Method for manufacturing thin-film resistor through ICP dry etching

A thin-film resistor and dry etching technology, which is applied in the direction of resistors, circuits, electrical components, etc., can solve the problems of slow etching rate, poor controllability of key dimensions, and difficult control of substrate damage, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

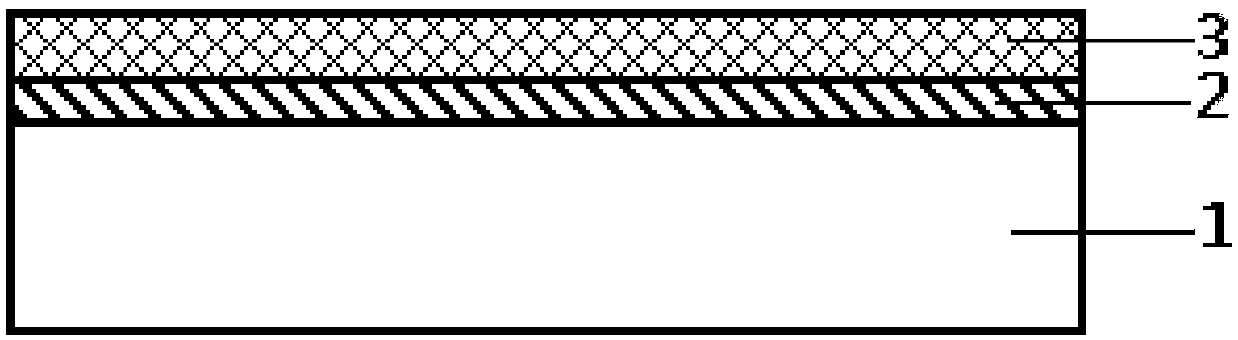

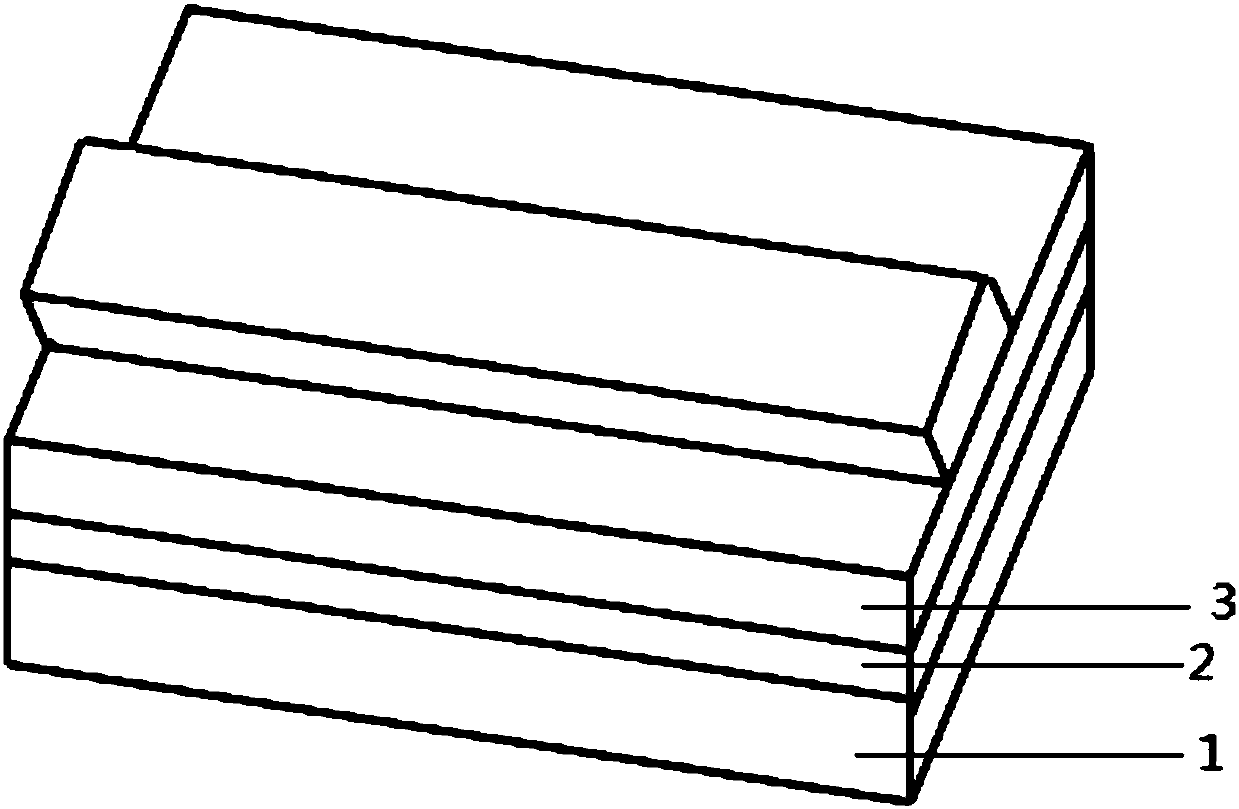

[0039] A method for manufacturing thin-film resistors by ICP dry etching, which is characterized by comprising: a substrate dielectric layer 1, a thin-film resistor layer 2, a mask layer 3, a dielectric layer 4, an isolation layer 5 and a metal layer 6.

[0040] Do the following steps:

[0041] 1) Deposit a resistive thin film layer 2 on the substrate dielectric layer 1 .

[0042] The resistive film layer 2 in the step 1) is a metal film containing Cr, including CrSi.

[0043] 2) Depositing a masking layer 3 on the resistive thin film layer 2 .

[0044] The masking layer 3 in the step 2) is a material with a high selectivity ratio, and the masking layer 3 includes Ti or Tin.

[0045] The selection ratio of the material of the resistive film layer 2 and the material of the masking layer 3 is greater than or equal to 6.

[0046] 3) Removing the resistive thin film layer 2 and the masking layer 3 by ICP dry etching to form a resistive pattern.

[0047] In the step 3), ICP pla...

Embodiment 2

[0057] A method for manufacturing thin-film resistors by ICP dry etching, which is characterized by comprising: a substrate dielectric layer 1, a thin-film resistor layer 2, a mask layer 3, a dielectric layer 4, an isolation layer 5 and a metal layer 6.

[0058] Do the following steps:

[0059] 1) if figure 1 As shown, a resistive thin film layer 2 is deposited on the substrate dielectric layer 1 .

[0060] The substrate dielectric layer 1 is an insulating medium;

[0061] The resistance film layer 2 is CrSi, and the thickness of the resistance film layer 2 is 45±5nm;

[0062] 2) if figure 1 A masking layer 3 is deposited on the resistive film layer 2 as shown.

[0063] The masking layer 3 in the step 2) is a material with a high selectivity ratio, and the masking layer 3 includes Ti or Tin; the thickness of the masking layer 3 is about 10±1 nm.

[0064] The selection ratio of the material of the resistive film layer 2 and the material of the masking layer 3 is greater than...

Embodiment 3

[0082] In this embodiment, the specific parameters for etching the CRSI metal layer by ICP are shown in Table 1:

[0083] Table 1

[0084]

[0085]

[0086] specific:

[0087] Utilize the OMEGA machine platform of TRIKON Company in the present invention, adopt the mode of two-step etching:

[0088] In the first step, the etching gas used is Cl 2 , HBr and Ar, and through the way of endpoint detection, used to etch most metals;

[0089] In the present invention, the first etching step adopts Cl 2 , the flow rate of HBr and Ar can be adjusted according to the composition of the metal film and the etching requirements, where Cl 2 As the main etching gas, Ar mainly provides physical bombardment; HBr is used for auxiliary etching and sidewall protection;

[0090] In the first step of etching, the etching end point is detected by means of end point detection. In this embodiment, the 55±6nm masking layer / CRSI film reaches the end point within 12-18 sec, and the etching rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com