% (HPLC).

[0034] Preparation of 2,6-dichloro-α-(4-chlorophenyl)-4-aminophenylacetonitrile

[0035] Into a 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com