Construction technology of pre-embedded steel edge waterstop and waterstop steel plate for integrated pipe gallery

A technology of water-stop steel plate and integrated pipe gallery, which is applied in the field of construction engineering, can solve the problems of pre-embedded steel edge water-stop belt and side wall water-stop steel plate position offset, etc., so as to reduce displacement deviation, improve construction efficiency, and ensure construction. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

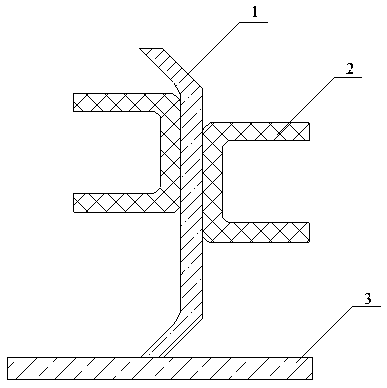

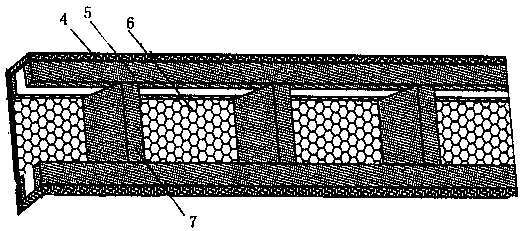

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a construction technology of pre-embedded steel edge waterstop and waterstop steel plate reinforcement for comprehensive pipe gallery includes steps:

[0032] 1) At the bottom of the water-stop steel plate 1 on the side wall, set a positioning rib 3 horizontally at intervals of 1.5-2.5 meters to support the water-stop steel plate 1, and the positioning rib 3 is welded and fixed on the steel skeleton to prevent the water-stop steel plate 1 from longitudinally shifting.

[0033] 2) Install the waterproof steel plate 1.

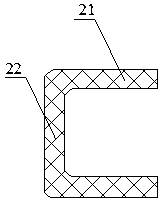

[0034] 3) Install several pairs of U-shaped reinforcement bars 2 on the left and right sides of the water-stop steel plate 1, and squeeze the water-stop steel plate 1 tightly; The water-stop steel plate 1 and the two side parts 21 of the U-shaped reinforced steel bar 2 are welded to the steel bar skeleton to prevent the lateral deviation of the water-stop steel plate 1; the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com