Soft capsules made from okra seed oil and preparation method of soft capsules

A technology of okra seeds and soft capsules is applied in the directions of fat oil/fat production, fat production, food ingredient functions, etc., can solve problems such as difficulty in industrial production, low nutrient activity, unfavorable human health, etc. Fast effect and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

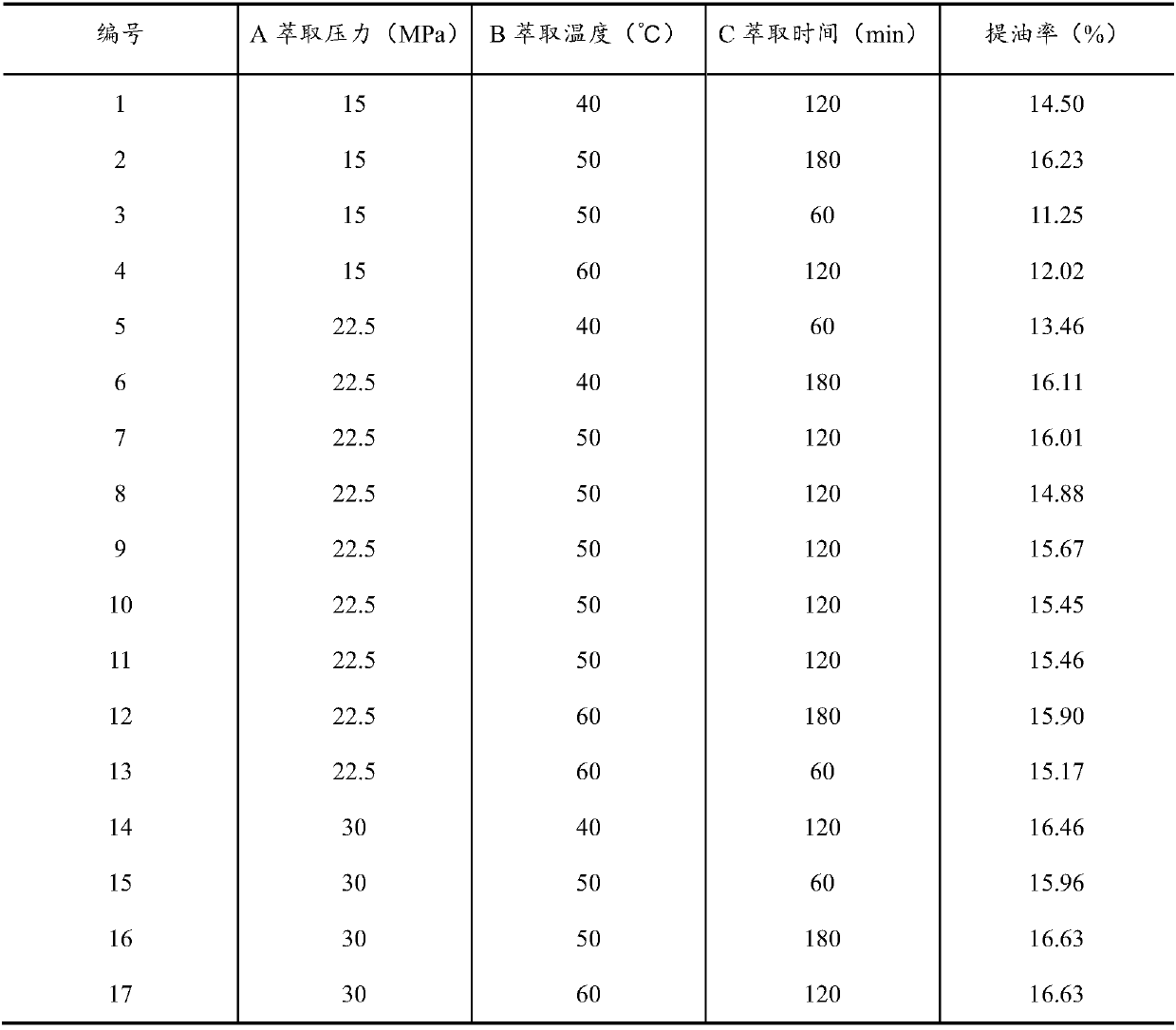

[0026] 1) Using supercritical CO 2 The extraction method extracts okra seed oil, including: selecting mature okra seeds, pulverizing them through a high-speed pulverizer, passing through a 20-mesh sieve, and filling them with supercritical CO 2 In the extraction kettle, in CO 2 The flow rate is 32L / h, the pressure is 25MPa, and the temperature is 40°C, extracting for 3 hours, collecting okra seed oil at the outlet of the extraction kettle, the yield of okra seed oil = the quality of the extracted oil / mass of raw materials × 100%, and the yield is 16.20%;

[0027] 2) the quantitative soybean oil is subjected to freezing-thawing method to remove the saturated fatty acid ester therein, the okra seed oil obtained in step 1) is mixed with the soybean oil from which the saturated fatty acid ester has been removed in a mass ratio of 1:7, Stir in an electric mixer at 100-150r / min for 30min until uniform, and filter through a 0.45μm microporous filter membrane and a vertically fused g...

Embodiment 2

[0033] 1) Using supercritical CO 2 The extraction method extracts okra seed oil, including: selecting mature okra seeds, pulverizing them through a high-speed pulverizer, passing through a 40-mesh sieve, and filling them with supercritical CO 2 In the extraction kettle, in CO 2 The flow rate is 40L / h, the pressure is 15MPa, and the temperature is 50°C, and the extraction is carried out for 2 hours, and the okra seed oil is collected at the outlet of the extraction kettle. The yield of the okra seed oil = the quality of the extracted oil / the quality of the raw material × 100%, and the yield is 14.50%;

[0034] 2) the quantitative soybean oil is subjected to freezing-thawing method to remove the saturated fatty acid ester therein, the okra seed oil obtained in step 1) is mixed with the soybean oil from which the saturated fatty acid ester has been removed in a mass ratio of 1:8, Stir in an electric mixer at 100-150r / min for 50min until uniform, and filter through a 0.45μm micro...

Embodiment 3

[0040] 1) Using supercritical CO 2 The extraction method extracts okra seed oil, including: selecting mature okra seeds, pulverizing them through a high-speed pulverizer, passing through a 60-mesh sieve, and filling them with supercritical CO 2 In the extraction kettle, in CO 2 The flow rate is 30L / h, the pressure is 30MPa, and the temperature is 60°C, extracting for 1 hour, collecting okra seed oil at the outlet of the extraction kettle, the yield of okra seed oil = the quality of the extracted oil / mass of the raw material × 100%, and the yield is 15.75%;

[0041] 2) the quantitative soybean oil is subjected to freezing-thawing method to remove the saturated fatty acid ester therein, the okra seed oil obtained in step 1) is mixed with the soybean oil from which the saturated fatty acid ester has been removed in a mass ratio of 4:7, Stir in an electric mixer at 100-150r / min for 35min until uniform, and filter through a 0.45μm microporous filter membrane and a vertically fused...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com