Cold start method of gas-and-steam combined cycle power generating unit

A technology of combined cycle and generator set, which is applied in the direction of engine starting, steam engine device, gas turbine device, etc. It can solve the problems of long warm-up time at medium speed, inability to meet fast start-up support grid, and long start-up time in cold state. time, enhance the warm-up effect, and increase the effect of steam intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

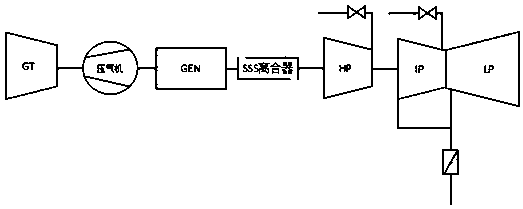

[0025] Such as figure 1 As shown, the gas-steam combined cycle generator set includes a steam turbine (HP+IP+LP), a gas turbine (GT+compressor+GEN) and an SSS clutch. The steam turbine is coupled to the gas turbine through the SSS clutch. The steam turbine includes a high-pressure cylinder and a medium-pressure cylinder and low pressure cylinders.

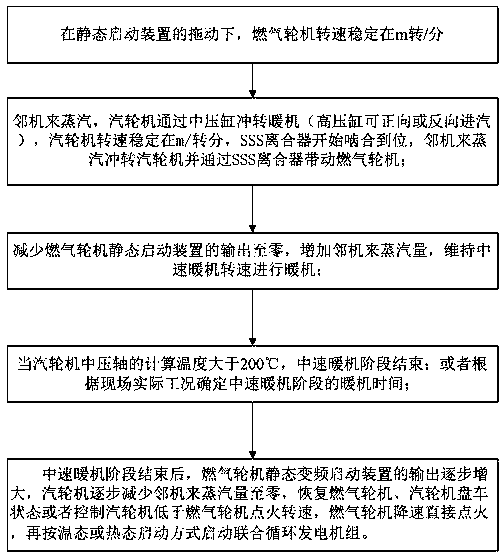

[0026] Such as figure 2 As shown, the method provided by the invention specifically includes the following steps:

[0027] The first step, the gas turbine starts the modified cleaning program. Under the drag of SFC, the speed of the gas turbine is stable at about 700 rpm (between 600 rpm and 900 rpm).

[0028] The second step, the steam comes from the adjacent machine, the medium-pressure cylinder rushes to turn the steam turbine to warm up (the high-pressure cylinder can enter steam in the forward or reverse direction), and the steam turbine speed is brought to about 700 rpm (600 rpm-900 rpm) ), synchronized with the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com