Preparation method of black Bi4Ti3O12 material and application thereof

A black, certain amount of technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of narrow response range and consumption of photocatalytic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

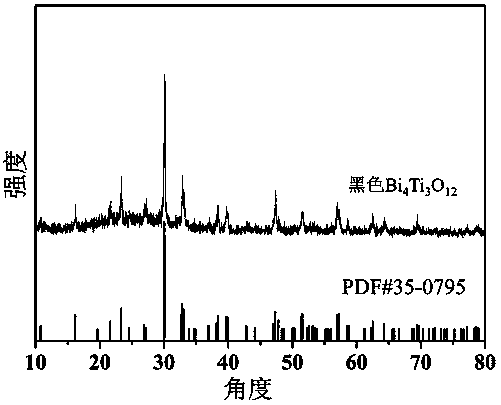

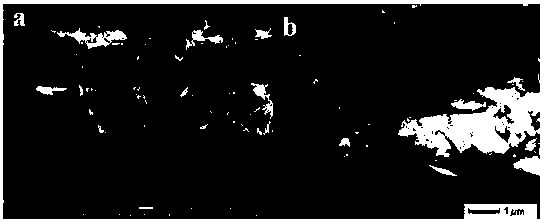

[0024] (1) Bi 4 Ti 3 o 12 Preparation of materials:

[0025] Grind 0.47 g of bismuth oxide, 1.7 g of sodium chloride and 2.2 g of potassium chloride evenly, then add 0.12 g of P25 and grind them evenly; Calcined at ℃ for 2 h, cooled naturally, washed with deionized water, and dried to obtain Bi 4 Ti 3 o 12 Material.

[0026] (2) Black Bi 4 Ti 3 o 12 Preparation of materials:

[0027] 0.5 g Bi 4 Ti 3 o 12 Materials with 0.1 g NaBH 4 Grind fully and evenly, and put the mixture in a tube furnace at 300°C for calcination for 30 min under the condition of feeding argon protective gas, cool to room temperature naturally, wash with deionized water until neutral, and dry to obtain black Bi 4 Ti 3 o 12 Material.

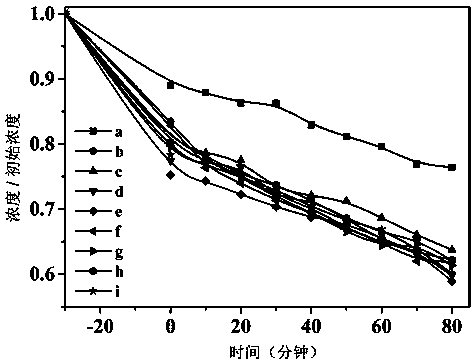

[0028] (3) Photocatalytic degradation test:

[0029] Take the black Bi in step (2) 4 Ti 3 o 12 The photocatalytic degradation test was carried out on the material samples in a photochemical reaction apparatus, and the degradation rate of tetracycline by t...

Embodiment 2

[0031] (1) Bi 4 Ti 3 o 12 Preparation of materials:

[0032] Grind 0.47 g of bismuth oxide, 1.7 g of sodium chloride and 2.2 g of potassium chloride evenly, then add 0.12 g of P25 to grind evenly; put the above mixture into a muffle furnace for high-temperature calcination, calcination at 750°C for 2 h, and cool naturally , washed with deionized water, and dried to obtain Bi 4 Ti 3 o 12 Material.

[0033] (2) Black Bi 4 Ti 3 o 12 Preparation of materials:

[0034] 0.6 g Bi 4 Ti 3 o 12 Materials with 0.1 g NaBH 4 Grind fully and evenly, and put the mixture in a tube furnace at 300°C for calcination for 30 min under the condition of feeding argon protective gas, cool to room temperature naturally, wash with deionized water until neutral, and dry to obtain black Bi 4 Ti 3 o 12 Material.

[0035] (3) Photocatalytic degradation test:

[0036] Take the black Bi in step (2) 4 Ti 3 o 12 The photocatalytic degradation test of the material samples was carried out in...

Embodiment 3

[0038] (1) Bi 4 Ti 3 o 12 Preparation of materials:

[0039] Grind 0.47 g of bismuth oxide, 1.7 g of sodium chloride, and 2.2 g of potassium chloride evenly, then add 0.12 g of P25 to grind evenly; put the above mixture into a muffle furnace for high-temperature calcination at 750°C for 2 h, and cool naturally. Washed with deionized water and dried to obtain Bi 4 Ti 3 o 12 Material.

[0040] (2) Black Bi 4 Ti 3 o 12 Preparation of materials:

[0041] 0.7 g Bi 4 Ti 3 o 12 Materials with 0.1 g NaBH 4 Grind fully and evenly, and put the mixture in a tube furnace at 300°C for calcination for 30 min under the condition of feeding argon protective gas, cool to room temperature naturally, wash with deionized water until neutral, and dry to obtain black Bi 4 Ti 3 o 12 Material.

[0042] (3) Photocatalytic degradation test:

[0043] Take the black Bi in step (2) 4 Ti 3 o 12 The photocatalytic degradation test of the material samples was carried out in a photochemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com