Wearable telescopic conductive cloth and manufacturing method thereof

A production method and technology of conductive cloth, applied in the direction of bendable/stretchable parts of the circuit, printed circuits, dielectric properties, etc., can solve problems such as easy disconnection, detection failure, and line breakage, so as to increase toughness and Strength, avoiding line breakage, and improving the effect of tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention proposes a wearable stretchable conductive fabric, the conductive fabric body 100 is elastic fabric, and is used to make smart clothing.

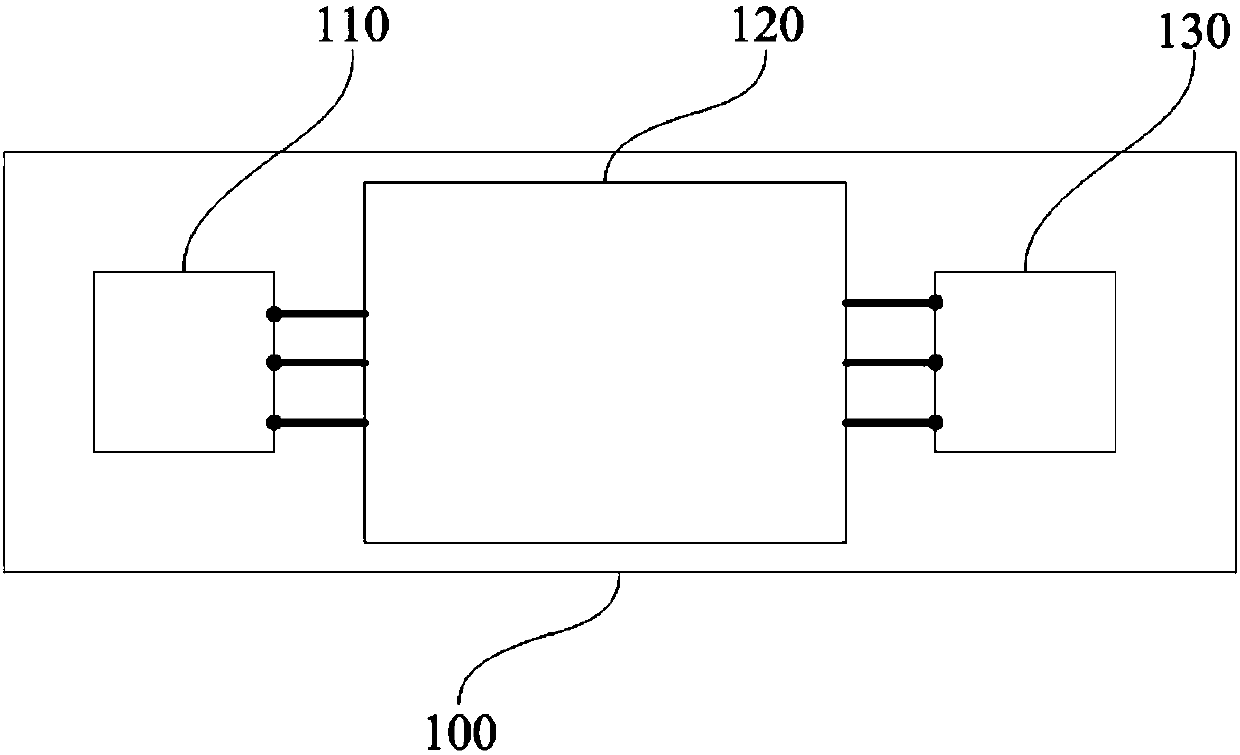

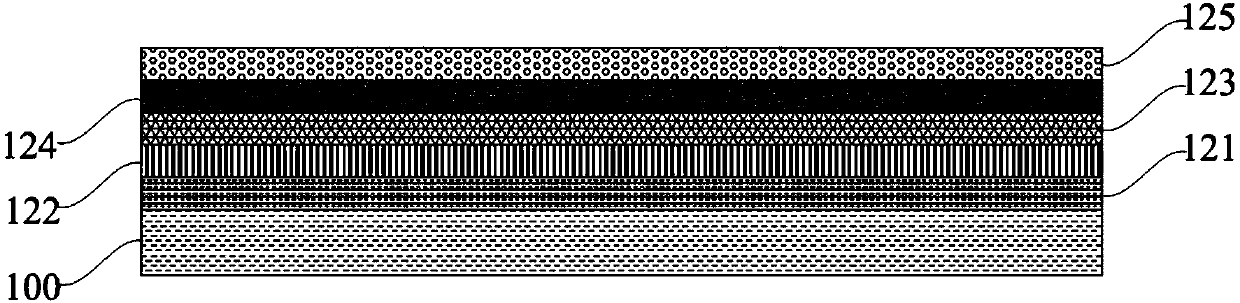

[0034] refer to Figure 1-2 , figure 1 It is a schematic structural diagram of an embodiment of the wearable stretchable conductive cloth of the present invention, figure 2 It is a cross-sectional view of the third area of the wearable stretchable conductive cloth of the present invention.

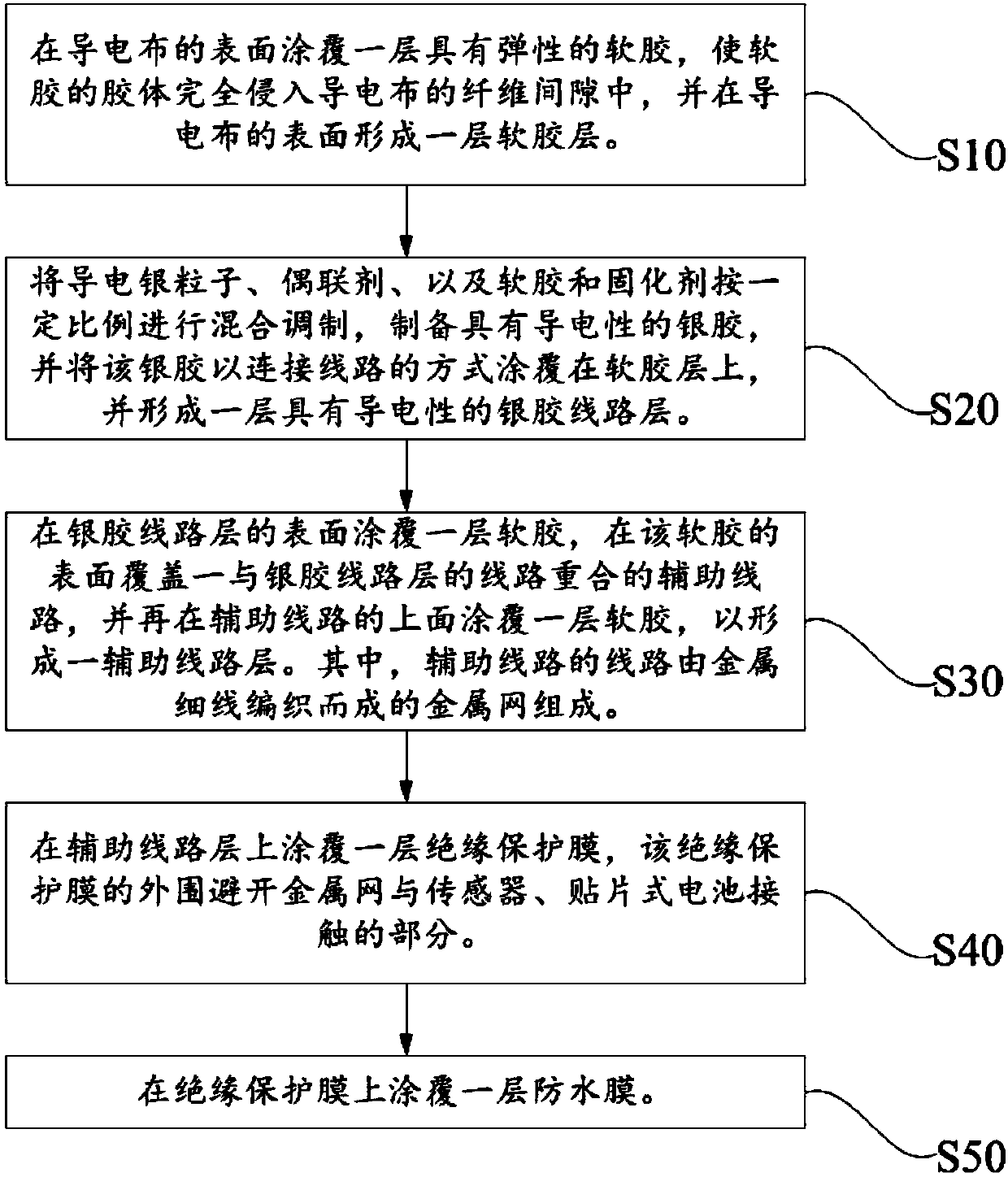

[0035] Such as figure 1 As shown, in the embodiment of the present invention, the surface of the conductive cloth body 100 is provided with: a first area 110 for pasting sensors, a second area 130 for pasting chip batteries, and a printing The third area 120 of the circuit is connected. The first end of the connection circuit is connected with the sensor, and the second end is connected with the patch circuit. Such as figure 2 As shown, the connection circuit on the surface of the third area 120 includes: a soft gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com