Novel oil cylinder pressurizing and lifting device for blast hole drilling machine

A blasting hole and oil cylinder technology is applied in the field of mining machinery to achieve the effects of improving system stability, easy implementation and saving the number of pulleys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

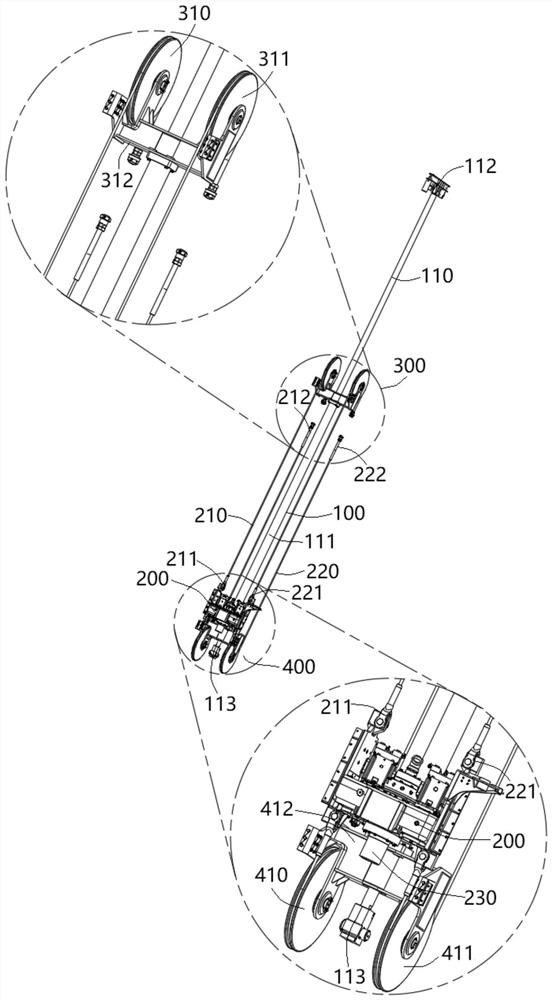

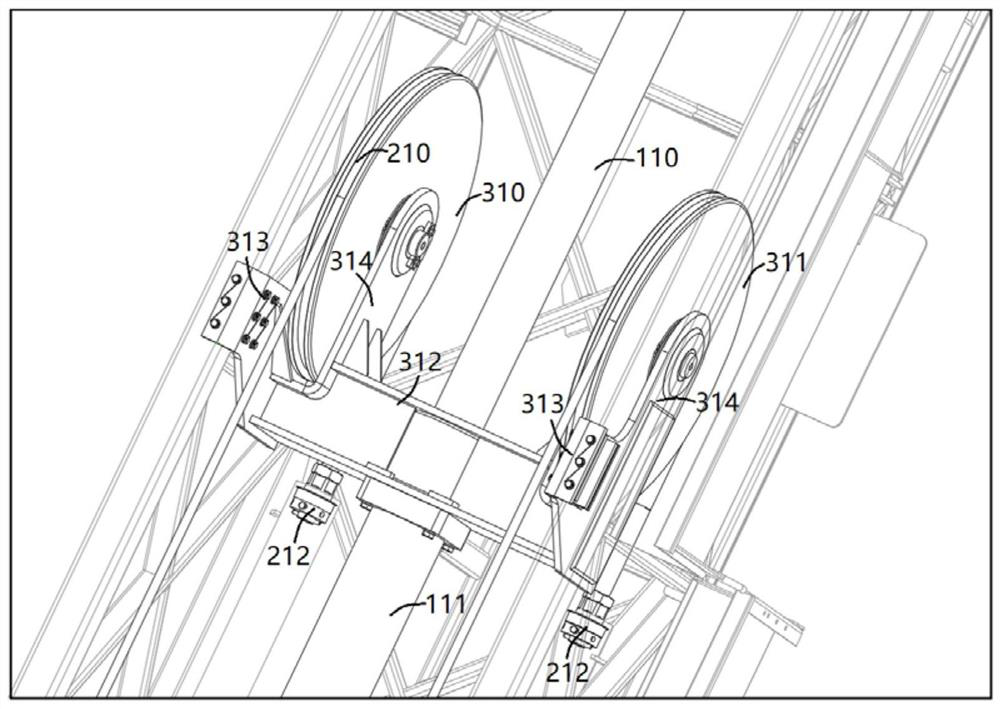

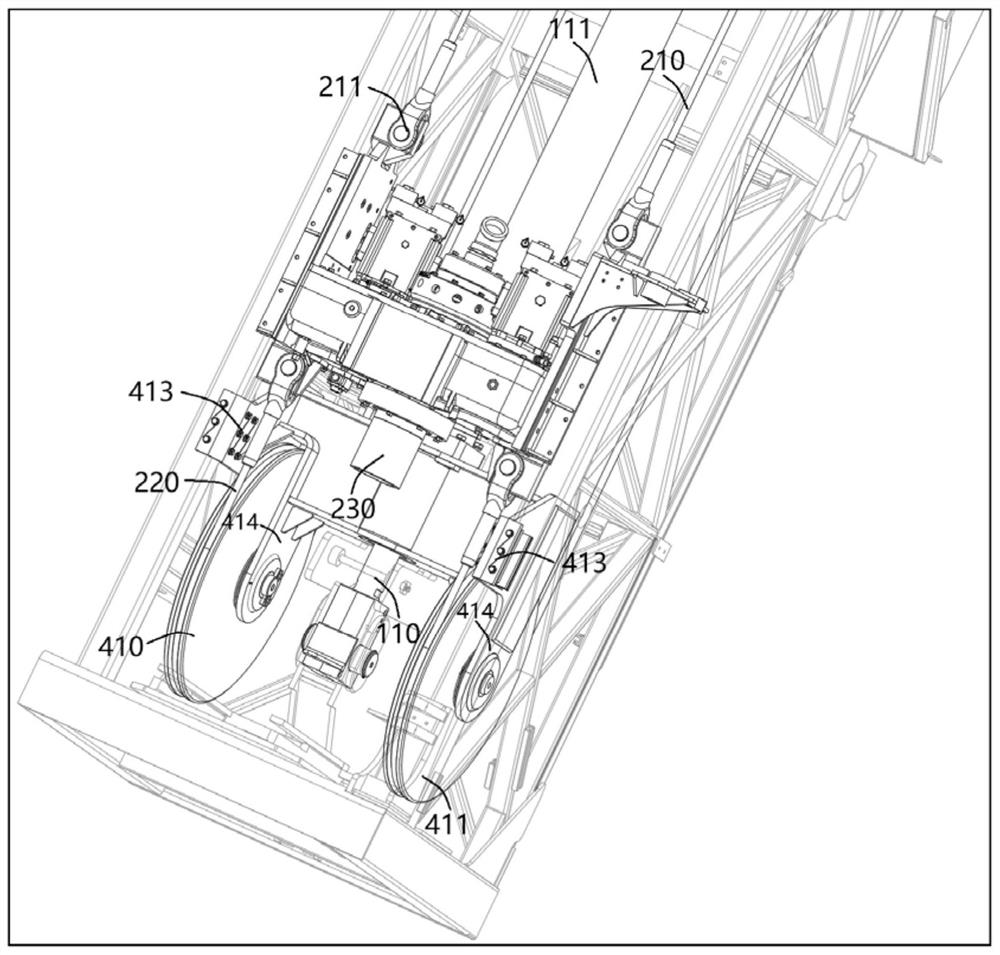

[0040] combine figure 1 , Figure 4 and Figure 5 , a new type of oil cylinder pressurized lifting device for a blast hole drilling rig in this embodiment, including a tower device 500 and an oil cylinder 100 arranged in the tower device 500, the oil cylinder 100 includes a piston rod 110 and a cylinder barrel 111, the piston rod The two ends of 110 are fixed on the tower device 500, and the cylinder barrel 111 slides up and down along the piston rod 110; the two ends of the cylinder barrel 111 are provided with a pulley frame for installing the upper driving wheel 300 and the lower driving wheel 400, and the upper driving wheel 300 and the lower driving wheel A power head 200 is arranged between the driving wheels 400, and the two ends of the power head 200 are respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com