A hingeless rocker slider mechanism and a weft-connecting rapier for rapier looms

A rocker slider, rapier loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as hinge shaft flying out, excessive warp tension change, and breaking cloth, etc., to improve clamping force, improve adaptability, and stabilize the yarn clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

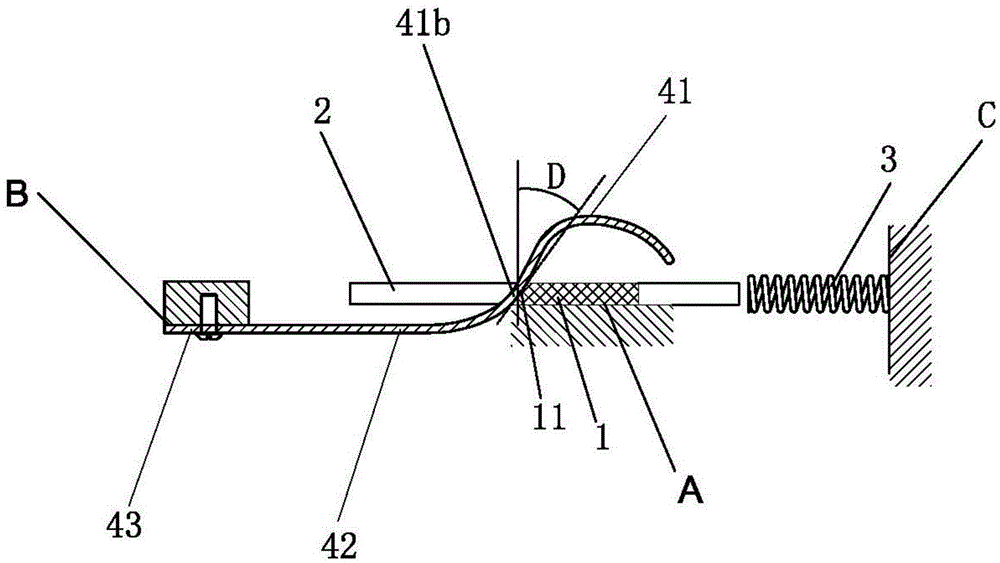

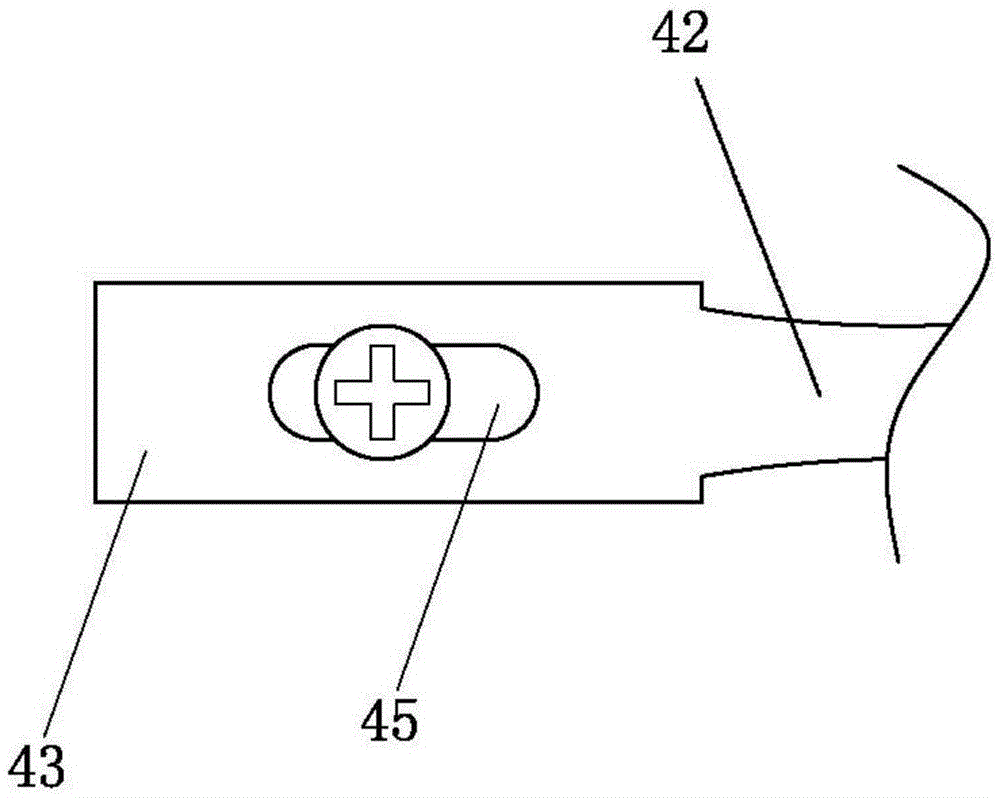

[0036] Reference attached Figure 1-2 , A hingeless rocker slider mechanism, including a rocker, a slider 1 roughly in the shape of a rectangular parallelepiped, the slider 1 is slidably arranged on the plane A, and the slider 1 is provided with a connecting part 2 fixed with the load. One end of the positioning spring 3 abuts against the connecting part 2 and the other end of the return spring 3 abuts against a plane C perpendicular to the plane A. The return spring 3 drives the slider 1 to return to drive the load back. The rocker is an elastic component. The rocker includes a driving part, an elastic deformation part 42 and a positioning part 43. The positioning part 43 is provided with a long waist hole 45. The bolt overlong waist hole 45 is fixed to plane B. Plane B is located on the left of plane A. Side; planes A, B, and C are all planes of the machine body, such as the sword head shell of the weft sword head, the shell of the travel switch, etc.; the driving part include...

Embodiment 2

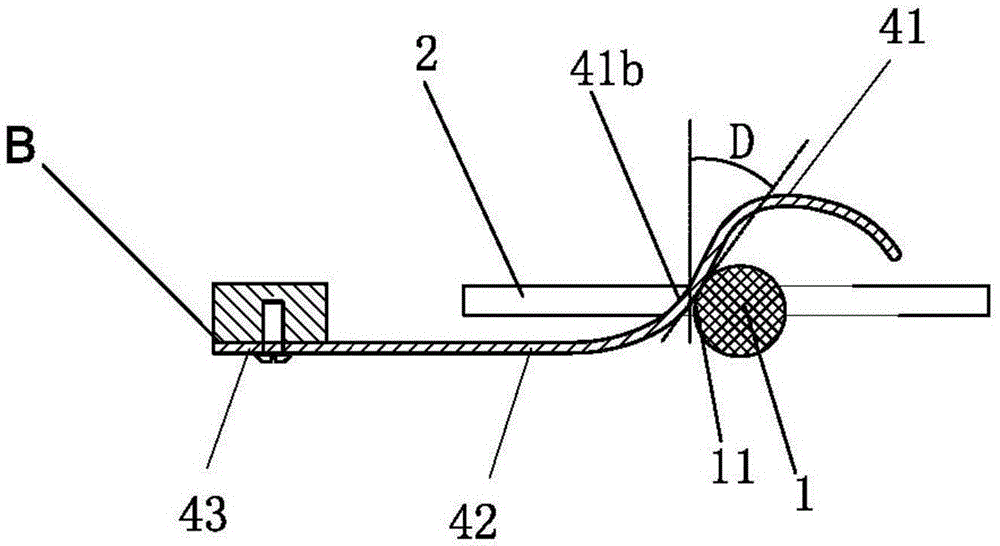

[0040] See Figure 4 The difference between Embodiment 2 and Embodiment 1 is that the other end of the elastically deformable part is connected to one end of the input part 41, the other end of the input part 41 is connected to the output part 41b, and the shape of the output part 41b and the input part 41 is a circle. shape.

Embodiment 3

[0042] See Figure 5 The difference between embodiment 3 and embodiment 1 is that one end of the positioning portion 43 is connected to one end of the elastic deformation portion 42, the other end of the elastic deformation portion 42 is connected to one end of the input portion 41, and the other end of the input portion 41 is connected to the output portion. 41b is connected, and the shape formed by the input part 41 and the output part 41b is an arched bridge shape, and the part of the output part 41b abuts against the inclined surface of the upper left corner of the slider.

[0043] Such as Image 6 As shown in the structure, the hingeless rocker slider mechanism of the present invention can also be transformed into this structure. The structure includes a rocker and a slider 1 with a rectangular cross-sectional shape. The slider 1 is slidably arranged on the plane A. 1 is provided with a connecting portion 2 fixed with a load, one end of the return spring 3 abuts against the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com