Automatic environment-friendly coating reflective heat-insulating coating wallboard continuous production system

A reflective heat-insulating paint, automatic coating technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of waste coating efficiency, troublesome coating operation, uneven coating, etc. Coating utilization rate, good coating effect, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

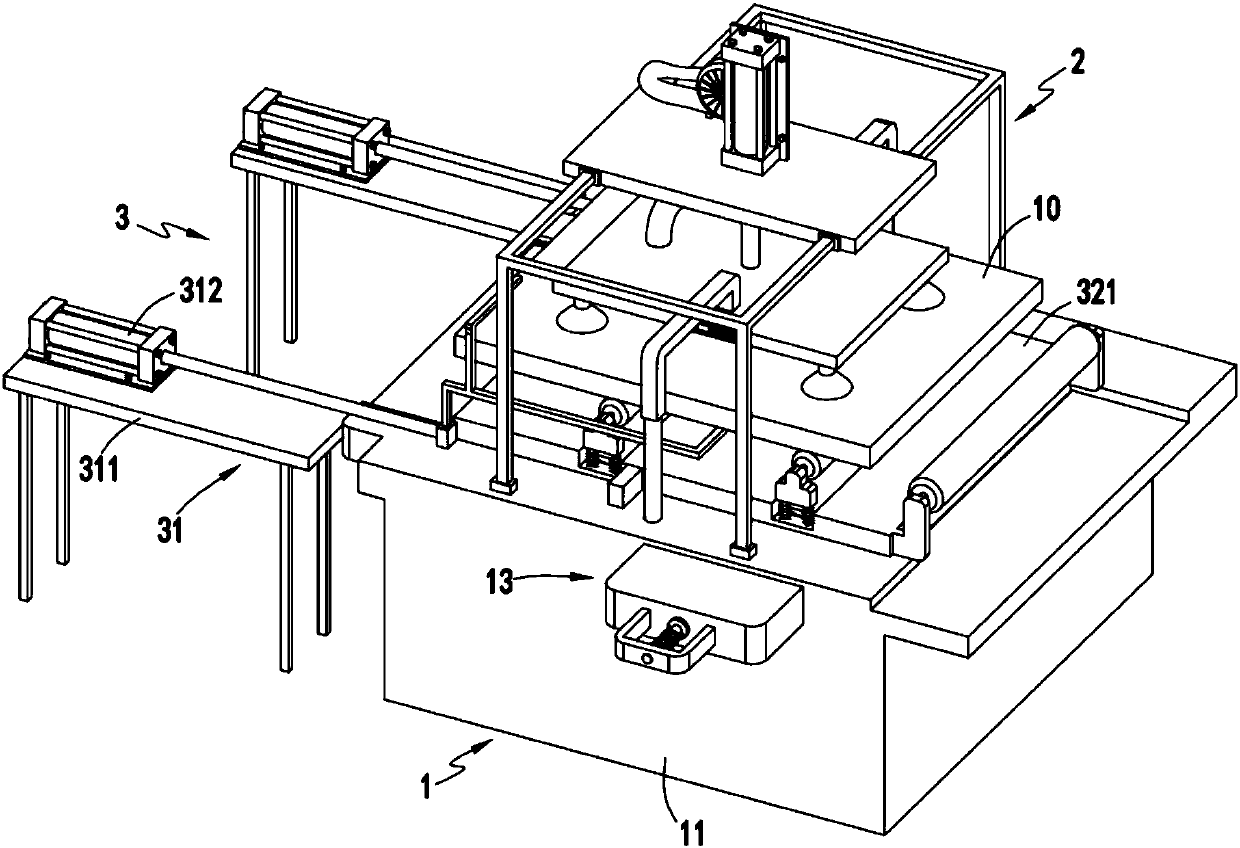

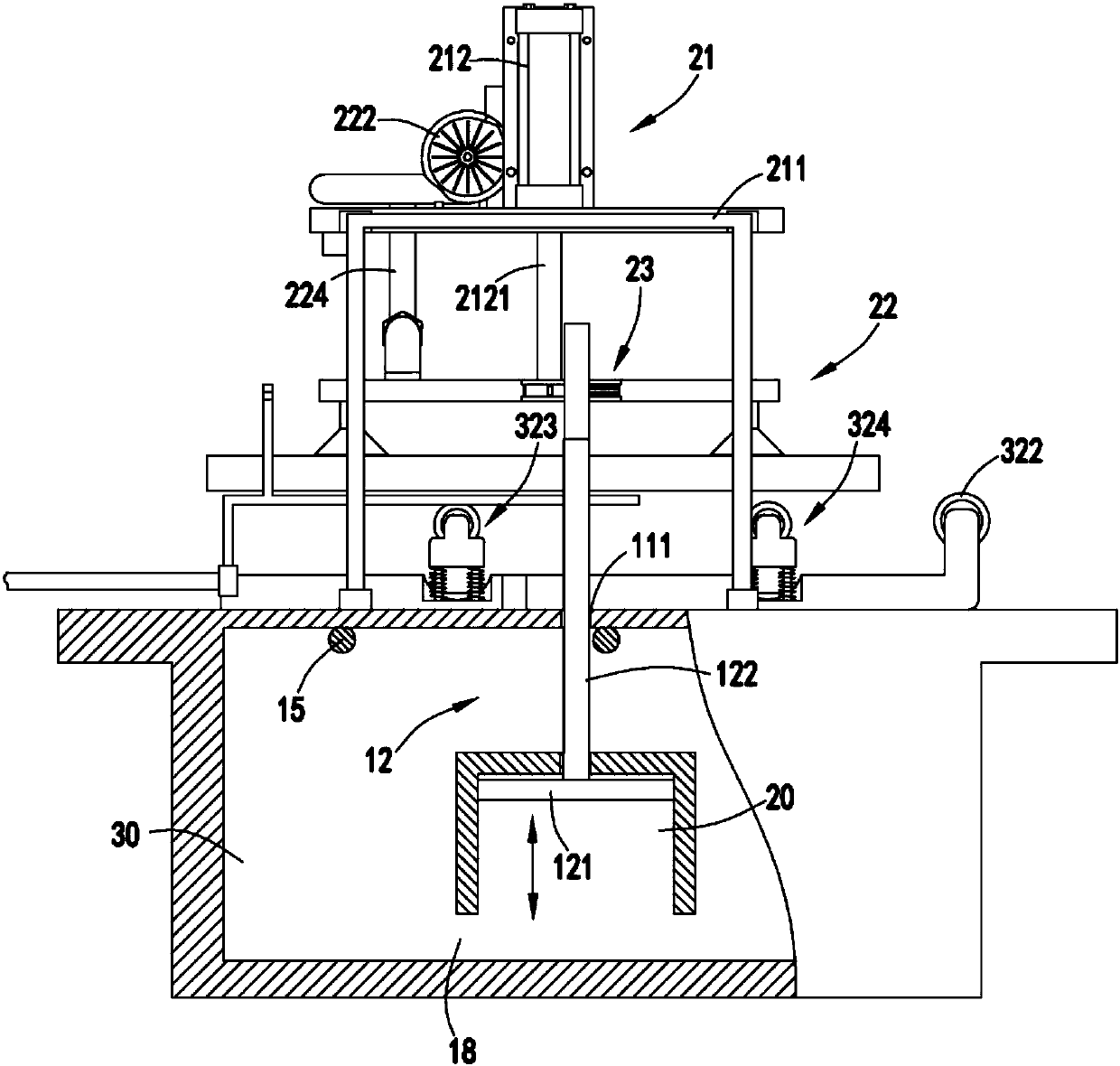

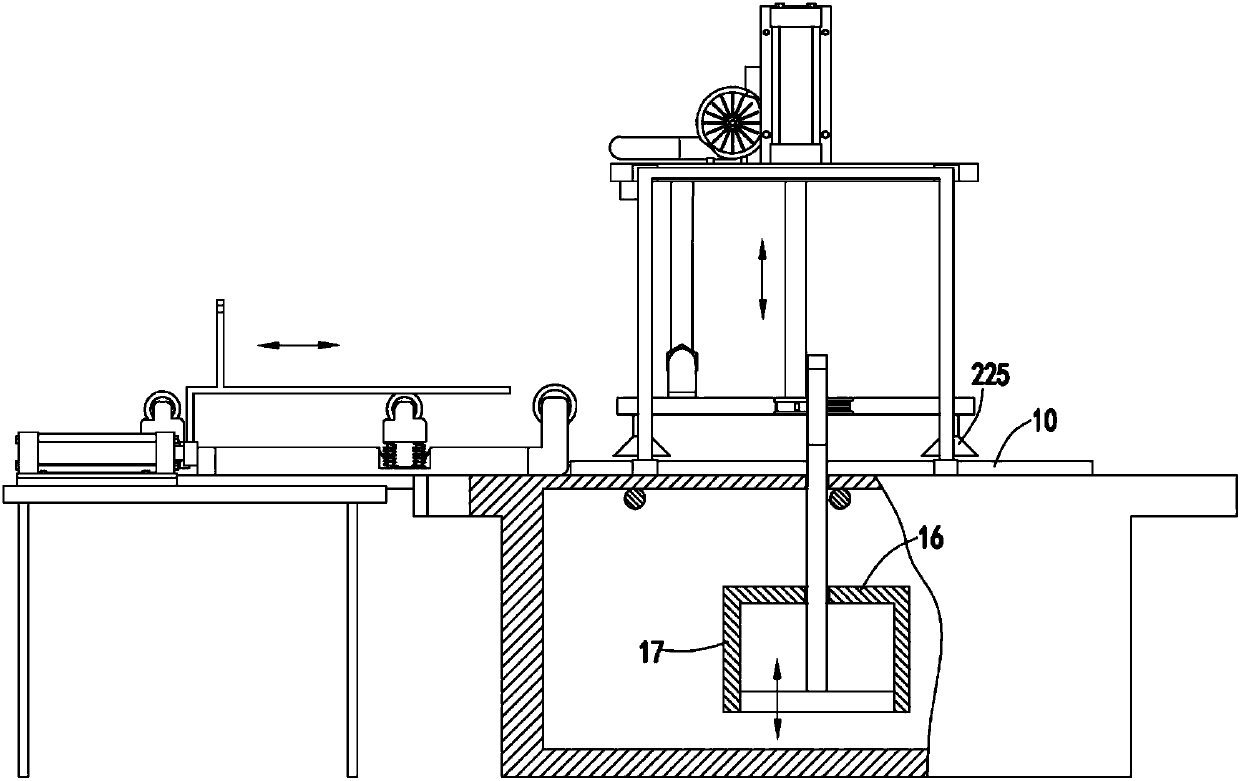

[0043] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the environment-friendly continuous production system for automatic coating of reflective heat insulation paint wall panels includes

[0044] Coating device 1, the coating device 1 includes a box body 11, an extrusion mechanism 12 arranged in the box body 11 and an overflow mechanism 13 arranged on the side of the box body 11, the upper surface of the box body 11 is provided with Coating port 14, the extruding mechanism 12 is used to extrude the paint in the box body 11 to raise the liquid level of the paint to coat the lower surface of the plate 10 located at the coating port 14;

[0045] Lifting device 2, described lifting device 2 is arranged on the top of box body 11, and this lifting device 2 comprises the lifting mechanism 21 that is installed on the box body 11, the adsorption mechanism 22 that carries out adsorption transfer to plate 10 ...

Embodiment 2

[0062] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the overflow mechanism 13 includes an overflow box 131, an overflow block 132 that slides with the inner wall of the overflow box 131, and is arranged on the overflow box 131. The support member 133 on one side and the guide rod 136 that slides with the guide hole b134 provided on the side of the overflow box 131 and the guide hole c135 provided on the support member 133, one end of the guide rod 136 and the overflow block 132 Fixedly connected, the guide rod 136 is provided with a limit block 137 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com