Multi-surface display

A display and panel technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of single-sided display and limited display angle of the display, and achieve the effect of prolonging the service life and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

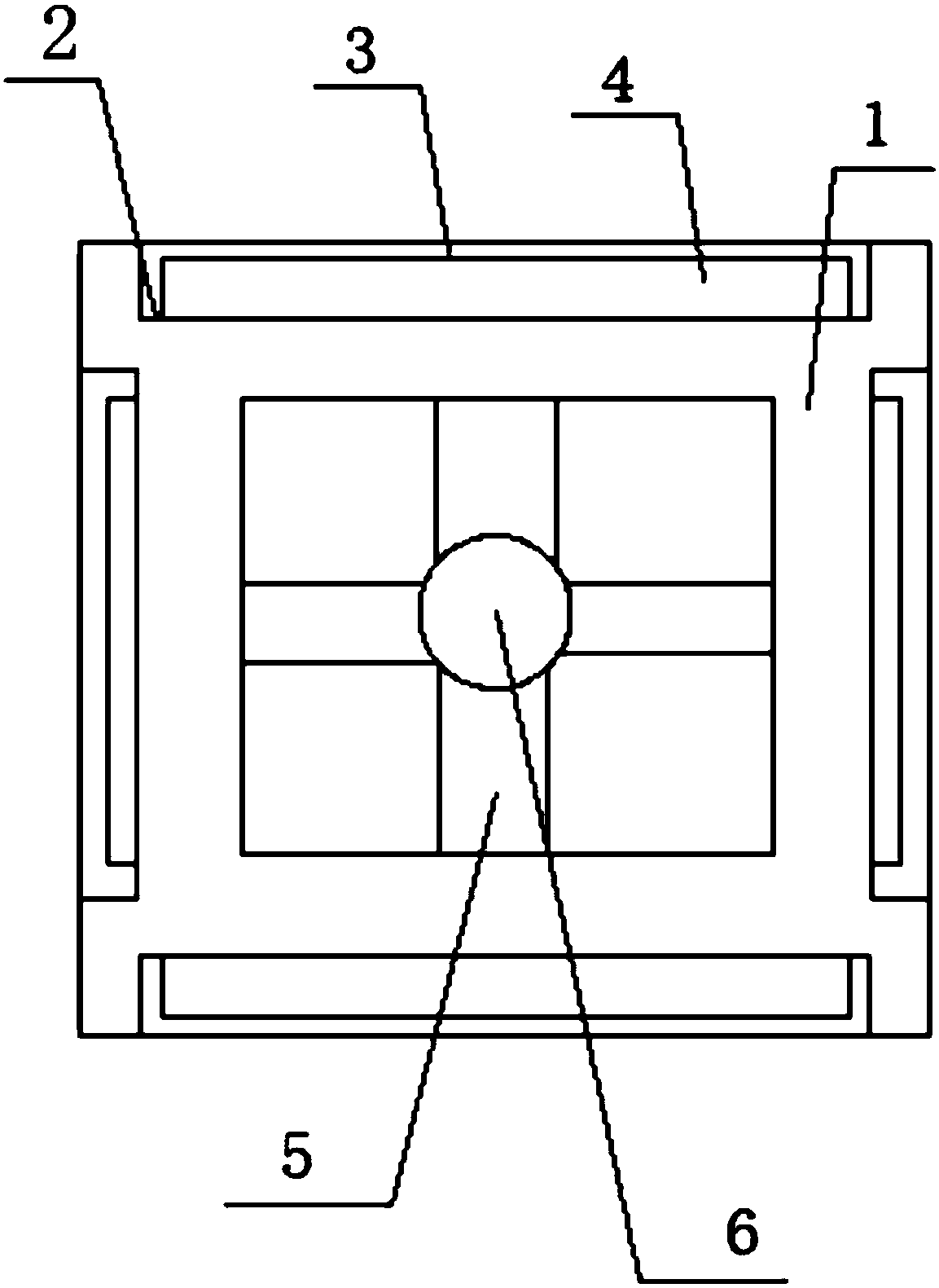

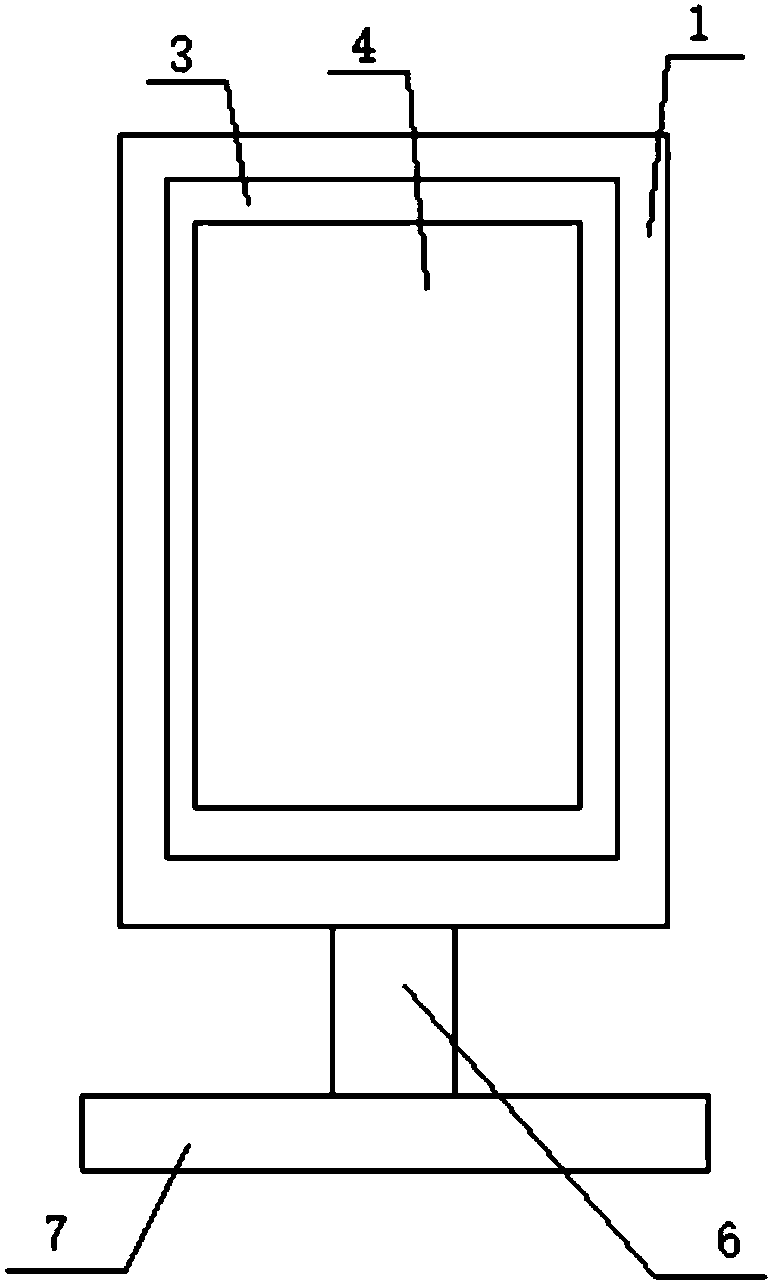

[0030] see Figure 1 to Figure 2 , the present invention provides a multi-faceted display, comprising: a square cylindrical backplane 1, a panel placement slot 2, a front frame 3, a liquid crystal panel 4, a connecting rod 5, a rotating shaft 6 and a base 7; the rotating shaft 6 is vertically arranged on the on the base 7, and is rotatably connected with the base 7; the connecting rods 5 are evenly arranged on the peripheral surface of the rotating shaft 6; the number of the connecting rods 5 is 4; the square cylindrical backboard 1 is sleeved On the outside of the rotating shaft 6, the connecting rod 5 is connected to the inner wall of the square cylindrical backboard 1; the four sides of the square cylindrical backboard 1 are provided with panel placement grooves 2, and the liquid crystal panel 4 is provided with In the panel placement groove 2 , the front frame 3 is disposed in the panel placement groove 2 and located in front of the liquid crystal panel 4 . The outer surf...

Embodiment 2

[0033] A method for manufacturing a support mechanism of a multi-faceted display, the steps are as follows:

[0034] 1), structure and separate processing

[0035] The supporting mechanism includes a square tube-shaped back plate, the four sides of the square tube-shaped back plate are provided with panel placement grooves, the liquid crystal panel is arranged in the panel placement groove, the front frame is arranged in the panel placement groove, and is located in front of the liquid crystal panel;

[0036] The square tube-shaped back panel is made of carbon steel, and the processing method is casting, and the panel placement groove is formed by integral casting;

[0037] The material of the front frame is acrylic, which is made by extrusion;

[0038] 2), protective treatment

[0039] Spray protective liquid on the surface of the support mechanism, then wash and dry directly;

[0040] The protective liquid components are: 2.5 parts of tricresyl phosphate, 15 parts of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com